Restrained pipes are typically buried with proper bedding. However, when settlement or subsidence occurs the longitudinal and combined stresses may be replaced with a strain limit of 2% in ASME B31.4

Yielding that does not impair the serviceability of the pipe. Local stresses caused by periodic or repetitive load resulting in fatigue. Unanticipated earthquakes vibration and thermal expansion.

𝑆𝐻 − Hoop stress(psi)

𝑃 − Pipe internal pressure(psi)

𝐷 − Pipe outside diameter(in)

𝑡 − Pipe wall thickness(in)

Hoop Stress

𝑃 − Pipe internal pressure(psi)

𝐷 − Pipe outside diameter(in)

𝑡 − Pipe wall thickness(in)

Longitudinal Stress due to Internal Pressure

𝑆𝑃 = 0.3𝑆𝐻

𝑆𝑃 − Longitudinal stress due to internal pressure(psi)

𝑆𝐻 − Hoop stress(psi)

Longitudinal Stress due to Thermal Expansion

𝑆𝑇 = 𝐸𝛼(𝑇1−𝑇2)

𝑆𝑇 − Longitudinal stress due to thermal expansion(psi)

𝛼 − Coefficient of thermal expansion(1/℉)

𝐸 − Elastic modulus of ambient temperature(psi)

𝑇1 − Pipe Temperature at the time of instalation(℉)

𝑇2 − The warmest or coldest pipe operating temperature(℉)

Nominal Bending Stress

𝑆𝐵 − Nominal bending stress(lb/in)

𝑀 − Calculated bending moment

𝑍 − Pipe section modulus(in3)

Stress due to Axial Loading

𝑆𝑋 −Axial loading stress(lb/in)

𝑅 −External for axial component(lb)

𝐴 −Pipe metal cross sectional area(in2)

Net Longitudinal Stresses

𝑆𝐿 − Net longitudinal stress in restrained pipe(psi)

Note: The maximum permitted value for is 0.9ST

𝑆 − Specified minimum yield strength(psi)

𝑇 − Temperature derating factor

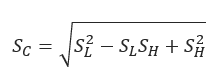

Combined Biaxial Stress

𝑆𝐶 −Combined biaxial stress(psi)

Note: The maximum permitted value of 𝑆𝐶. is 𝑘𝑆𝑇

𝑘 ≤ 0.9−for load of long duration

𝐾 = 1.0−for occasional nonperiodic loads of short duration

𝑆 − Specified minimum yield strength(psi)

𝑇 − Temperature derating factor

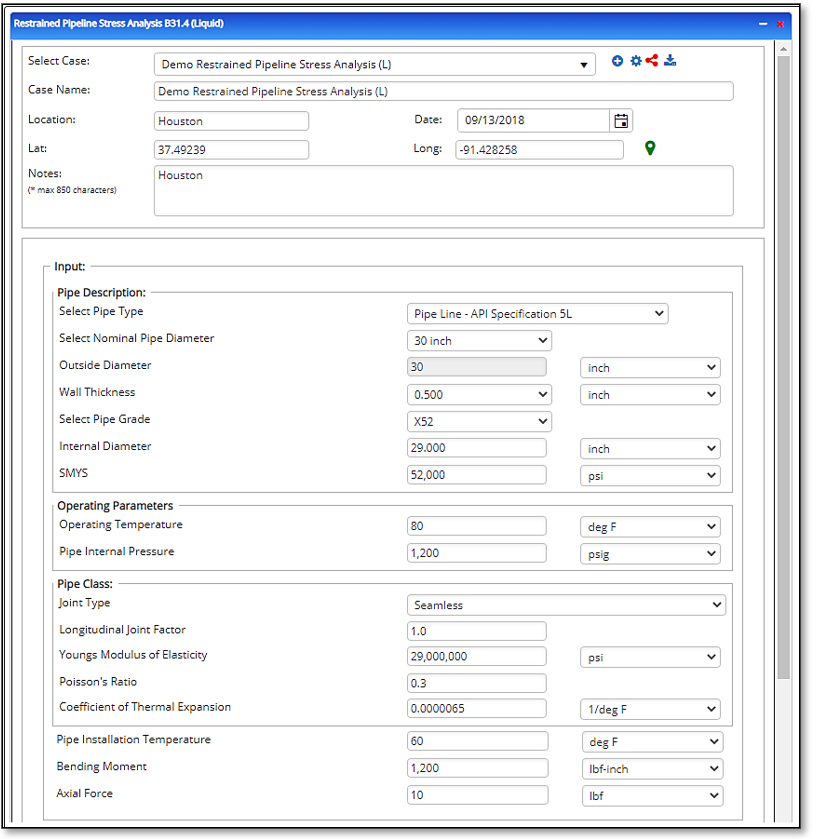

Input Parameters

- Select the Restrained Pipeline Stress Analysis application from the Steel Pipe – Design and Stress Analysis module.

- To create a new case, click the “+” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button.

- Nominal Pipe Size(in)

- Wall Thickness(in)

- Pipe grade (if unknown, use Grade A 24000)

- T – Temperature Derating Factor

- Pipe Internal Pressure

- Pipe Installation Temp

- Pipe Operating Temp

- Nominal Bending Stress(psi)

- Stress due to Axial Load(psi)

- k – Load Factor while providing Poisson’s Ratio

- Young’s Modulus of Elasticity

- Thermal Expansion Coefficient(1/°F)

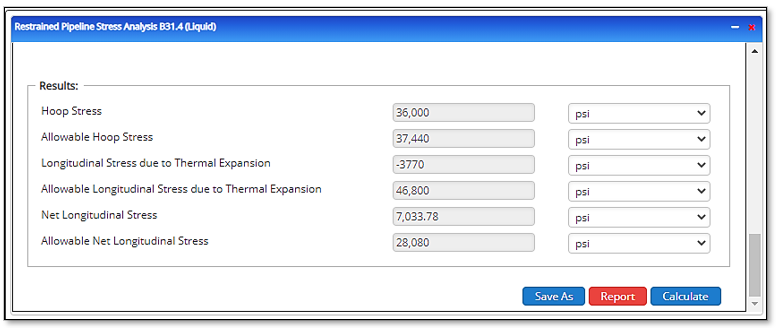

Outputs/Reports

- View the results.

- If an input parameter needs to be edited be sure to hit the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon.

- To delete a case, click the DELETE icon near the top of the widget.

- Hoop Stress(psi)

- Longitudinal Stress due to Internal Pressure(psi)

- Longitudinal Stress due to Thermal Expansion(psi)

- Net Longitudinal Stress(psi)

- Maximum Permitted Longitudinal Stress(psi)

- Combined Biaxial Stress(psi)

- Maximum Permitted Combined Biaxial Stress(psi).