Introduction

This application uses gas velocity and flow rates to determine the minimum required pipe diameter for station piping.

Gas Velocity

v=\frac{127.3\times10^3QP_bT_fZ}{D^2P_fT_b}

v=\frac{127.3\times10^3QP_bT_fZ}{D^2P_fT_b}Pipe Diameter

D=\sqrt{\frac{127.3\times10^3QP_bT_fZ}{vP_fT_b}}

D=\sqrt{\frac{127.3\times10^3QP_bT_fZ}{vP_fT_b}}Wall Thickness

Wt=\frac{P\left( \frac{127.3\times10^3QP_bT_fZ}{vP_fT_b} \right)^{0.5}}{2S}FET

Wt=\frac{P\left( \frac{127.3\times10^3QP_bT_fZ}{vP_fT_b} \right)^{0.5}}{2S}FETWhere:

𝑣 − Gas Velocity (ft/min)

𝑄 − Flow Rate (MMCFD)

𝑊𝑡 − Wall Thickness (in)

𝑃 − Design Pressure (psi)

𝐹 − Design Factor

𝐸 − Longitudinal Joint Factor

𝑇 − Temperature Derating Factor

𝑃𝑏 − Base Pressure (psia)

𝑇𝑓 − Flowing Temperature (°R)

𝑍 − Compressibility Factor

𝐷 − Internal Pipe Diameter (in)

𝑃𝑓 − Flowing Pressure (psia)

𝑇𝑏 − Base Temperature (°R)

Note: Gas velocity in piping should not exceed 2000(ft/min)

CNGA/GPSA Compressibility Factor Approximation:

Z=\frac{1}{\left[1+\left(\frac{3.444\times10^5P\times10^{1.785G}}{T_f^{3.825}} \right)\right]}

Z=\frac{1}{\left[1+\left(\frac{3.444\times10^5P\times10^{1.785G}}{T_f^{3.825}} \right)\right]}Where:

𝑍 − Compressibility Factor

𝑃 − Pressure

𝑇𝑓 − Gas Flowing Temperature (°𝑅)

This approximation will produce results sufficiently accurate for preliminary calculations.

Brake Horsepower

BHP=\frac{HP}{n_m}

BHP=\frac{HP}{n_m}Where:

𝑛𝑚 − Mechanical Efficiency 𝑛𝑚 = 0.95/0.98

Case Guide

Part 1: Create Case

- Select the Compressor Station Piping application from the Compressor Module

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required Parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

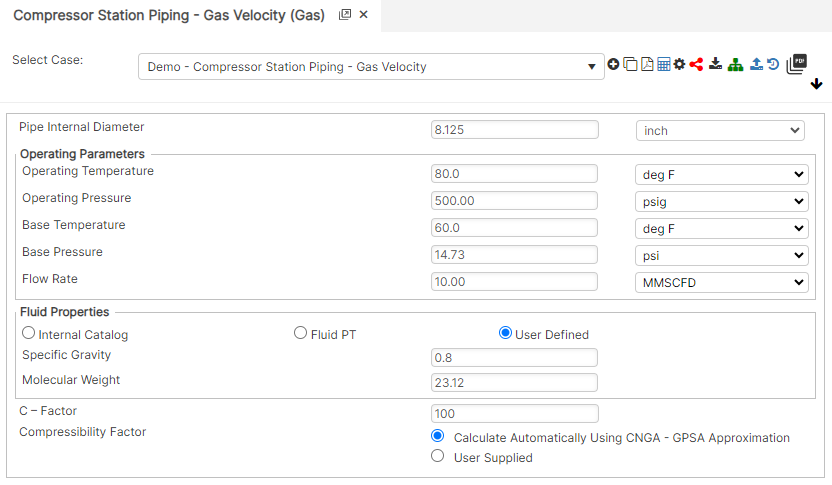

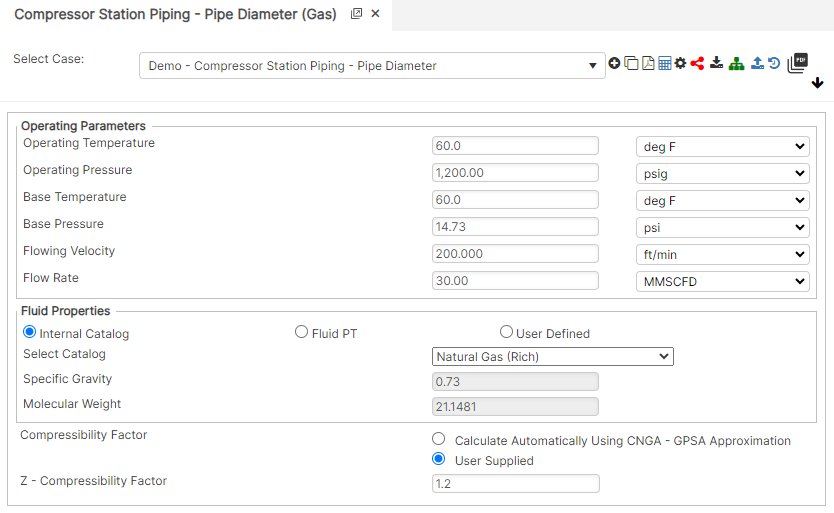

Input Parameters

- Pipe Internal Diameter (in)

- Operating Temperature (°F)

- Operating Pressure (psig)

- Base Temperature (°F)

- Base Pressure (psi)

- Capacity/Required Flow Rate (MMSCFD)

- Gas Specific Gravity (Relative to air)

- Gas Molecular Weight

- C – Factor

- Compressibility Factor

- Z – Compressibility Factor

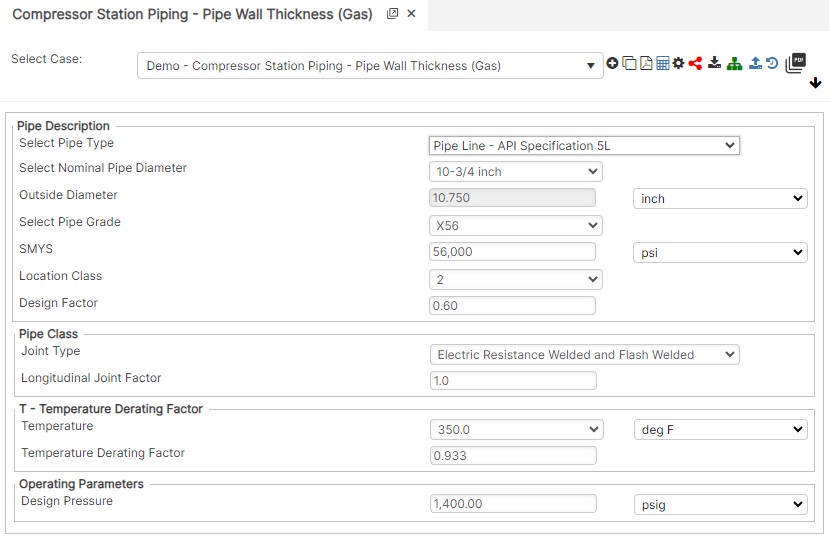

- Outside Diameter (in)

- SMYS (psi)

- Design Factor

- Joint Type

- Temperature Derating Factor

- Design Pressure (psig)

Gas Velocity

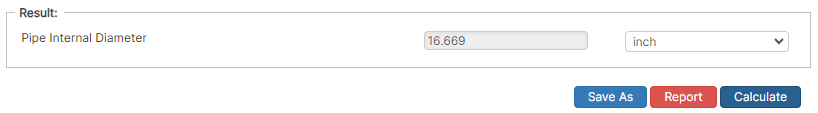

Pipe Diameter

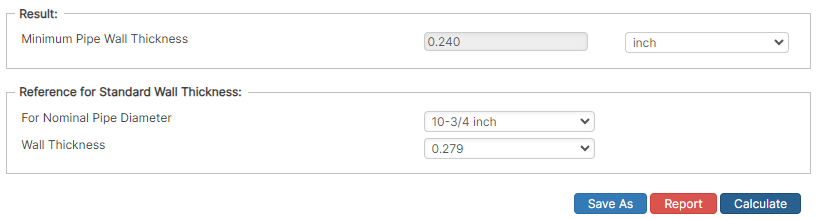

Wall Thickness

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

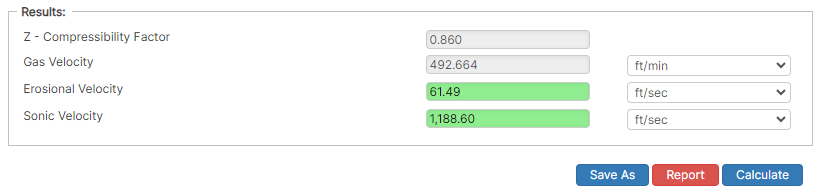

Results

- Z – Compressibility Factor

- Gas Velocity (ft/min)

- Erosional Velocity (ft/min)

- Sonic Velocity (ft/min)

- Pipe Internal Diameter (in)

- Minimum Pipe Wall Thickness (in)

Gas Velocity

Pipe Diameter

Wall Thickness

References

- Engineering Data Book, Volume 1, Gas Processors Suppliers Association, Tenth Edition

- Compressor Station Operation, Book T-2, GEOP, American Gas Association (A.G.A.)

- Compressor Selection and Sizing, Royce N. Brown, Second Edition, Gulf Professional Publishing