Introduction

The ASME Code requires that capacity certification be obtained for PRVs designed for liquid service. The procedure for obtaining capacity certification includes testing to determine the rated coefficient of discharge for the liquid PRVs at 10 % overpressure. The sizing equations for pressure-relief devices in liquid service provided in this section assume that the liquid is incompressible (i.e. the density of the liquid does not change as the pressure decreases from the relieving pressure to the total backpressure).

A = \frac{Q}{38 K_d K_w K_c K_v} \sqrt{\frac{G_1}{P_1 – P_2}}

A = \frac{Q}{38 K_d K_w K_c K_v} \sqrt{\frac{G_1}{P_1 - P_2}}Where:

𝐴 − the required effective discharge area (in2)

𝑄 − the flow rate (gal/min)

𝐾𝑑 − the rated coefficient of discharge

𝐾𝑤 − correction factor due to backpressure

- If the backpressure is atmospheric, use a value for Kw of 1.0. Balanced bellows valves in backpressure service will require the correction factor determined from Figure 31. Conventional and pilot-operated valves require no special correction

𝐾𝑐 − combination correction factor for installations with a rupture disk upstream of the PRV

- 1.0, when a rupture disk is not installed;

- 0.9, when a rupture disk is installed in combination with a PRV and the combination does not have a certified value;

𝐾𝑣 − correction factor due to viscosity

K_v = \left(0.9935 + \frac{2.878}{Re^{0.5}} + \frac{342.75}{Re^{1.5}}\right)^{-1.0}

K_v = \left(0.9935 + \frac{2.878}{Re^{0.5}} + \frac{342.75}{Re^{1.5}}\right)^{-1.0}

Where:

𝐺1 − the specific gravity of the liquid at the flowing temperature referred to water at standard conditions

𝑃1 − upstream relieving pressure (psig)

𝑃2 − total backpressure (psig)

When a PRV is sized for viscous liquid service, it should first be sized as if it were for a non viscous type application (i.e. Kv = 1.0) so that a preliminary required discharge area, A, can be obtained from the equations above. From API 526 standard orifice sizes, the next orifice size larger than A should be used in determining the Reynold’s Number, Re, from either of the following relationships.

Re = \frac{Q(2800 \cdot G_1)}{\mu \sqrt{A}}

Re = \frac{Q(2800 \cdot G_1)}{\mu \sqrt{A}}

Where:

𝑅𝑒 − Reynolds Number

𝑄 − flow rate at the flowing temperature (gal/min)

𝐺1 − the specific gravity of the liquid at the flowing temperature referred to water at standard conditions

𝐴 − the required effective discharge area (in2)

Case Guide

Part 1: Create Case

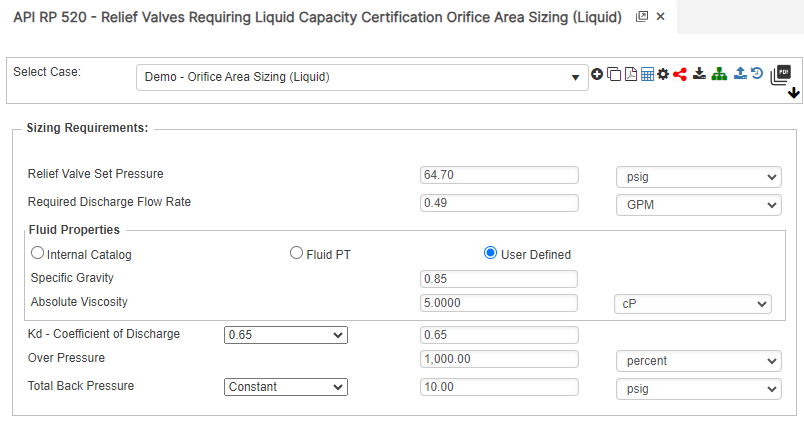

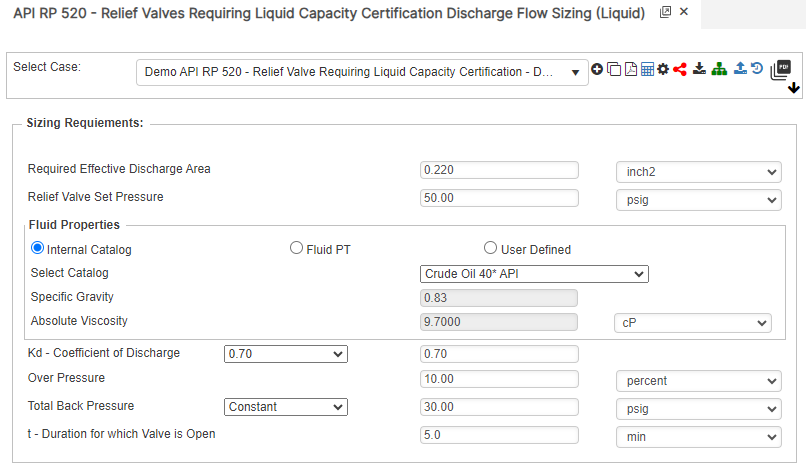

- Select the Relief Valves Requiring Capacity Certification application in the Facilities Module

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

Input Parameters

- Relief Valve Set Pressure (psig)

- Required Effective Discharge (GPM)

- Required Effective Discharge Area (in)

- Specific Gravity of Liquid

- Absolute Liquid Viscosity (cP)

- Kd- Coefficent of Discharge

- Overpressure (%)

- Total Back Pressure (psig)

- t – Duration for which Valve is Open (min)

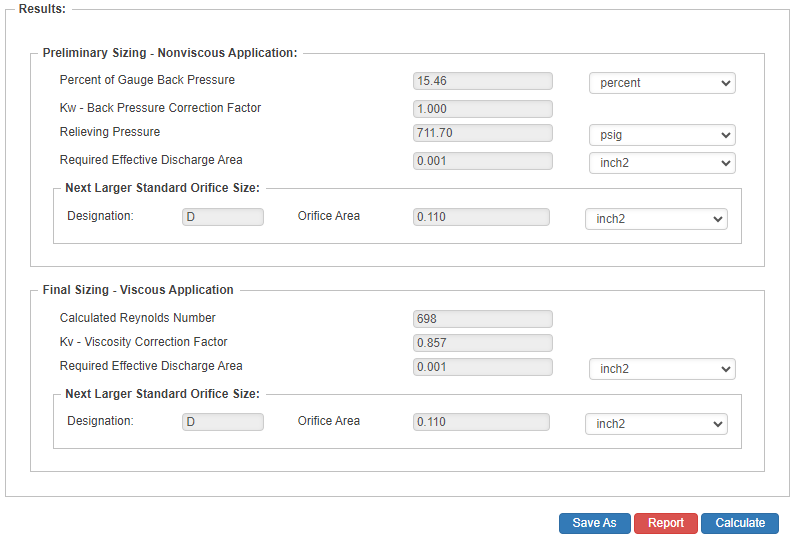

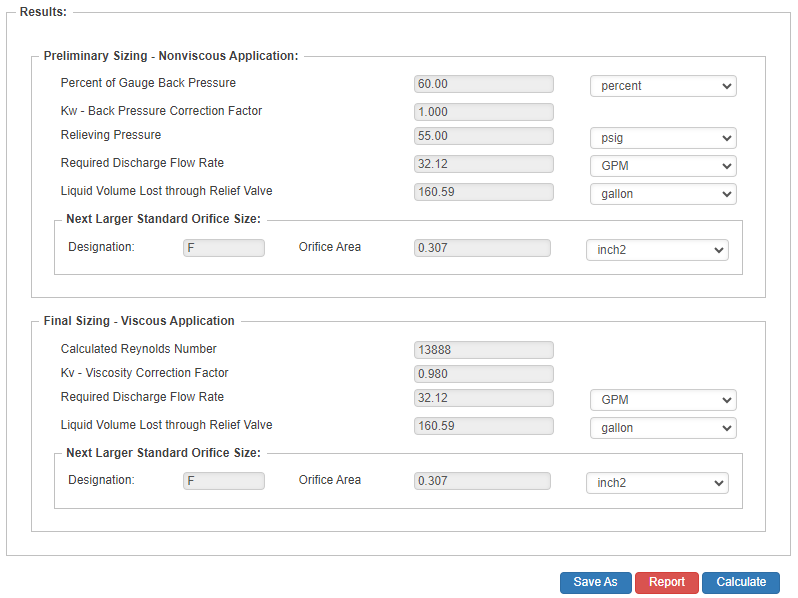

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

Non Viscous Results

- Percent of Gauge Back Pressure (%)

- Kw – Back pressure Correction Factor

- Relieving Pressure (psig)

- Required Discharge Flow Rate (gal/min)

- Next larger Standard Orifice Size

Viscous Results

- Calculated Reynolds Number

- Kv – Viscosity Correction Factor

- Required Discharge Flow Rate (gal/min)

- Next Larger Standard Orifice Size

References

- ASME – Boiler and Pressure Vessel Code, Section VIII

- API – RP 520 Part 2

- ASME B31.8 Gas Transmission and Distribution Piping Systems

- ASME B31.3, B31.4 and B31.8 – Full Encirclement Sleeves (See Appendices)

Appendix

Even though Technical Toolboxes does not provide software for a full-encirclement reinforcing saddles, many operators use them to provide reinforcement for branch outlets in accordance with ASME B31.3, B31.4, B31.8 and other applicable design codes. Full-encirclement reinforcing saddles are designed to fully encircle the run pipe however; they are not designed to be pressure retaining devices. To avoid gas entrapment during welding and to prevent pressure containment, should a leak develop underneath the saddles; these saddles should be provided with a vent to allow escaping product.

A typical field applied Full Encirclement Reinforcement Weldment Saddle is shown below:

FAQ

-

Validation check: Reinforcement of Welded Branch Connection?

This table highlights the list of validation checks that are in effect in the PLTB Gas > Pipeline Facilities> Reinforcement of Welded Branch Connection – ASME B31.8 calculation. Check Out

-

Orifice Coefficient for Hot Tap Sizing?

When a compressible fluid, such as natural gas or air, is passed through an orifice, the rate of flow is determined by the area of the orifice opening; the absolute upstream pressure is 𝑃1; and the absolute downstream pressure is 𝑃2: unless the ratio 𝑃2/𝑃1. equals or is less than the critical ratio. When 𝑃2/𝑃1 equals or is less than the critical ratio downstream pressure no longer effects rate of flow through the orifice, and flow velocity at the vene contracta is equal to the speed of sound in that fluid under that set of condition. This is commonly referred to as critical or sonic flow. Orifice equations are therefore classified as “sonic” or “subsonic” equations. Check Out

-

How is Required Area calculated for Branched Weld Connection?

The calculation is using the following is the equation that we use for A3 – REQUIRED AREA

A3 = Ar – A1-A’2

where:

Ar = Reinforcement Required

A1= Reinforcement Provided

A’2 = Corrected Effective Area