Introduction

Used for primarily water lines associated with production facilities. Limited to Reynolds numbers in the range of Re = 4,000 to 1,000000. Its chief drawback is that the Hazen-Williams coefficient is largely an experience factor which also depends on the viscosity of the product flowing.

Formulas

Downstream Pressure

P_2=P_1-GL\bigg( \frac{B}{0.006171C_{HW}D^{2.63})^{1.852}} \bigg)-\triangle H

P_2=P_1-GL\bigg( \frac{B}{0.006171C_{HW}D^{2.63})^{1.852}} \bigg)-\triangle HFlow Rate

B=0.006171C_{HW}D^{2.63}\bigg[ \frac{P_1-P_2-\triangle H}{GL} \bigg]^{0.54}

B=0.006171C_{HW}D^{2.63}\bigg[ \frac{P_1-P_2-\triangle H}{GL} \bigg]^{0.54}Internal Diameter

D=\bigg( \frac{0.006171C_{HW}(P_1-P_2-\triangle H}{(GL)^{0.54}} \bigg)^{0.38} \~\\triangle H=0.433514G(H_2-H_1) \~\ \triangle P=\frac{(P_1-P_2- \triangle H)}{L}

D=\bigg( \frac{0.006171C_{HW}(P_1-P_2-\triangle H}{(GL)^{0.54}} \bigg)^{0.38} \\~\\\triangle H=0.433514G(H_2-H_1) \\~\\ \triangle P=\frac{(P_1-P_2- \triangle H)}{L}Upstream Pressure

P_1=P_2+GL\bigg( \frac{B}{0.006171C_{HW}D^{2.63})^{1.852}} \bigg)-\triangle H

P_1=P_2+GL\bigg( \frac{B}{0.006171C_{HW}D^{2.63})^{1.852}} \bigg)-\triangle H𝐶𝐻𝑊 – Hazen − Williams Coefficient

𝐻1 − Upstream Elevation[ft]

𝐻2 − Downstream Elevation[ft]

𝐻 − Head Loss[ft]

𝐷−Pipe Internal Diameter[in]

𝐿 − Pipeline Length[mi]

𝐺 − Liquid Specific Gravity

∆𝑃 − Pressure Drop[psi/mile]

𝑃1 − Upstream Pressure[psig]

𝑃2 − Downstream Pressure[psig]

Case Guide

Part 1: Create Case

- Select the Hazen – Williams application in the Hydraulics module.

- To create a new case, click the “Add Case” button.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results

Input Parameters

- Temperature base(°F)

- Pressure base(psia)

- Gas Flowing Temperature(°F)

- Gas Specific Gravity

- Compressibility Factor

- Pipeline Efficiency Factor

- Upstream Pressure(psig)

- Downstream Pressure(psig)

- Flow Rate(Barrels per Day)

- Internal Pipe Diameter(in)

- Length of Pipeline(mi)

- Upstream Elevation(ft)

- Downstream Elevation(ft)

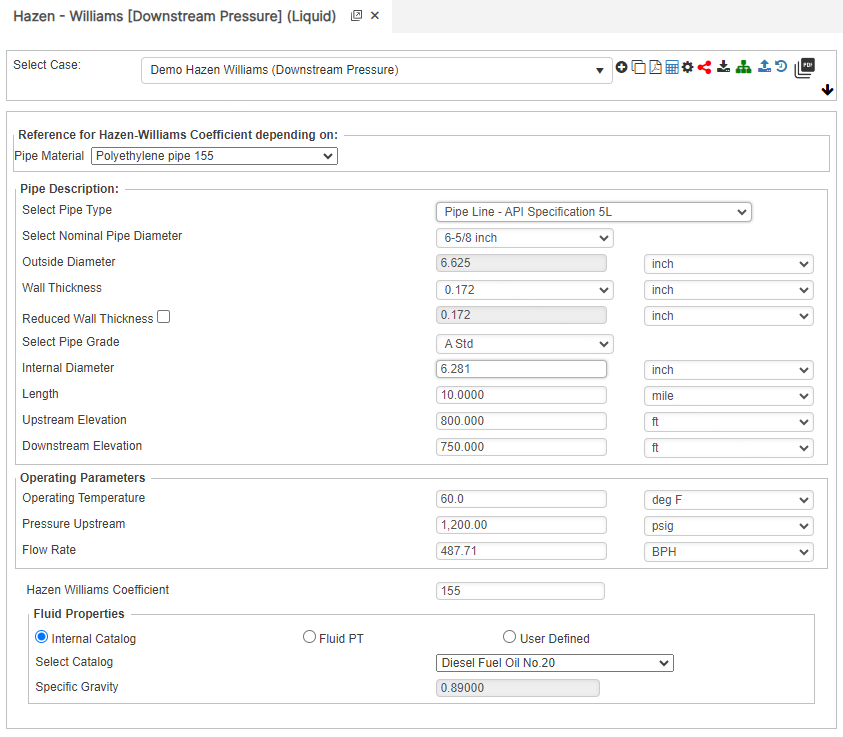

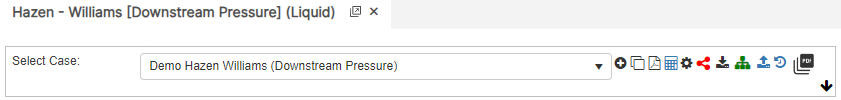

Downstream Pressure

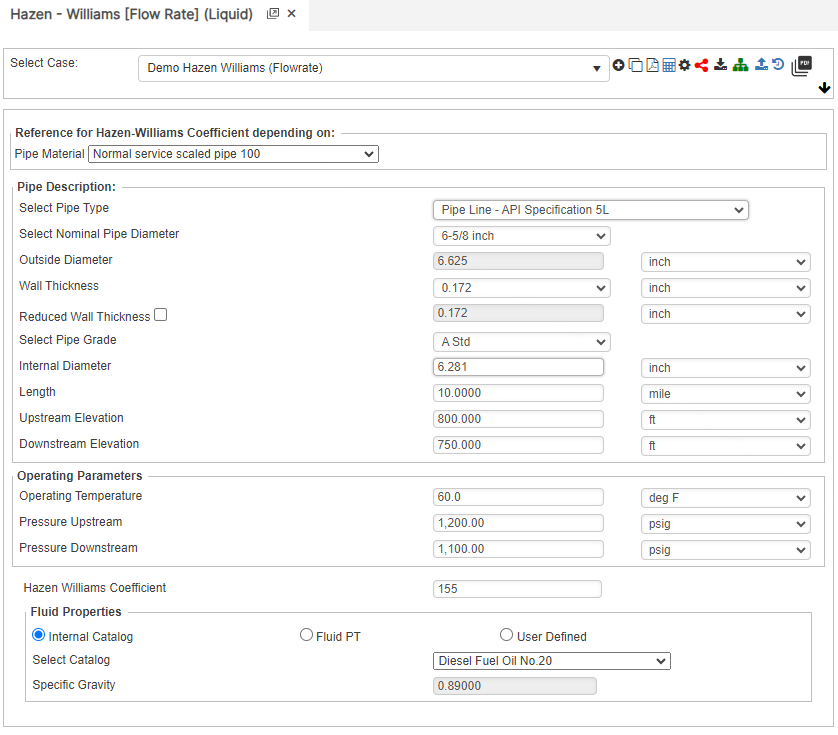

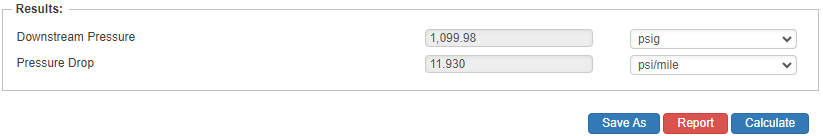

Flow Rate

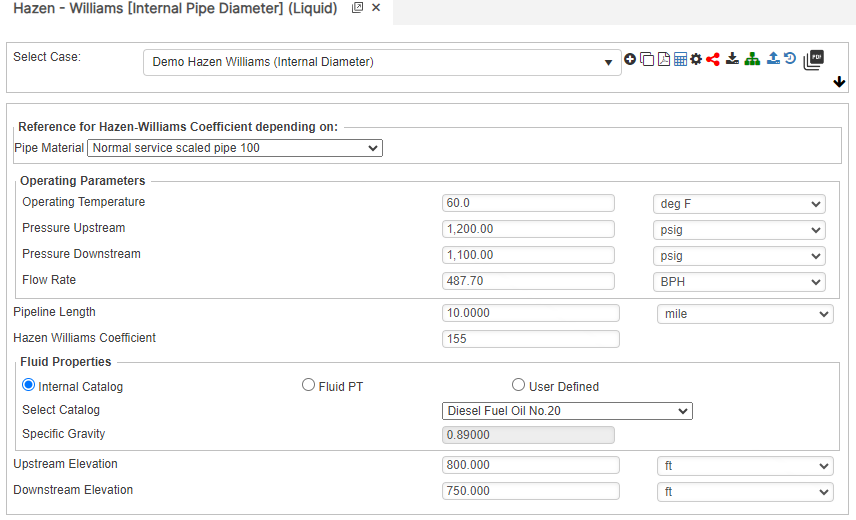

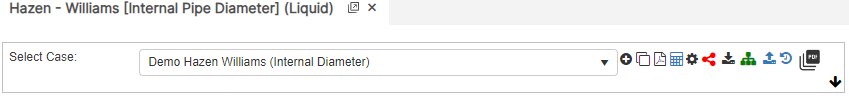

Internal Pipe Diameter

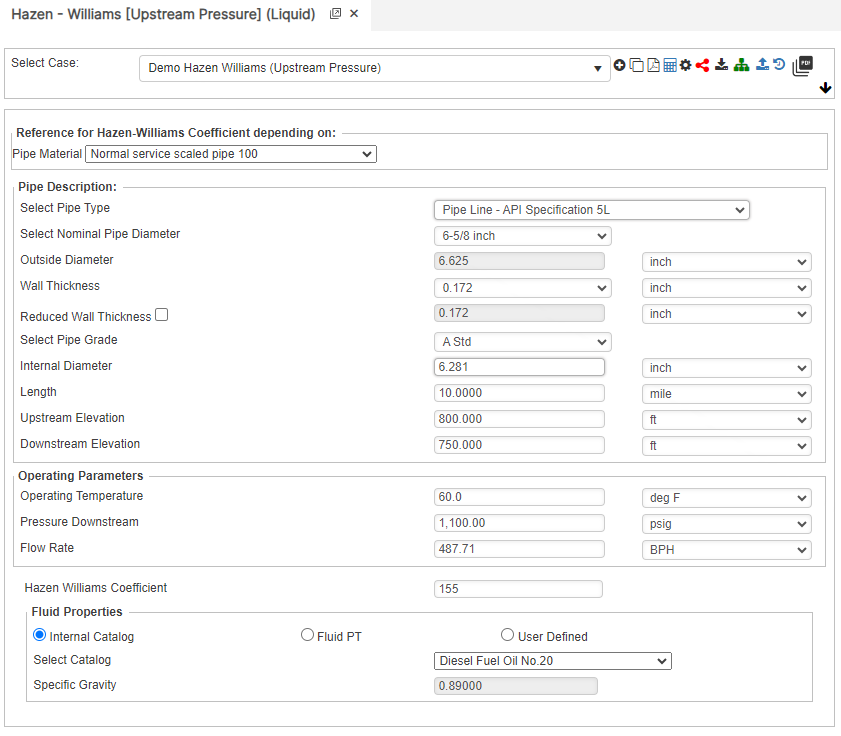

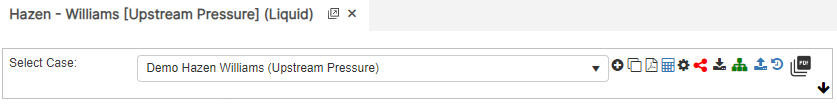

Upstream Pressure

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

Results

- Pressure Drop(psi/mile)

- Downstream Pressure(psig)

- Flow Rate(Barrels per Day)

- Internal Pipe Diameter(in)

- Upstream Pressure(psig)

Downstream Pressure

Flow Rate

Internal Pipe Diameter

Upstream Pressure

References

- “Pipeline Rules of Thumb” Gulf Professional Publishing, Seventh Edition, McAllister, E. W.

- “Gas Pipeline Hydraulics”, Systek Technologies, Inc., Menon, Shahi E.

- “Advanced Pipeline Design”, Carroll, Landon and Hudkins, Weston R.

- American Gas Association (AGA), “Reference: Eq-17-18, Section 17, GPSA”, Engineering Data Book, Eleventh Edition

- Hydraulic Transients, McGraw-Hill, New York., Streeter, V.L. and Wylie, E.B. (1967)

- Water Hammer Analysis. Jour. Hyd. Div., ASCE., Vol. 88, HY3, pp79-113 May, Streeter, V.L. (1969)

- Unsteady flow calculations by numerical methods’, Jour. Basic Eng., ASME., 94, pp457-466, June. Streeter, V.L. (1972),

- Hydraulic Pipelines, John Wiley & Sons, J. P Tullis (1989)

FAQ

-

What is Erosional Velocity?

Pipe erosion begins when velocity exceeds the value of C/SQRT(ρ) in ft/s, where ρ = gas density (in lb./ft3) and C = empirical constant (in lb./s/ft2) (starting erosional velocity). We used C=100 as API RP 14E (1984). However, this value can be changed based on the internal conditions of the pipeline. Check Out

-

What is Sonic Velocity?

The maximum possible velocity of a compressible fluid in a pipe is called sonic velocity. Oilfield liquids are semi-compressible, due to dissolved gases. Check Out