Introduction

Sizing of regulator is performed using the Universal Gas Equation:

Subsonic Flow Equation

Q = C_{g} P_1 \sqrt{\frac{520}{G_f T} \sin \left[ \left(\frac{3417}{C_1}\right) \sqrt{\frac{\Delta P}{P_1}} \right]}

Q = C_{g} P_1 \sqrt{\frac{520}{G_f T} \sin \left[ \left(\frac{3417}{C_1}\right) \sqrt{\frac{\Delta P}{P_1}} \right]}

Where:

𝑄 =Gas Flowrate (scf/h)

𝐺𝑓 = Gas Specific Gravity

𝑇 = Absolute Temperature (°R)

𝐶𝑔 = Gas Sizing Coefficient

𝐶𝑣 = Liquid Sizing Coefficient

𝐶1 = 𝐶𝑔/𝐶𝑣

𝑃1 = Gas Sizing Coefficient

Δ𝑃 = 𝑃1 − 𝑃2 − Differential Pressure Across Valve

𝑃2 = Outlet Pressure (psia)

Sonic Flow Equation is Reduced to:

Q=C_gP_1\sqrt{\frac{520}{G_fT}}

Q=C_gP_1\sqrt{\frac{520}{G_fT}}Case Guide

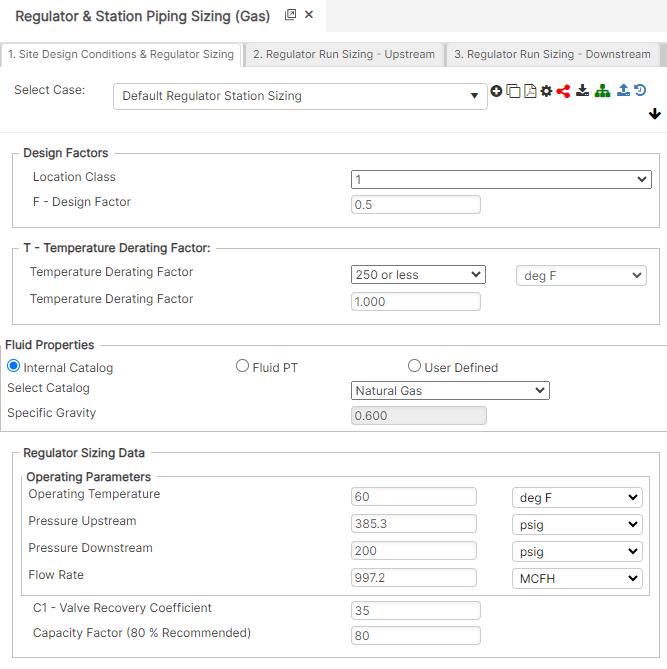

Part 1: Create Case

- Select the Regulator & Station Piping Sizing application from the Regulator & Meters Module

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required Parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

Input Parameters

- Class Location

- Temperature

- F – Design Factor

- T – Temperature Derating Factor

- Gas Specific Gravity

- Regulator Sizing Data

- P1 – Inlet Pressure

- P2 – Outlet Pressure

- Q – Flow Rate

- Gas Specific Gravity

- Flowing Gas Temperature

- C1 – Valve Recovery Coefficient

- Capacity Factor (80% Recommended)

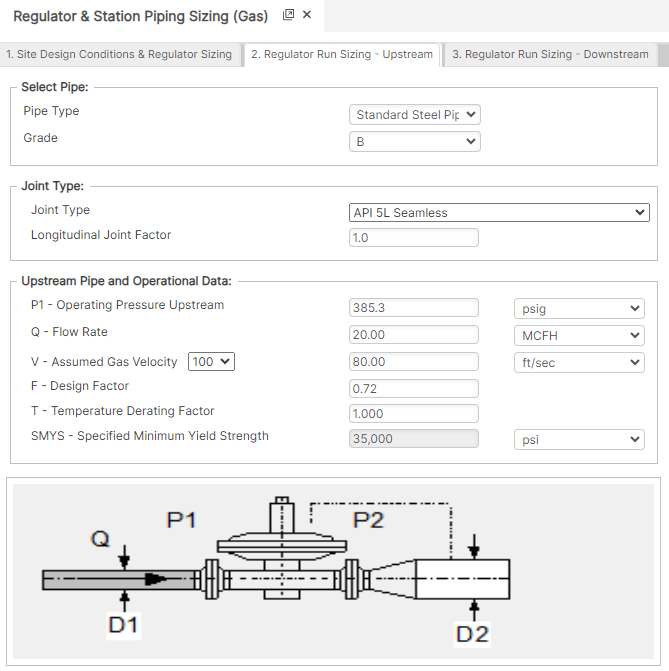

- Upstream Pipe and Operational Data

- P1 – Operating Pressure – Upstream

- Q – Flow Rate

- V – Assumed Gas Velocity

- F – Design Factor

- T – Temperature Derating Factor

- SMYS – Specified Minimum Yield Strength

- E – Longitudinal Joint Factor

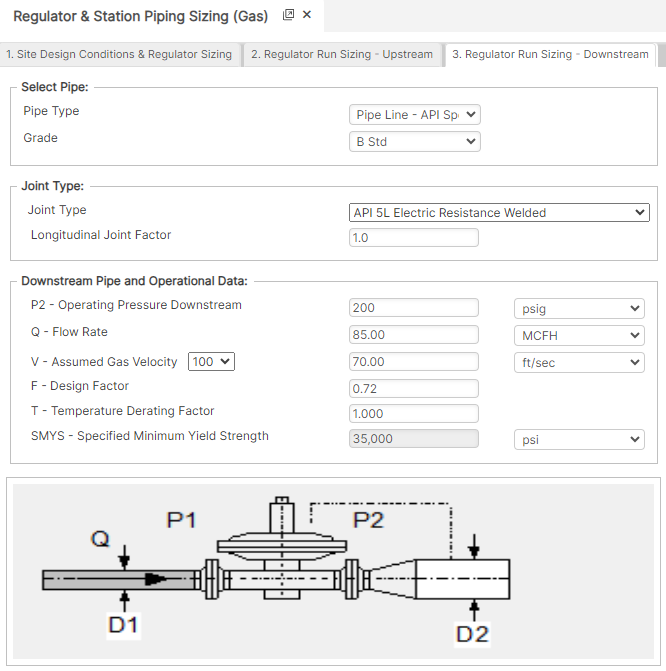

- Downstream Pipe Operational Data

- P2 – Operating Pressure – Downstream

- Q – Flow Rate

- V – Assumed Gas Velocity

- F – Design Factor

- T – Temperature Derating Factor

- SMYS – Specified Minimum Yield Strength

- E – Longitudinal Joint Factor

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

Results

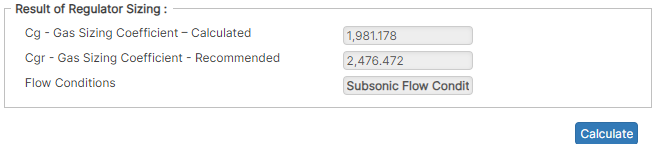

- Regulator Sizing Results

- Cg – Gas Sizing Coefficient – Calculated

- Cgr – Gas Sizing Coefficient – Recommended

- Flow Conditions:

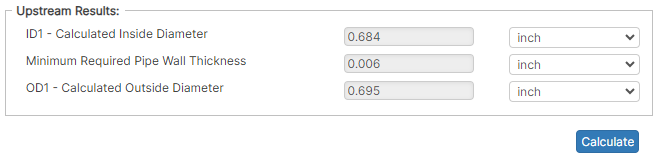

- Upstream Results

- ID1 – Calculated Inside Diameter (in)

- Minimum Required Pipe Wall Thickness (in)

- OD1 – Calculated Outside Diameter (in)

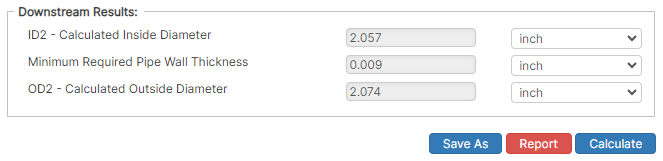

- Downstream Results

- ID1 – Calculated Inside Diameter (in)

- Minimum Required Pipe Wall Thickness (in)

- OD1 – Calculated Outside Diameter (in)

References

- AGA Report No. 3 – Orifice Metering of Natural Gas and other Related Hydrocarbon Fluid – Parts 1-4