Design Pressure Polyethylene Pipe

Polyethylene Line Pipe is designed in accordance to API 15LE based on material designation of specified pipe size and wall thickness, standard dimension ratio, temperature and design factor i.e. 0.32.

Limitations include pressure in distribution and class 3/4 areas, temperatures below -20 degrees and above 150 F, wall thickness, and certain type of materials.

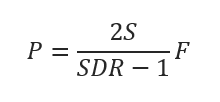

Where:

𝑃 = Internal Pressure ,psi.

𝑆 = Hydrostatic Design Basis, [psi](1600 for polyethylene pipe)

𝑆𝐷𝑅 = Standard Dimension Ratio ,D/t.

𝐷 = Outside Diameter ,in.

𝑡 = Minimum Wall Thickness ,in.

𝐹 = Design Safety Factor (0.5 for water @ 73℉)

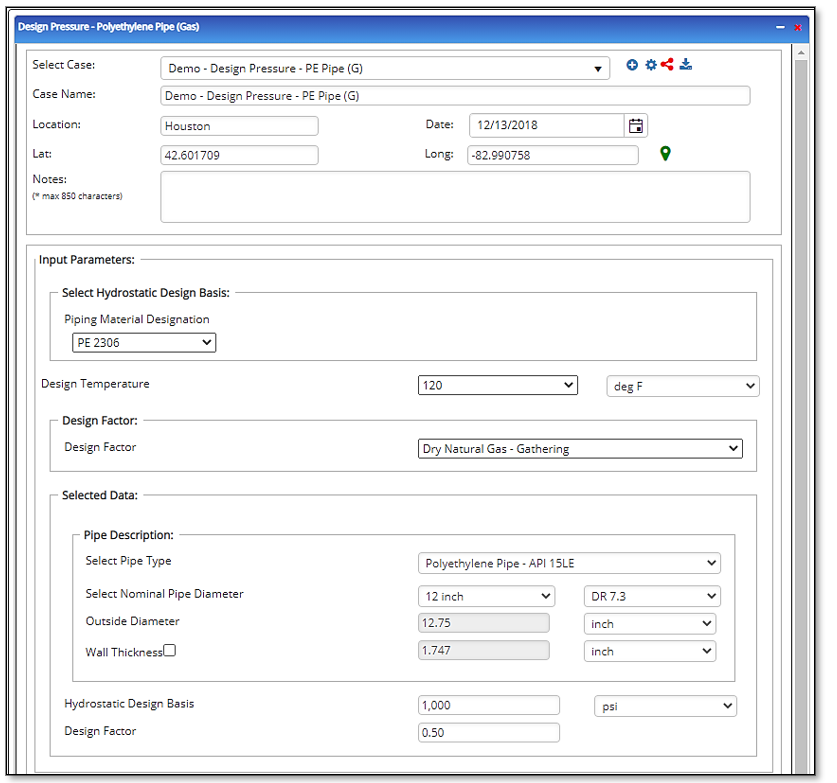

Input Parameters

- To create a new case, click the “Add Case” button

- Select the Design Pressure – Polyethylene Pipe application from the Polyethylene Pipe – Design & Stress Analysis module list.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button

· Pipe Material Designation

· Design Temperature

· Design Factor

· Nominal Pipe Size

· Nominal Outside Diameter

· Nominal Wall Thickness

· Hydrostatic Design Basis

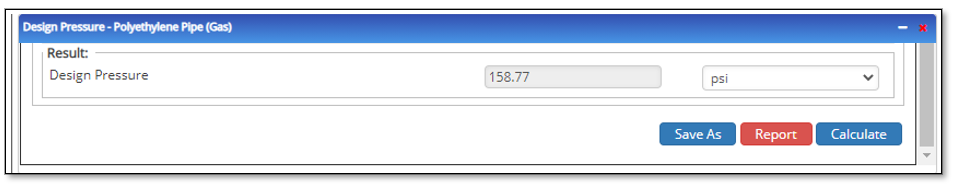

Outputs/Reports

1. View the results.2. If an input parameter needs to be edited be sure to hit the CALCULATE button after the change.

3. To SAVE, fill out all required case details then click the SAVE button.

4. To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

5. To generate a REPORT, click the REPORT button.

6. The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon.

7. To delete a case, click the DELETE icon near the top of the widget.

· Internal Design Pressure