Introduction

A Reciprocating Pump uses reciprocating motion to cause a fluid to be moved from one location to another. The most common is the positive displacement type.

Capacity is limited by the pump speed and number of plungers/pistons available along with other mechanical considerations such as the crankshaft and slider mechanism.

PD = \frac{Asnm}{231} \quad \text{— Single Acting Pump} \~\

PD = \frac{(2A-a)snm}{231} \quad \text{— Double Acting Piston Pump (No Tail Rod(s))}

PD = \frac{Asnm}{231} \quad \text{— Single Acting Pump} \\~\\

PD = \frac{(2A-a)snm}{231} \quad \text{— Double Acting Piston Pump (No Tail Rod(s))}

Where:

𝑃𝐷 − Displacement is the Volume Swept by all Pistons or Plungers per Unit of Time (gpm)

𝐴 − Piston or Plunger Area (in2)

𝑎 − Piston Rod Cross Sectional Area (in2) (Double Acting Piston Pump)

𝑠 − Stroke Length (in)

𝑛 − Crankshaft Rotational Speed (rpm)

𝑚 − Number of Pistons or Plungers

Actual Capacity

Q=nPD\cdot VE

Q=nPD\cdot VE

Where:

𝑄 − Actual Pump Capacity (gpm)

𝑛 − Number of Pistons/Plungers

𝑉𝐸 − Volumetric Efficiency (Fraction)

Case Guide

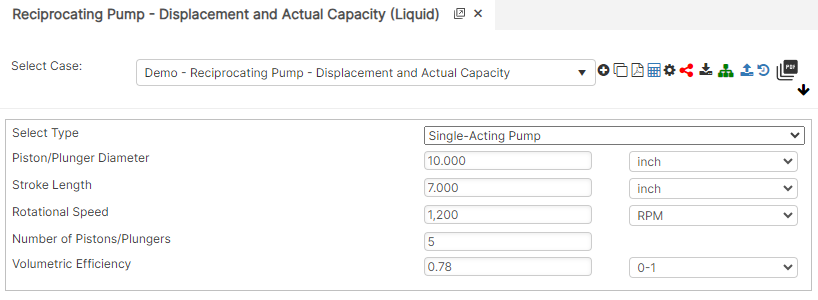

Part 1: Create Case

- Select the Reciprocating Pump – Displacement and Actual Capacity application from the Pump Module

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required Parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

Input Parameters

- Piston/Plunger Diameter (in)

- Stroke Length (in)

- Rotational Speed (rpm)

- Number of Pistons/Plungers

- Volumetric Efficiency (Fraction)

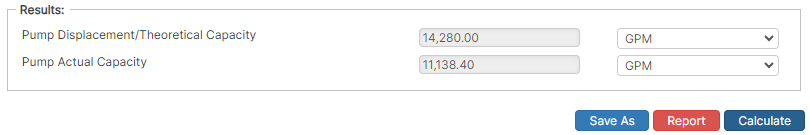

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

Results

- Pump Displacement/Theoretical Capacity (gpm)

- Pump Actual Capacity (gpm)

References

- ASME B31.4 – 1998 Edition “Pipeline Transportation Systems for Liquid Hydrocarbons and other Liquids”, Art. 404.1

- API 1117 – Movement of In-Service Pipelines

- API 5L, API 5LS and API 5LX – Specification of Pipe Grade

- ASTM – Various – Weld Joint Factor

- CFR Code Part 192

- MMS Regulations

- USDA-SCS Modified (Permissible Velocity of Water and Soil Erodibility)

- Pipeline Rules of Thumb Handbook