Introduction

This application uses a positive displacement compressor model to deliver gases at high pressures. With piston displacement reciprocating compressors, often final outlet temp could be a concern.

Piston Displacement

Single-Acting Piston Compression on the Outer End Only: PD = \frac{sn\pi D^2}{4 \times 1728}

PD = \frac{sn\pi D^2}{4 \times 1728}

Single-Acting Piston Compression on the Crank End Only: PD = \frac{sn\pi (D^2 – d^2)}{4 \times 1728}

PD = \frac{sn\pi (D^2 - d^2)}{4 \times 1728}

Double-Acting Piston Compression (Other than Tail Rod Type): PD = \frac{sn\pi (2D^2 – d^2)}{4 \times 1728}

PD = \frac{sn\pi (2D^2 - d^2)}{4 \times 1728}

Double-Acting Piston Compression (With a Tail Rod): PD = \frac{2sn\pi (D^2 – d^2)}{4 \times 1728}

PD = \frac{2sn\pi (D^2 - d^2)}{4 \times 1728}

Where:

𝑃𝐷 − Piston Displacement (ft3/min)

𝑠 − Stroke (𝑖𝑛)

𝑛 − Rotational Speed (rpm)

𝐷 − Cylinder Inside Diameter (in)

𝑑 − Piston Rod Diameter (in)

Reciprocating Compressor Volumetric Efficiency

VE = 100 – A – L_u – r – C \left[ \frac{Z_s}{Z_d} \left( r^{\frac{1}{k}} \right) – 1 \right]

VE = 100 - A - L_u - r - C \left[ \frac{Z_s}{Z_d} \left( r^{\frac{1}{k}} \right) - 1 \right]

Where:

𝑉𝐸 − Volumetric Efficiency (%)

𝐴 − Effect of Leakage, Losses etc. (%)

𝐿𝑢 − Effect due to Lack of Lubrication (%)

𝑟 − Compression Ratio (𝑃2/𝑃1)

𝐶 − Cylinder Clearance as a Percent of Cylinder Volume (%)

𝑧𝑠 − Compressibility Factor at Suction Conditions

𝑧𝑑 − Compressibility Factor at Discharge Conditions

𝑘 − Adiabatic/Isentropic Exponent (𝑐𝑝/𝑐𝑣)

In practice for normal operation

VE = 96 – r – C \left[ \frac{Z_s}{Z_d} \left( r^{\frac{1}{k}} \right) – 1 \right]

VE = 96 - r - C \left[ \frac{Z_s}{Z_d} \left( r^{\frac{1}{k}} \right) - 1 \right]CNGA/GPSA Compressibility Factor Approximation:

Z=\frac{1}{\left[1+\left(\frac{3.444\times10^5P\times10^{1.785G}}{T_f^{3.825}} \right)\right]}

Z=\frac{1}{\left[1+\left(\frac{3.444\times10^5P\times10^{1.785G}}{T_f^{3.825}} \right)\right]}Where:

𝑍 − Compressibility Factor

𝑃 − Pressure

𝑇𝑓 − Gas Flowing Temperature (°𝑅)

This approximation will produce results sufficiently accurate for preliminary calculations.

Q_{\text{actual}} = PD \frac{VE}{100} \quad [\text{ft}^3/\text{min}] \text{(ACFM)} \~\ Q_{\text{actual}} = PD \cdot VE\frac{P_1}{P_b} \cdot 14.4 \times 10^{-5} \quad [\text{MMCFD}] \~\ Q_{st} = Q_{\text{actual}} \frac{P_1}{P_b}\frac{T_b}{T_1}\frac{Z_b}{Z_1} \quad [\text{MMSCFD}]

Q_{\text{actual}} = PD \frac{VE}{100} \quad [\text{ft}^3/\text{min}] \text{(ACFM)} \\~\\ Q_{\text{actual}} = PD \cdot VE\frac{P_1}{P_b} \cdot 14.4 \times 10^{-5} \quad [\text{MMCFD}] \\~\\ Q_{st} = Q_{\text{actual}} \frac{P_1}{P_b}\frac{T_b}{T_1}\frac{Z_b}{Z_1} \quad [\text{MMSCFD}]

Reciprocating Compressor Horsepower

HP=\frac{144}{33000}\left( \frac{P_1Q}{n}\right)\left(\frac{k}{k-1} \right)\left[ (r)^{\frac{k-1}{k}}-1\right] [HP]

HP=\frac{144}{33000}\left( \frac{P_1Q}{n}\right)\left(\frac{k}{k-1} \right)\left[ (r)^{\frac{k-1}{k}}-1\right] [HP]Where:

𝑄 − Suction Capacity (SCFM)

𝑃1 − Gas Suction Pressure (psi)

𝑛 − Compressor Efficiency

𝑘 = (𝑐𝑝/𝑐𝑣) − Specific Heat Ratio

𝑟 − Compression Ratio (𝑃2/𝑃1)

Ideal Discharge Temperature

T_{2(\text{ideal})} = T_1 \left[ (r)^{\frac{k-1}{k}} – 1 \right]

T_{2(\text{ideal})} = T_1 \left[ (r)^{\frac{k-1}{k}} - 1 \right]

Where:

𝑇2(𝑖𝑑𝑒𝑎𝑙) − Ideal Discharge Temperature (°R)

𝑇1 − Suction Temperature (°R)

𝑟 − Compression Ratio (P2/P1)

𝑘 − 𝐴diabatic/Isentropic Exponent (𝑘=[𝑐𝑝/𝑐𝑣])

Theoretical Discharge Temperature

\Delta T_{\text{ideal}} = T_1 \left[ (r)^{\frac{k-1}{k}} – 1 \right]

\Delta T_{\text{ideal}} = T_1 \left[ (r)^{\frac{k-1}{k}} - 1 \right]

Where:

𝑇2 = 𝑇1+Δ𝑇𝑖𝑑𝑒𝑎𝑙

𝑇2 − Theoretical Discharge Temperature (°R)

Actual Discharge Temperature

\Delta T_{\text{actual}} = T_1 \frac{\left[ (r)^{\frac{k-1}{k}} – 1 \right]}{ {n_a}}

\Delta T_{\text{actual}} = T_1 \frac{\left[ (r)^{\frac{k-1}{k}} - 1 \right]}{ {n_a}}

Where:

𝑇2 = 𝑇1+Δ𝑇𝑎𝑐𝑡𝑢𝑎𝑙

𝑇2 − Actual Discharge Temperature (°R)

𝑛𝑎 − Adiabatic (Isentropic) Efficiency

Case Guide

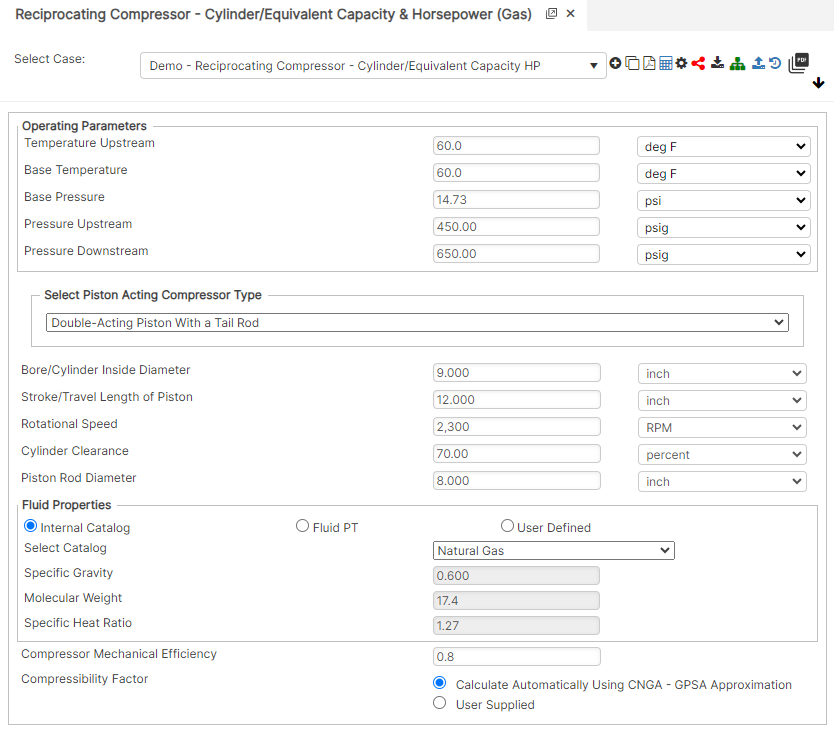

Part 1: Create Case

- Select the Adiabatic Head application from the Compressor Module

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required Parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

Input Parameters

- Suction Temperature Upstream (°F)

- Base Temperature (°F)

- Base Pressure (psi)

- Suction Pressure Upstream (psig)

- Discharge Pressure Downstream (psig)

- Bore/Cylinder Inside Diameter (in)

- Stroke/Travel Length of Piston (in)

- Rotational Speed (rpm)

- Cylinder Clearance (%)

- Piston Rod Diameter (in)

- Capacity/Required Flow Rate (MMSCFD)

- Gas Specific Gravity (Relative to air)

- Gas Molecular Weight

- Gas Specific Heat Ratio

- Compressor Mechanical Efficiency

- Compressibility Factor

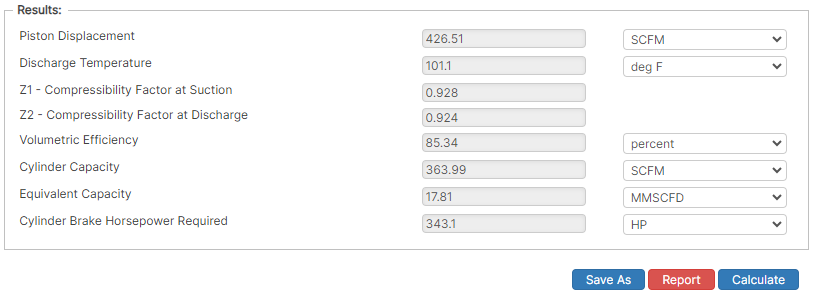

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

Results

- Piston Displacement (ft³/min)

- Discharge Temperature (°F)

- Z1 – Compressibility Factor at Suction

- Z2 – Compressibility Factor at Discharge

- Volumetric Efficiency (%)

- Cylinder Capacity (SCFM)

- Equivalent Capacity (MMSCFD)

- Cylinder Brake Horsepower Required (HP)

References

- Engineering Data Book, Volume 1, Gas Processors Suppliers Association, Tenth Edition

- Compressor Station Operation, Book T-2, GEOP, American Gas Association (A.G.A.)

- Compressor Selection and Sizing, Royce N. Brown, Second Edition, Gulf Professional Publishing