Introduction

This application is related bending stresses and deflection on a uniformly loaded span. The weight of the pipe and product.

If there is more than one loading, superimposing individual solutions will be required. To account for unknown stresses multiply the longitudinal stress by 1.1.

Fixed End Supports:

y=\frac{7.6WL^4}{E(D^4-d^4)}\~\S=\frac{10.2WL^2}{(D^4-d^4)}

y=\frac{7.6WL^4}{E(D^4-d^4)}\\~\\S=\frac{10.2WL^2}{(D^4-d^4)}Where:

𝑦 − Maximum Deflection (ft)

𝑆 − Maximum Bending Stress (psi)

𝑊 − Unit Weight (lbf)

𝐿 − Length (ft)

𝐸 − Modulus of Elasticity (psi)

(𝑆𝑡𝑒𝑒𝑙 = 30,000,000, 𝑝𝑙𝑎𝑠𝑡𝑖𝑐 (𝑑𝑢𝑝𝑜𝑛𝑡) = 100,000, 𝑝𝑙𝑎𝑠𝑡𝑖𝑐 (𝑝𝑙𝑒𝑥𝑐𝑜) = 125,000, 𝑐𝑎𝑠𝑡 𝑖𝑟𝑜𝑛 = 15,000,000, 𝑐𝑜𝑝𝑝𝑒𝑟 = 15,000,000)

𝐷 − Outside Diameter (in)

𝑑 − Inside Diameter (in)

Simple Supports:

𝑦 = 5 times 𝑦 for fixed ends

𝑆 = 1.5 times 𝑆 for fixed ends

Cantilever Supports:

𝑦 = 48 times 𝑦 for fixed ends

𝑆 = 6 times 𝑆 for fixed ends

𝑆 and 𝑦 on the schematics indicate the points of MAXIMUM stress deflection.

Case Guide

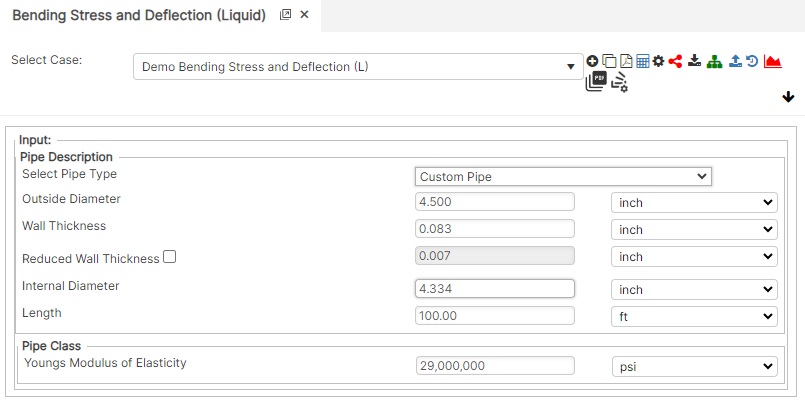

Part 1: Create Case

- Select the Bending Stress and Deflection application from the Design & Stress Analysis Module

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required Parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

Input Parameters

- Nominal Pipe Size (in):(0.625” – 48”)

- Wall Thickness (in):(0.068”- >2”)

- Pipe grade: (24000psi-80000psi) (if unknown use Grade A 24000)

- Pipe Length (ft)

- Youngs Modulus of Elasticity (psi)

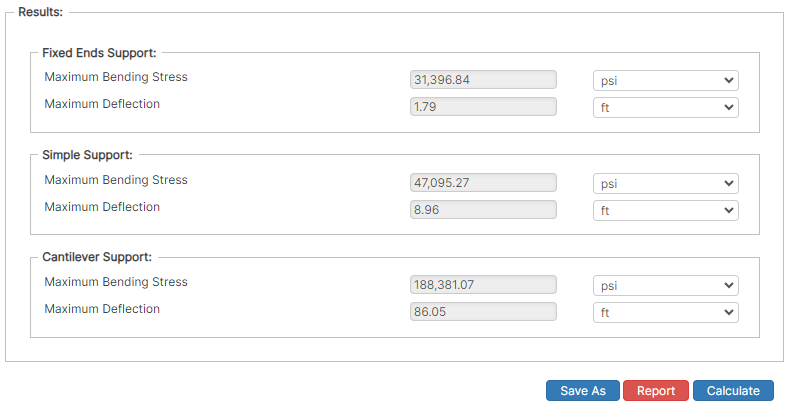

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

Results

- Fixed End Supports/ Simple Supports/Cantilever Supports

- Maximum Bending Stress (psi)

- Maximum Deflection (ft)

References

- ASME B31.8 – Gas Transmission and Distribution Piping Systems

- API 5L, API 5LS and API 5LX – Specification of Pipe Grade

- ASTM – Various – Weld Joint Factor

- CFR Code Part 192

- MMS Regulations

- USDA-SCS Modified (Permissible Velocity of Water and Soil Erodibility)

- FHWA-HEC

- Pipeline Rules of Thumb Handbook

FAQ

-

Restrained versus Unrestrained Pipe (Difference in Gas vs. Liquid)?

ASME B31.4 liquid and B31.8 gas codes include calculations for the net longitudinal compressive stress that must be applied only for a restrained line that equates to a low (less than 2%) longitudinal strain. This stress status is characteristic to underground pipelines located some distance away from above ground piping facilities.

Unrestrained lines means those above ground sections of piping without axial restraint as with buried pipe with soil. In others words the soil exerts substantial axial restraint, but not fully restrained. Check Out

-

What is the Maximum Span Length of rev1?

Regarding span factors with and without water are based on bending stress and deflection. Larger diameter pipe spans require saddles for stability. Many standards that require pipes to be filled with water are based on bending and shear stresses not to exceed 1,500 psi and a deflection between supports not exceed 0.1 inches. Check Out

-

What is the model used for Thrust at Blow-Off?