Introduction

Parallel explosive charge are complex methods which have been simplified in many cases to into equivalent parallel line or point sources. The estimate of the standard error for parallel equations can be as high as 34%; However, if the standoff distance between the pipe and explosive line is greater, then it can be approximated by a single point source. : A=R

A=R

The minimum distance from the pipeline to the nearest explosive charge must be greater than two times the outside pipe diameter. : A<\frac{2D}{12}\~\S_h=\frac{PD}{2t}

A<\frac{2D}{12}\\~

\\S_h=\frac{PD}{2t}Where:

R − Distance from the Charge to the Pipeline(ft)

P − MAOP−Maximum Allowable Operating Pressure(psi)

D − Pipeline Outside Diameter(in)

t − Pipe Wall Thickness(in)

Sℎ − Hoop Stress(psi)

L=N_1L_1\~\W=N_1W_1

L=N_1L_1\\~\\W=N_1W_1

Where:

L − Total Length of Explosive Line(ft)

L1 − Spacing Length Between Charges in Explosive Line(ft)

W − Total Charge Weight(lbs)

W1 − Weight of Single Charge(lbs)

N1 − Number of Charges in Explosive Line

\begin{align} \text{If } R >L: \ & S_c = 4.44E \left( \frac{nW}{\sqrt{(Et)(R^{2.5})}} \right)^{0.77} \ \text{If } R < L: \ & S_c = 4.44E \left( \frac{1.4n \frac{W_1}{L_1}}{\sqrt{(Et)(R^{1.5})}} \right)^{0.77}\ \text{A=R:}\ & S_{nc} = 4.44E \left( \frac{nW_1}{\sqrt{(Et)(A^{2.5})}} \right)^{0.77}\ \text{If } S_{nc} > S_c \text{ Then } S_c = S_{nc} \ &S_t=S_H+S_c\ &S=\sqrt{S_t^2-(S_tS_c)+S_c^2} \end{align}\

\begin{align*}

\text{If } R >L: \\

& S_c = 4.44E \left( \frac{nW}{\sqrt{(Et)(R^{2.5})}} \right)^{0.77} \\

\text{If } R < L: \\

& S_c = 4.44E \left( \frac{1.4n \frac{W_1}{L_1}}{\sqrt{(Et)(R^{1.5})}} \right)^{0.77}\\

\text{A=R:}\\

& S_{nc} = 4.44E \left( \frac{nW_1}{\sqrt{(Et)(A^{2.5})}} \right)^{0.77}\\

\text{If } S_{nc} > S_c \text{ Then } S_c = S_{nc} \\

&S_t=S_H+S_c\\

&S=\sqrt{S_t^2-(S_tS_c)+S_c^2}

\end{align*}\\

Where:

S𝑐 − Maximum Circumferential = S𝑙 − Maximum Longitudinal Stress(psi)

n − Equivalent Energy Release Ratio

W − Weight of Single Charge(lbs)

E − Modulus of Elasticity

t − Pipe Wall Thickness(in)

S𝑡 − Combined Hoop and Circumferential Stress(psi)

Calculated\,\%\,SMYS=\frac{S}{SMYS}100

Calculated\,\%\,SMYS=\frac{S}{SMYS}100Blasting Conditions for combined Stress Level

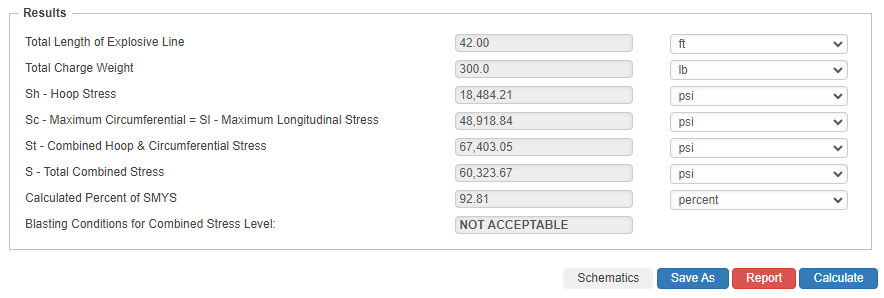

𝐶𝑎𝑙𝑆𝑀𝑌𝑆 >%𝑆𝑀𝑌𝑆 − NOT ACCEPTABLE/𝐶𝑎𝑙𝑆𝑀𝑌𝑆 <%𝑆𝑀𝑌𝑆 − ACCEPTABLE

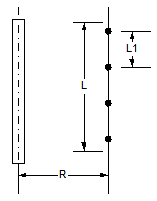

Schematics

N1 – Number of Charges in Explosive Line

L1 – Spacing Length Between Charges in Explosive Line

L – Length of an Explosive Line

W1 – Weight of Each Charge in Explosive Line

R – Perpendicular Distance of the Explosive Line to Pipeline

Case Guide

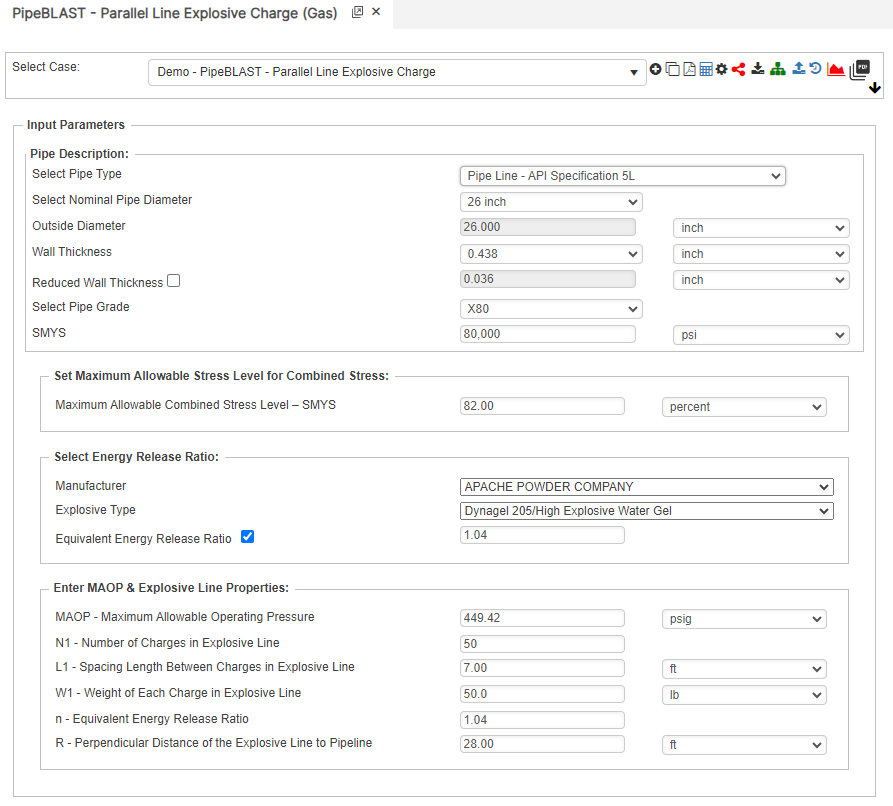

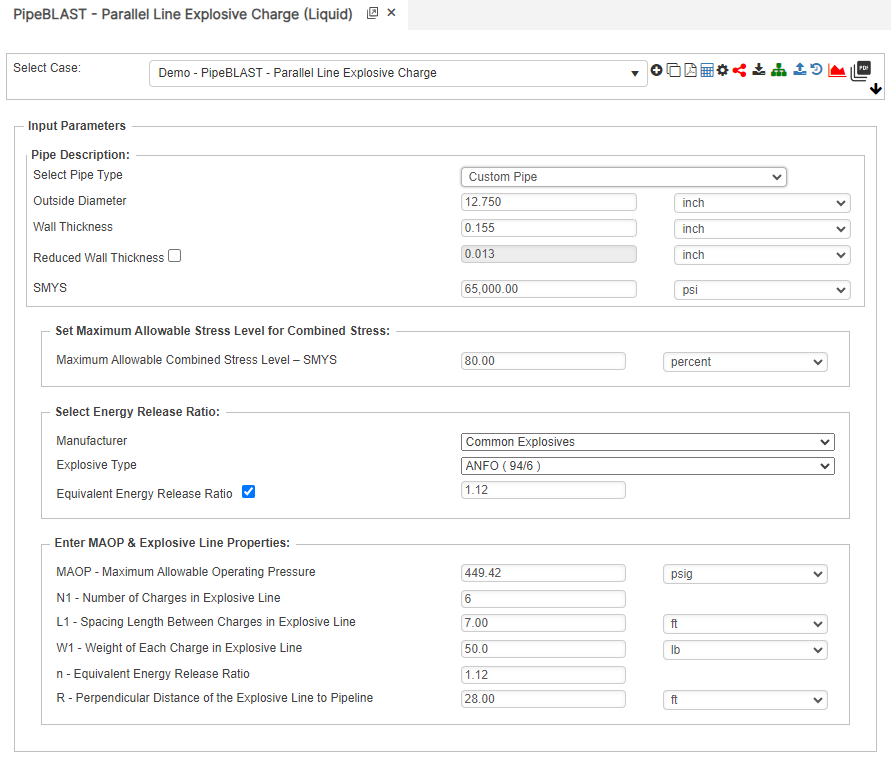

Part 1: Create Case

- Select the Parallel Line Explosive Charge application from the Pipe Blast module.

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date, and any necessary notes.

- Fill out all required parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

Input Parameters

- Pipe Outside Diameter

- Pipe Wall Thickness

- Specified Minimum Yield Strength

- Maximum Allowable Combined Stress Level – SMYS

- Manufacturer

- Explosive Type

- Equivalent energy release ratio

- MAOP – Maximum Allowable Operating Pressure

- N1 – Number of Charges in Explosive Line

- L1 – Spacing Length Between Charges in Explosive Line

- W1 – Weight of Single Charge

- n – Equivalent Energy Release Ratio

- R – Distance of the Charge to Pipeline

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

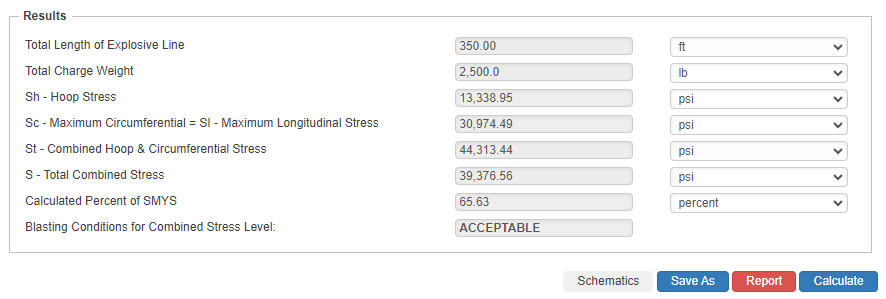

Results

- Total Length of Explosive Line

- Total Charge Weight

- Sh – Hoop Stress

- Sc-Maximum Circumferential = Sl-Maximum Longitudinal Stress

- St – Combined Hoop && Circumferential Stress

- S – Total Combined Stress

- Calculated Percent of SMYS

- Blasting Conditions for Combined Stress Level:

References

- SWRI – Pipeline Response to Buried Explosive Detonations – Volume I

- SWRI – Pipeline Response to Buried Explosive Detonations – Volume II

- PRCI – Pipeline Response to Blasting in Rock

FAQ

-

What Are The Blasting Calculations Used Around Pipelines?

Many oil, and gas pipeline companies have minimum requirements regarding blasting around their pipeline facilities. A common blasting requirement is blasting within 200 feet or using vibratory equipment within 25 feet of a pipeline. Unfortunately, blasting take places at very close proximities due to construction and other real activities such sewer, water, cable, etc. that cause stresses to these pipelines. Check Out

-

Estimating Equivalent Release Ratio?

Most chemical explosives have close to the same energy release per unit weight (We). If the explosive being used in a blasting situation is not known, the prediction equations can be used substituting a “typical” value for (We). Check Out