Introduction

The Pipeline HUB is home to many tools and calculators. The following user’s manual will outline calculations that cover design, construction, operations, and integrity. The HDD PT User’s Guide presents information, guidelines, and procedures for use during design, construction, operations, and integrity tasks for field or office applications. Horizontal Directional Drilling (HDD) is for professionals involved in the design, engineering, and installation of pipelines and utilities by horizontal directional drilling.

The HDD module provides a means to generate high-level drill designs and/or check and analyze existing designs you may encounter in the field. The underlying mathematical models and technical procedures are based on the latest HDD technology and are following current regulations, standards, and recommended practices. The HDD module provides standard stress and pull force analysis for steel, drilling fluid, and pressure analysis, and addresses the installation of cables in conduits.

Mud Management

Inadvertent returns of the drilling fluid to the surface are often a significant issue for HDD installations. Even though the drilling fluid is usually a non-toxic fluid containing mainly fresh water and 1% to 3% bentonite, accidental surface returns can be detrimental. The risk of inadvertent returns can be reduced by proper HDD design and good drilling practices.

Hydro-fracture occurs in non-fissured cohesive soils when the pressure gradient in the borehole exceeds the formation pressure gradient. This happens when the drilling fluid pressure exceeds the strength and confining stress of the surrounding soils. Under these conditions, the pressure fractures the soil around the borehole wall and allows the drilling fluid to escape the annulus. The likelihood of this occurring is often modeled with the cavity expansion model

The cavity expansion model can be used to calculate the estimated maximum allowable drilling fluid pressure in a borehole. The risk of hydrofracture can be evaluated by calculating the maximum allowable pressure with the following cavity expansion equation (often referred to as the Delft Equation). The minimum required pressure needs to be considerably lower than the maximum allowed pressure to reduce the chance of hydrofracture.

Initial Ground Water Pressure:

\mu = \gamma_{\text{water}} (h_w)

\mu = \gamma_{\text{water}} (h_w)

𝛾𝑤𝑎𝑡𝑒𝑟 = Unit weight of water above the groundwater (lb/ft3)

ℎ𝑤 = Depth of the bore below groundwater elevation (ft)

Unit Weight of Soil Below Groundwater Elevation:

\gamma_w = \gamma_{\text{soil}} – \gamma_{\text{water}}

\gamma_w = \gamma_{\text{soil}} - \gamma_{\text{water}}

γsoil = Unit weight of soil above the groundwater (lb/ft3)

Radius of Plastic Zone:

R_{\text{pmax}} = \frac{h_{\text{total}}}{2}

R_{\text{pmax}} = h_{\text{total}}

htotal = Height of Ground Surface at Point of Interest (ft)

Effective Stress:

\sigma_0=\gamma_w\cdot h_{total}

\sigma_0=\gamma_w\cdot h_{total}Cavity Expansion Model

Maximum Allowable Mud Pressure:

P_{\text{max1}} = \mu +( \sigma_0(1 + \sin\varphi) + c.\cos\varphi +c.\cot\varphi)\left[ \left( \frac{R_0}{R_{\text{pmax}}} \right)^2 +\frac{\sigma_0.\sin\varphi + c.\cos\varphi} G\right]^{{ \frac{-\sin\varphi}{1+\sin\varphi}}} – c.\cot\varphi \~\P_{\text{max2}} = \mu + (\sigma_0(1 + \sin\varphi)) \left[ \left( \frac{R_0}{R_{\text{pmax}}} \right)^2 + \frac{ \sigma_0\sin\varphi}{G} \right] ^{{{\frac{-\sin\varphi}{1+\sin\varphi}}}}\~\ P_{\text{max3}} = \mu + \sigma_0 + c

P_{\text{max1}} = \mu +( \sigma_0(1 + \sin\varphi) + c.\cos\varphi +c.\cot\varphi)\left[ \left( \frac{R_0}{R_{\text{pmax}}} \right)^2 +\frac{\sigma_0.\sin\varphi + c.\cos\varphi} G\right]^{{ \frac{-\sin\varphi}{1+\sin\varphi}}} - c.\cot\varphi \\~\\P_{\text{max2}} = \mu + (\sigma_0(1 + \sin\varphi)) \left[ \left( \frac{R_0}{R_{\text{pmax}}} \right)^2 + \frac{ \sigma_0\sin\varphi}{G} \right] ^{{{\frac{-\sin\varphi}{1+\sin\varphi}}}}\\~\\ P_{\text{max3}} = \mu + \sigma_0 + c

φ = Soil friction angle (degree)

R0 = Borehole radius (inch)

C =Cohesion coefficient (lb/ft2)

G = Shear modulus of soil (lb/ft2)

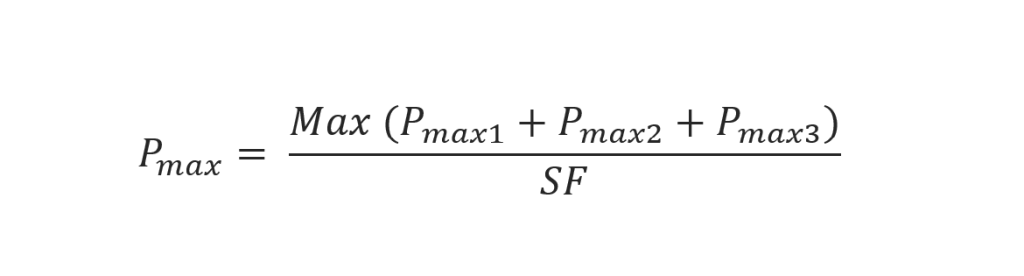

Pmax with Safety Factor (SF)

Minimum Required Mud Pressure:

v := \frac{Q}{0.785(\text{bore}{diameter} – d{\text{pipe}})^2}\~\P_{\text{min}} = \gamma_{\text{mud}}.h_{\text{total}} + L_{\text{bore}} \left{ \left[ \frac{\mu_{p1}.v}{(\text{bore}{diameter} – d{\text{pipe}})^2} \right] + \left[ \frac{\tau_y}{\text{bore}{diameter} – d{\text{pipe}}} \right] \right}

v = \frac{Q}{2.448(\text{bore}_{diameter}^2 - d_{\text{pipe}}^2)}\\~\\P_{\text{min}} = \gamma_{\text{mud}}.h_{\text{total}} + L_{\text{bore}} \left\{ \left[ \frac{\mu_{p1}.v}{(\text{bore}_{diameter} - d_{\text{pipe}})^2} \right] + \left[ \frac{\tau_y}{\text{bore}_{diameter} - d_{\text{pipe}}} \right] \right\}

ϒmud = Unit weight of drilling fluid (lb/gal)

Lbore = Distance from the rig entry point (ft)

borediameter = Borehole diameter (inch)

dpipe = Drill or pipe product outside diameter (inch)

µp1 = Viscosity of drilling fluid (cP)

τy = Yield point of drilling fluid (lb/100ft2

Average Soil Layer Model

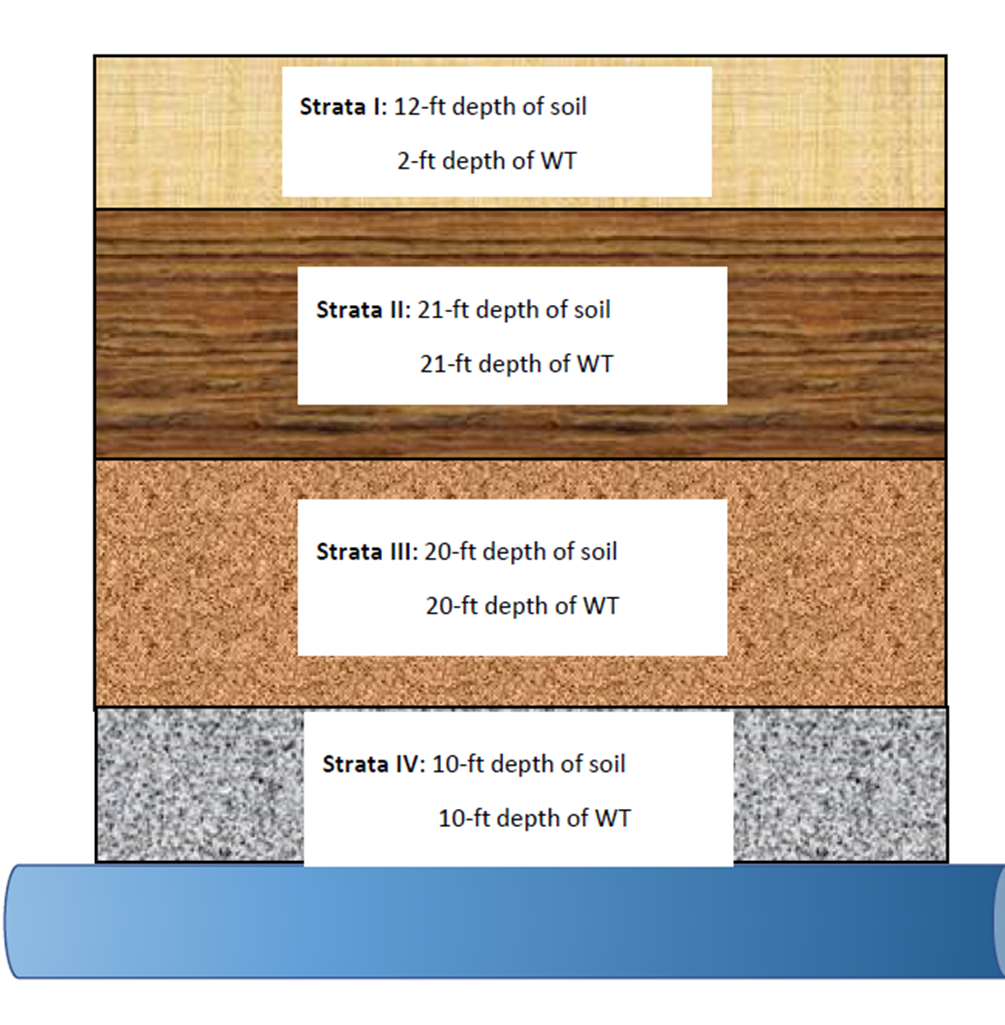

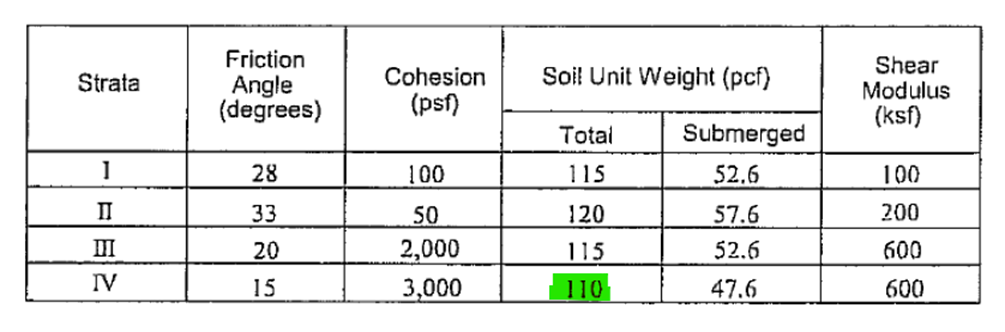

The Average Soil layer model is also called as the Average Delfts model and is useful in evaluating the stress induced in the bore profile due to different layers of soil materials.

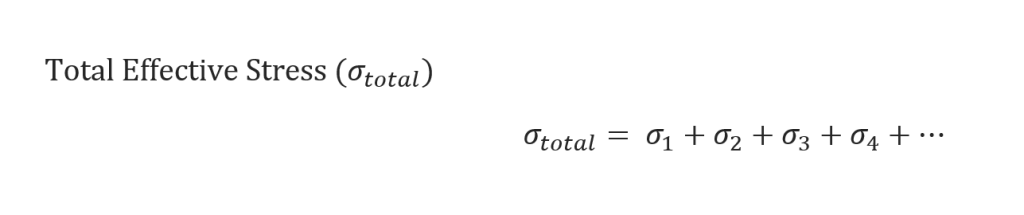

In this situation calculate the initial effective stress (σo) for each soil layer and add them together to get the initial effective stress at the point of interest.

There are 3 variations of the model available in HDD PowerTool

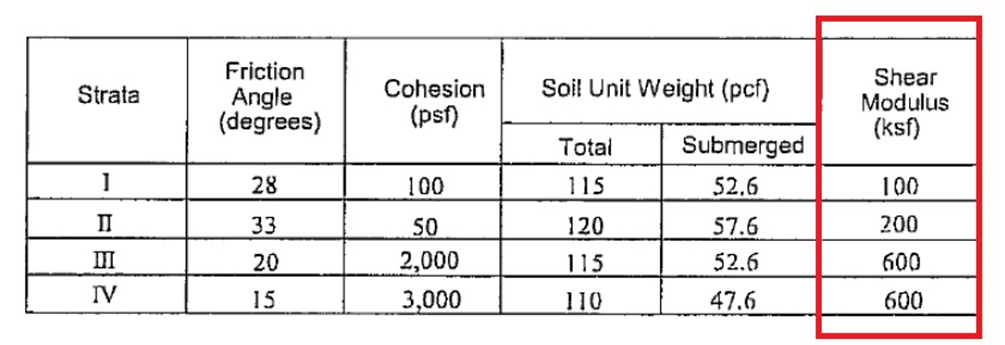

Contact Layer

This approach use the soil weight of the layer of soil around the borehole as this will have the greatest influence since the pressures are highest near the bore in calculating the total effective stress.

Here strata IV is closest to the bore profile and hence soil weight of the highlighted layer will be used to calculate total effective stress.

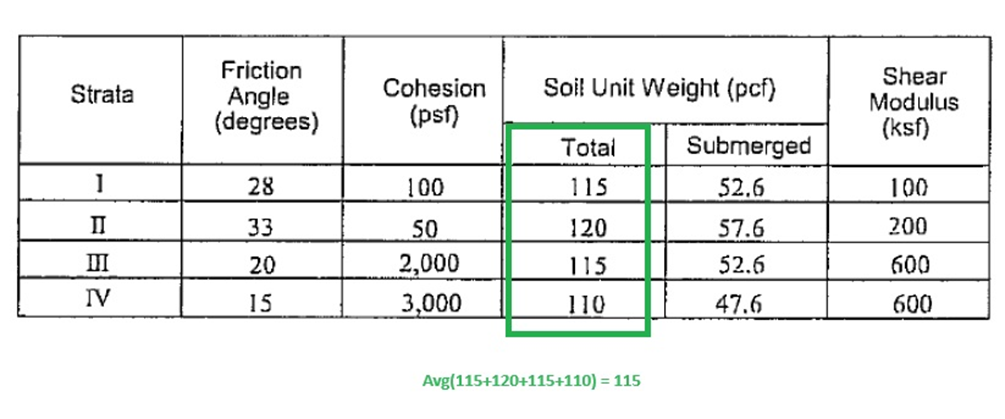

Average Soil Weight

In this approach the effective stress is evaluated using the average soil weight of the individual soil layers. Once effective stress of each layer is calculated they are added to obtain the total effective stress (σo).

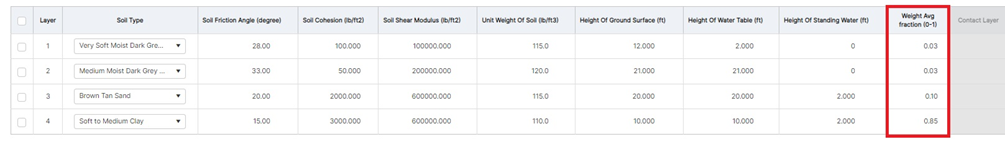

Weighted Average

The soil friction angle, cohesion, and shear modulus can also change with the various soil conditions. The values for these variables can be used as a weighted average in this approach to provide a convenient and provide conservative results.

In the example approach below to calculate shear modulus, we assume the layer of soil around the borehole will have the greatest influence since the pressures are highest near the bore. So we have weighted the layer at 85% (0.85) and the rest of the layer accordingly.

The same approach can be applied for all the soil properties (soil friction angle, cohesion, soil weight and shear modulus) in the Average Soil Layer model.

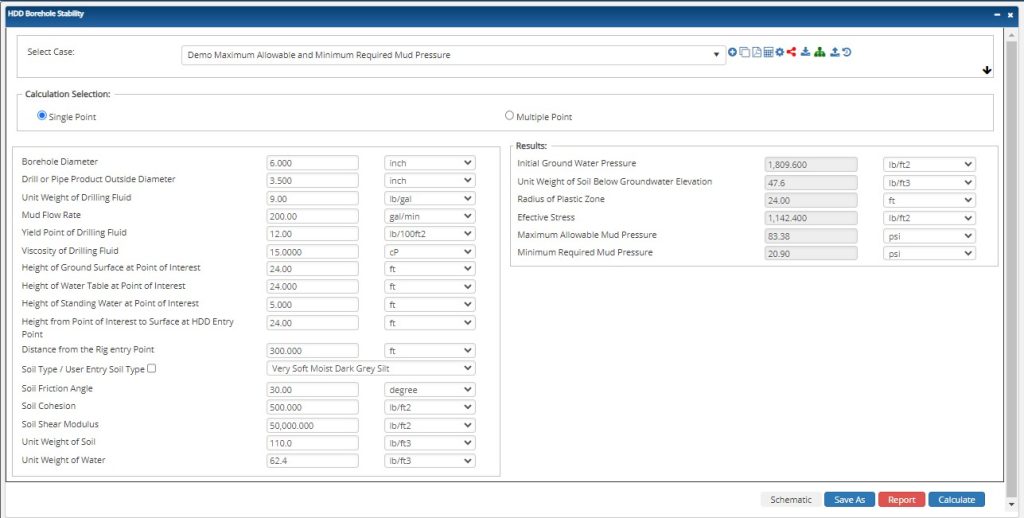

Input Parameters (Single Point)

- Borehole Diameter [inch]

- Drill or Pipe Product Outside Diameter [inch]

- Unit Weight of Drilling Fluid [lb/gal]

- Mud Flow Rate [gal/min]

- Yield Point of Drilling Fluid [lb/100ft2]

- Viscosity Drilling Fluid [cP]

- Height of Ground Surface at Point of Interest [ft]

- Height of Water Table at Point of Interest [ft]

- Height of Standing Water at Point of Interest [ft]

- Height from Point of Interest to Surface at HDD Entry Point [ft]

- Distance from the entry Point [ft]

- Soil Type

- Soil Friction Angle [degree]

- Soil Cohesion [lb/ft2]

- Soil Shear Modulus [lb/ft2]

- Unit Weight of Soil [lb/ft3]

- Unit Weight of Water [lb/ft3]

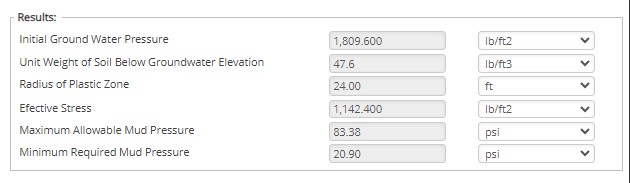

Outputs/Reports (Single Point)

- Initial Ground Water Pressure [lb/ft2]

- Unit Weight of Soil Below Groundwater Elevation [ [lb/ft3]

- Radius of Plastic Zone [ft]

- Effective Stress [lb/ft2]

- Maximum Allowable Mud Pressure [psi]

- Minimum Allowable Mud Pressure (HDD Consortium) [psi]

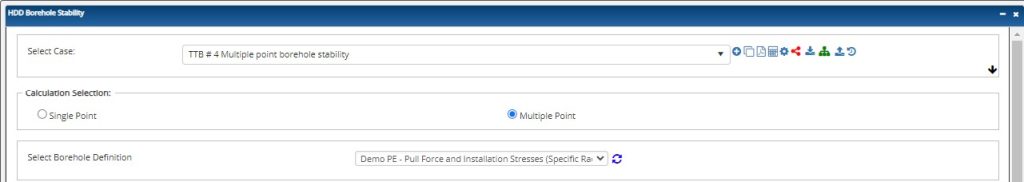

Input Parameters (Multiple Point)

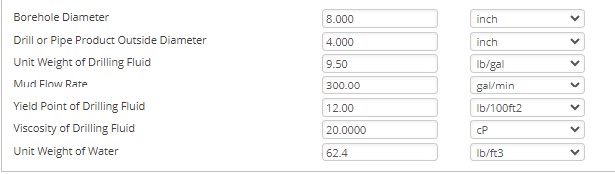

- Borehole Diameter [inch]

- Drill or Pipe Product Outside Diameter [inch]

- Unit Weight of Drilling Fluid [lb/gal]

- Mud Flow Rate [gal/min]

- Yield Point of Drilling Fluid [lb/100ft2]

- Viscosity Drilling Fluid [cP]

- Unit Weight of Water [lb/ft3]

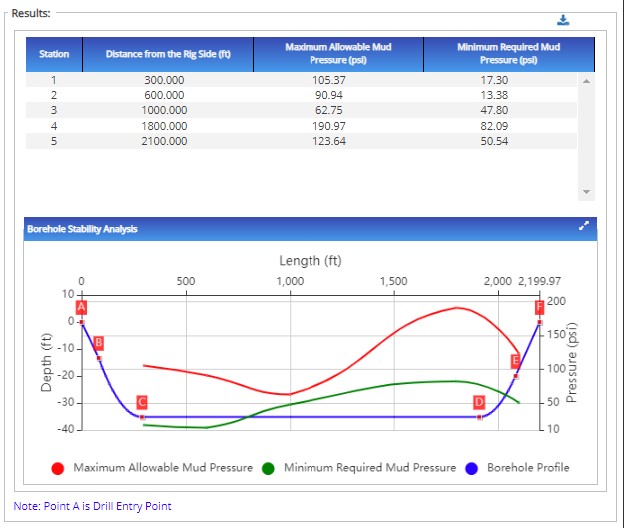

Outputs/Reports (Multiple Point)

- Station

- Distance from the Rig Site

- Maximum Allowable Mud Pressure

- Minimum Required Mud Pressure

- Borehole Stability Analysis

- Plot/Graph

- Expanded Version

References

- Willoughby, David (2005). Horizontal Directional Drilling, McGraw-Hill, New York, ISBN 0-87814-395-5. v.

- Willoughby, David, Training – Horizontal Directional Drilling, TTI, November 2016

- HDD Consortium. (2001). Horizontal directional drilling, good practices guidelines, HDD Consortium.

- Horizontal Directional Drilling Training Manual, Horizontal Drilling International, February 1999

- Skonberg, Eric R. II. Muindi, Tennyson M. (2014). Pipeline Design for Installation by Horizontal Directional Drilling, American Society of Civil Engineers. Horizontal Directional Drilling Design Guideline Task Committee.

- “Installation of Pipelines by Horizontal Directional Drilling”, PRCI Report PR-227-9424

- Nayyar, Mohinder L. (1992). Piping Handbook, 6th Edition, McGraw-Hill, New York, NY.

- AWWA (2006), PE Pipe Design and Installation, M55, American Water Works Association, Denver, CO

- ASTM (1962), PPI Handbook

AUGER BORING – Casing is jacked into the ground as a rotating auger works simultaneously to remove the excavated soil. It is commonly used in applications where settlement is a concern: under highways, railways and levies. Also known as a dry bore.

BENTONITE – A natural clay material used as a basic ingredient for drilling muds and lubricants to facilitate ease of installation.

BORE OR BOREHOLE – drilling term – The elongated cavity created by the drilling process. Often the borehole is not a void, but rather a hole filled with drilling mud and cuttings. Well casing is pulled or pushed into the borehole to complete a well.

CASING – drilling term – The non-perforated or non-slotted pipe that comprises the entry and exit sections of a horizontal well, as opposed to the well screen. Surface casing is a pipe that is set through loose surficial deposits to stabilize the bore, so the deeper sections can be drilled without difficulty from caving or collapse in the upper section of the borehole.

CROSSING – A pipeline installation designed to pass beneath a surface obstruction. Examples of crossings include roads, railway tracks, water bodies, pipeline corridors, and utilities.

DRILLING MUD – drilling material – aqueous slurry that is used during drilling to transport drill cuttings from the borehole, prevent borehole collapse and provide lubrication for the drill string. Most horizontal drilling uses drilling mud of some sort, although in some conditions it is possible or preferable to drill using air or water. Drilling mud made be made using the mineral bentonite, synthetic or natural polymers, or some combination of the two.

DRILL RIG – A trenchless machine that installs pipes and cables by drilling a pilot hole that can be enlarged (if necessary), and then pulling the product line.

ENTRY POINT – The starting location of the crossing where the drill enters the ground.

EXIT POINT – The end location of the crossing.

FORWARD REAMER – drilling tool – A type of reamer used to enlarge the diameter of the borehole in a blind or single-entry well.

HORIZONTAL DIRECTIONAL DRILLING (HDD) – A surface-based trenchless technology that involves a horizontal bore under the surface along a planned pathway. Once the HDD creates a bore of a suitable size – which may require one or multiple passes by the drilling apparatus – the conduit or pipe is pulled into the bore and connections are made to the appropriate utilities.

OPEN CUT – Underground construction method involving excavation from ground level to the level required for the installation, maintenance, or inspection of a pipe, conduit, or cable. Upon completion of the work, the trench is backfilled, and the surface restored. Backhoe excavation is an example of open-cut construction.

PILOT BORE – drilling term – The initial boring made in a horizontal well installation. The pilot bore is steered, using any of several technologies, from a designated entry point, along a predetermined bore path, to a designated endpoint, either at the ground surface or at depth. The pilot bore subsequently may be reamed to a larger diameter to accommodate the desired size well screen and casing.

PIPE PULLING – Method used to replace small diameter pipes by attaching new product pipe to the existing pipe, which is then pulled out of the ground.

POTHOLE – drilling term – a small hole excavated from the surface to a buried utility in order to provide positive verification of its location.

REAMER – drilling tool – a cutting tool used to enlarge the diameter of a borehole after the pilot bore has been drilled.

FAQ

-

HDD Power Tool?

Horizontal Directional Drilling or HDD, is a method of installing steel or polyethylene pipe, conduit, or cables in a designed bore path, by using a drilling rig, with a minimal footprint to the environment. HDD process represents a significant improvement over traditional open cut and disturbance methods for installing pipelines beneath obstructions, such as rivers or roads, which require specialized construction attention. To take full advantage of the benefits offered by horizontal directional drilling and produce designs which can be efficiently executed in the field, design engineers need a working knowledge of the process with the appropriate HDD software. Check Out

-

HDD – Version Capability Matrix

Calculations and functions involving the capabilities that HDD can provide. Check Out

-

HDDPT Process to Import KML/KMZ and Shape Files?

Here relies the step-by-step procedure of importing files and having them project accurate calculations to your reports. Check Out

-

How to Calculate a Compound Angle?

The HDD PowerTool program will calculate the compound data based on the horizontal and vertical data you enter.

For example: In the below screenshot, under curve, select the compound. You may then input 2 data elements for the horizontal and vertical part of the bend. The program will then calculate the compound. Check Out

-

Update on the Latest Technical Capabilities of the HDDPT?

Steel cased crossings have been used to avoid load considerations, unstable soil conditions, third party mechanical damage or when conditions dictated by regulatory or sound engineering practices. However, due to a variety of factors such design, installation, construction practices, materials, coatings, etc. have caused problems with protecting the carrier pipe within the casing. Check Out

-

Combined Stresses and Limitations for Both Liquid & Gas HDD?

HDD combined stresses can be analyzed by calculating the maximum shear stress on a small element in the pipeline. Maximum shear stress should be limited to 45% of the SMYS of the pipe (ASME/ANSI B31.4). This is in accordance to PRCI report PR-227-9424 from the findings and conclusions of those companies who performed and approved the research work, However, the question comes up from time to time that the B31.4 code can be converted to B31.8’s code application. Check Out

-

Hydraulic Fracture Analysis Geological Layers Data Input?

Some typical values of soil friction angle are given below for different USCS soil types at normally consolidated condition unless otherwise stated. These values should be used only as guideline for geotechnical problems; however, specific condition of each engineering problem often needs to be considered for an appropriate choice of geotechnical parameters. Check Out