Introduction

A single point charge is used in estimating the stress magnitudes to the pipe. :A=R

A=R

The minimum distance from the pipeline to the nearest explosive charge must be greater than two times the outside pipe diameter. A<\frac{2D}{12}\~\S_h=\frac{PD}{2t}

A<\frac{2D}{12}\\~

\\S_h=\frac{PD}{2t}Where:

R − Distance from the Charge to the Pipeline(ft)

P − MAOP−Maximum Allowable Operating Pressure(psi)

P − Pipeline Outside Diameter(in)

t − Pipe Wall Thickness(in)

Sℎ − Hoop Stress(psi)

S_c = 4.44E \left( \frac{nW}{\sqrt{(Et)(R^{2.5})}} \right)^{0.77} \~\ S_t=S_h+S_c\~\ S=\sqrt{S_t^2-(S_tS_c)+S_c^2}

S_c = 4.44E \left( \frac{nW}{\sqrt{(Et)}(R^{2.5})} \right)^{0.77} \\~\\ S_t=S_h+S_c\\~\\ S=\sqrt{S_t^2-(S_tS_c)+S_c^2}Where:

S𝑐 − Maximum Circumferential = S𝑙 − Maximum Longitudinal Stress(psi)

n − Equivalent Energy Release Ratio

W − Weight of Single Charge(lbs)

E − Modulus of Elasticity

t − Pipe Wall Thickness(in)

S𝑡 − Combined Hoop and Circumferential Stress(psi)

Calculated\,\%\,SMYS=\frac{S}{SMYS}100

Calculated\,\%\,SMYS=\frac{S}{SMYS}100Blasting Conditions for combined Stress Level

𝐶𝑎𝑙𝑆𝑀𝑌𝑆 >%𝑆𝑀𝑌𝑆 − NOT ACCEPTABLE/𝐶𝑎𝑙𝑆𝑀𝑌𝑆 <%𝑆𝑀𝑌𝑆 − ACCEPTABLE

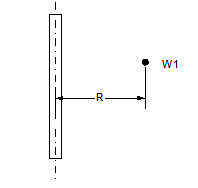

Schematics

W1 – Weight of Explosive Charge

R – Perpendicular Distance of the Explosive Charge to Pipeline

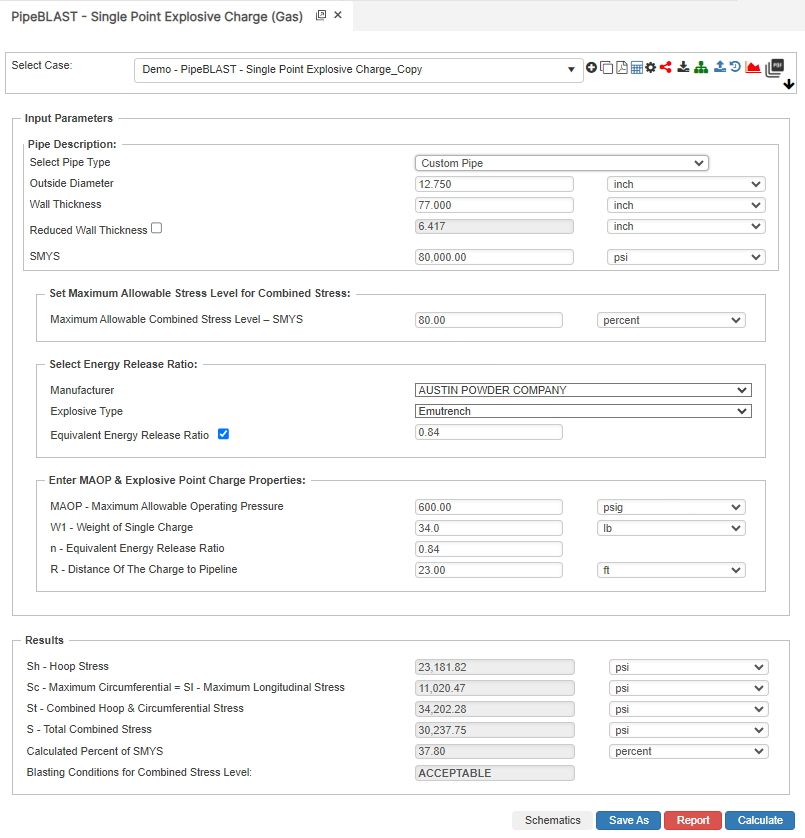

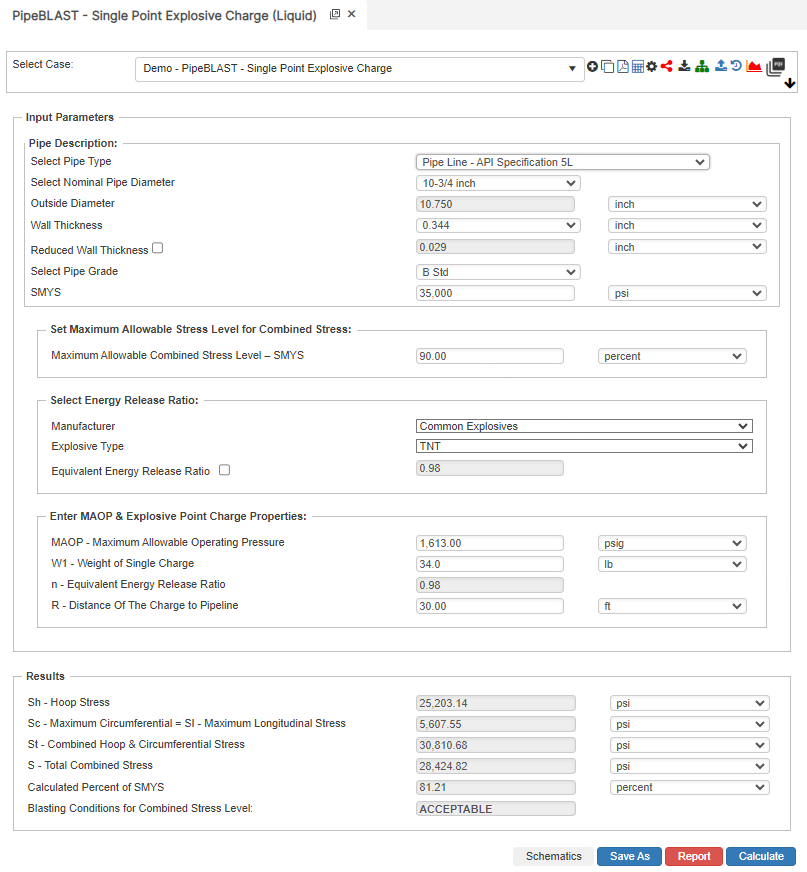

Case Guide

Part 1: Create Case

- Select the Single Point Explosive Charge application from the Pipe Blast module.

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

Input Parameters

- Pipe Outside Diameter

- Pipe Wall Thickness

- Specified Minimum Yield Strength

- Maximum Allowable Combined Stress Level – SMYS

- Manufacturer

- Explosive Type

- Equivalent energy release ratio

- MAOP – Maximum Allowable Operating Pressure

- W1 – Weight of Single Charge

- n – Equivalent Energy Release Ratio

- R – Distance of the Charge to Pipeline

Part 2: Outputs/Report

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

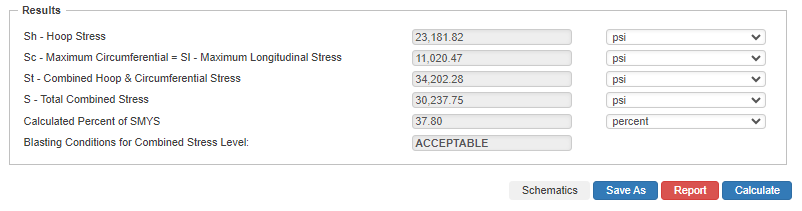

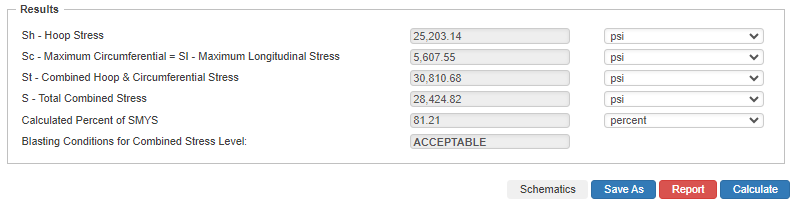

Results

- Sh – Hoop Stress

- Sc-Maximum Circumferential = Sl-Maximum Longitudinal Stress

- St – Combined Hoop && Circumferential Stress

- S – Total Combined Stress

- Calculated Percent of SMYS

- Blasting Conditions for Combined Stress Level:

References

- SWRI – Pipeline Response to Buried Explosive Detonations – Volume I

- SWRI – Pipeline Response to Buried Explosive Detonations – Volume II

- PRCI – Pipeline Response to Blasting in Rock

FAQ

-

What Are The Blasting Calculations Used Around Pipelines?

Many oil, and gas pipeline companies have minimum requirements regarding blasting around their pipeline facilities. A common blasting requirement is blasting within 200 feet or using vibratory equipment within 25 feet of a pipeline. Unfortunately, blasting take places at very close proximities due to construction and other real activities such sewer, water, cable, etc. that cause stresses to these pipelines. Check Out

-

Estimating Equivalent Release Ratio?

Most chemical explosives have close to the same energy release per unit weight (We). If the explosive being used in a blasting situation is not known, the prediction equations can be used substituting a “typical” value for (We). Check Out