Introduction

Computation of A If the measured maximum depth of the corroded area is greater than 10 % of the nominal wall thickness, and the measured longitudinal extent of the corroded area is greater than the value determined by Equation (2), calculate: A=0.893\bigg(\frac{L_m}{\sqrt{{Dt}}}\bigg)

A=0.893\bigg(\frac{L_m}{\sqrt{{Dt}}}\bigg)

Where:

𝐴 − intermediate factor A

𝐿𝑚 − measured longitudinal extent of the corroded area(in)

𝐷 − nominal outside diameter of the pipe(in)

𝑡 − nominal wall thickness of the pipe(in)

Additional wall thickness required for concurrent external loads shall not be included in calculation.

Computation of P’

(a) For values of Less Than or Equal to 4.0.

P’ = 1.1P \left[ \frac{1 – \frac{2}{3} \left( \frac{d}{t} \right) }{1 – \frac{2}{3} \left( \frac{d}{t\sqrt{A^2 + 1}} \right)} \right]

P' = 1.1P \left[ \frac{1 - \frac{2}{3} \left( \frac{d}{t} \right) }{1 - \frac{2}{3} \left( \frac{d}{t\sqrt{A^2 + 1}} \right)} \right]

Where:

𝑃’− the safe maximum pressure for the corroded area

𝑑− measured maximum depth of corroded area(in)

𝐷− nominal outside diameter of the pipe(in). May not exceed P.

Ρ – the greater of either the established MAOP or

P=\frac{2S_tFT}{D}

P=\frac{2S_tFT}{D}Where:

𝑆− specified minimum yield strength (SMYS)(𝑝𝑠𝑖)

𝐹− appropriate design factor from ASME B31.4, ASMEB31.8, or ASME B31.11

𝑇− temperature derating factor from the appropriate B31 Code (if not listed, T = 1)

𝐷− nominal outside diameter of pipe(in)

𝑡 − nominal wall thickness of the pipe(in)

Additional wall thickness required for concurrent external loads shall not be included in the calculations.

(b) For Value of a Than 4.0.

P’=1.1P\bigg(1-\frac{d}{t}\bigg)

P'=1.1P\bigg(1-\frac{d}{t}\bigg)MAOP and P’

If the established MAOP is equal to or less than, the corroded region may be used for service at that MAOP. If the established MAOP is greater than, then a lower MAOP should be established not to exceed, or the corroded region should be repaired or replaced.

Case Guide

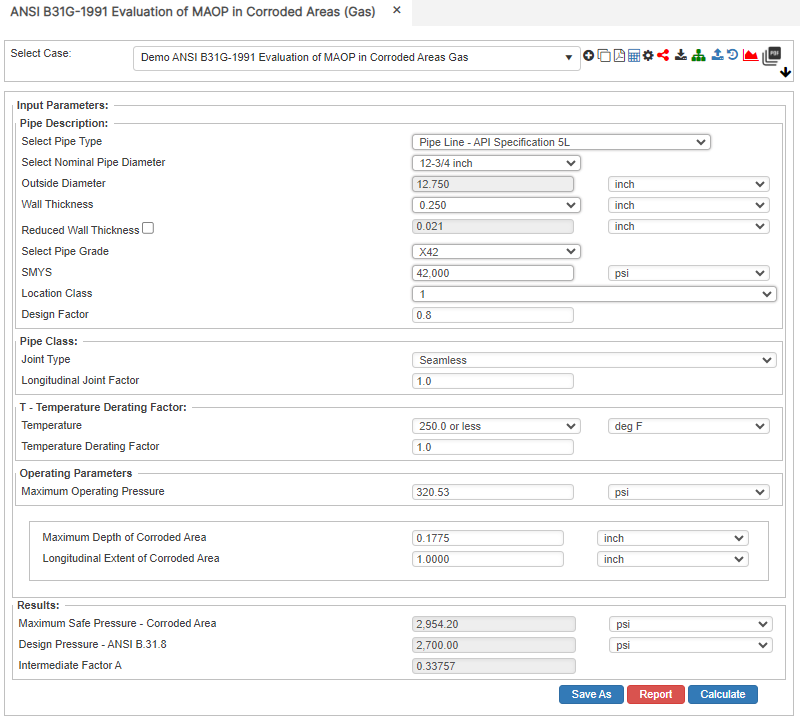

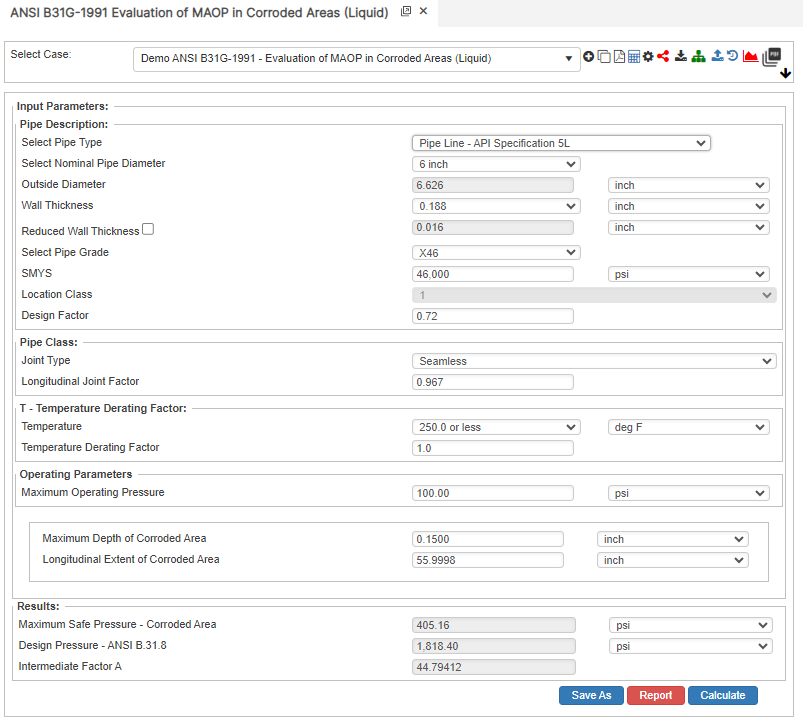

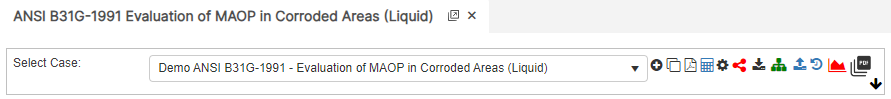

Part 1: Create Case

- Select the ANSI B31G-1991 Evaluation of MAOP in Corroded Areas application from the Pipeline Corrosion list.

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

Input Parameters

- Wall Thickness(in)

- Pipe Grade

- Design Factor – F

- Longitudinal Joint Factor – E

- Temperature Derating Factor – T

- Maximum Depth of Corroded Area

- Longitudinal Extent of Corroded Area

- Pipe Outside Diameter(in)

- Specified Minimum Yield Strength – SMYS

- Maximum Operating Pressure – MOP (psi)

Part 2: Outputs/Reports

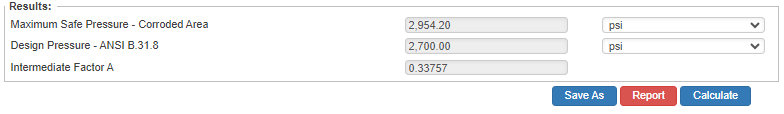

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

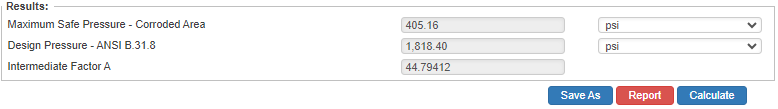

Results

- Maximum Safe Pressure(psi)

- Design Pressure – ANSI B.31.8(psi)

- Intermediate Factor A

References

- ANSI B31.G Calculations

- PRCI – A Modified Criterion for Evaluating the Remaining Strength of Corroded Pipe, Database for Corroded Pipe Tests and Continued Validation of RSTRENG

- NACE – Electrical Resistance and Resistivity Calculations

FAQ

-

ASME B31G Original/Modified and RSTRENG?

ASME B31.G Original and Modified (0.85) are Level 1 assessment along with most other metal loss calculations that are limited to pits and short lengths of pitting clusters. RSTRENG is a Level 2 metal loss calculation; however, it is not limited just to pits, but most lengths of pitting i.e., 2500 mm (100 inches) using interaction rules that is not uncommon on some pipelines. Check Out

-

Preventative and Corrective Measures to Control Corrosion Pitting?

A corrosion rate needed to set the re-inspection interval, reassess the performance metrics and their current applicability, plus to ensure the assumptions made are correct. At each direct examination where corrosion pitting is found, the operator should measure and record each pitting cluster. Check Out

-

Estimating Internal Corrosion Rates?

Internal corrosion is most likely to occur where water first accumulates. Predicting these locations of water accumulation serve as a method for prioritizing local examinations. Predicting where water first accumulates requires knowledge about the multiphase flow behavior in the pipe requiring certain data. Check Out

-

Estimating External Corrosion Rates?

All corrosion defects found during each direct examination should be measured, documented, and remediated as needed. At each excavation, the pipeline operator should measure and record generic environmental characteristics (such as soil resistivity, hydrology, drainage etc.). Check Out