Introduction

Pipe wall thickness (WT) is based pipe diameter, SMYS, internal design pressure/factor, joint factor and sum of allowance WT. t_n=t+A\~\t=\frac{P_iD}{2S}

t_n=t+A\\~\\t=\frac{P_iD}{2S}Where:

𝑡𝑛−Nominal Wall Thickness Satisfying Requirements for Pressure and Allowances (in)

𝑡−Pressure Design Wall Thickness (in)

𝐴−Sum of Allowances for Threading and Grooving

𝑃𝑖 − Internal Design Gauge Pressure (psig)

𝐷 − Outside Pipe Diameter (in)

𝑆 − Applicable Allowable Stress Value (psi)

Case Guide

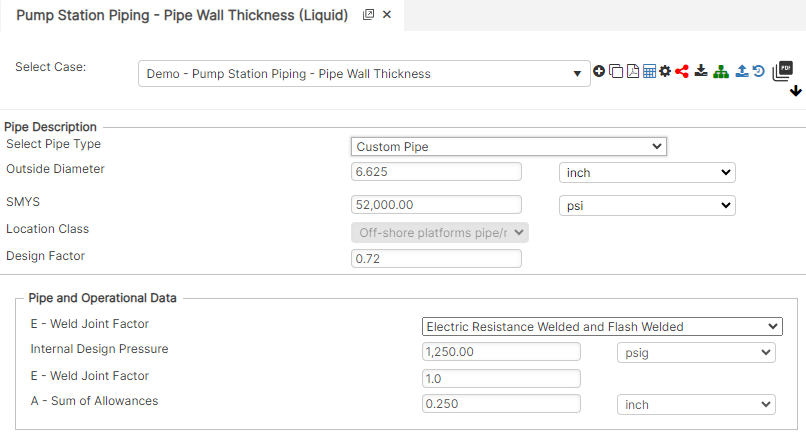

Part 1: Create Case

- Select the Pump Station Piping application from the Pump Module

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required Parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

Input Parameters

- Nominal Pipe Size (in)

- Pipe Grade (if pipe grade is unknown use Grade A 24000)

- Wall Thickness (in)

- E – Longitudinal Joint Factor

- F – Design Factor

- Internal Design Pressure (psi)

- A – Sum of Allowances (in)

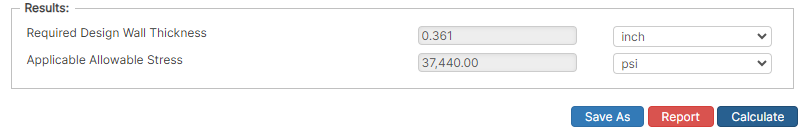

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

Results

- Required Design Wall Thickness (in)

- Applicable Allowable Stress (psi)

References

- ASME B31.4 – 1998 Edition “Pipeline Transportation Systems for Liquid Hydrocarbons and other Liquids”, Art. 404.1

- API 1117 – Movement of In-Service Pipelines

- API 5L, API 5LS and API 5LX – Specification of Pipe Grade

- ASTM – Various – Weld Joint Factor

- CFR Code Part 192

- MMS Regulations

- USDA-SCS Modified (Permissible Velocity of Water and Soil Erodibility)

- Pipeline Rules of Thumb Handbook