Introduction

No pump is perfect with 100% efficiency. Energy lost in friction and hydraulic losses transforms to heat – heating up the fluid transported through the pump and the piping. PLTB calculates this temperature rise.

Throttling the discharge valve will result in a temperature increase. Reduced efficiency of pumps results in temperature increases. : t_y = \frac{H \left( \frac{1}{n} – 1 \right)}{780 c_p} [\text{\textdegree}F]

t_y = \frac{H \left( \frac{1}{n} - 1 \right)}{780 c_p} [\text{\textdegree}F]

Where:

𝑡𝑦 − Temperature Rise due to Pumping (℉)

𝐻 − Total Head (ft)

𝑛 − Pump Efficiency

𝑐𝑝 − Specific Heat (Btulb⁄℉)

Case Guide

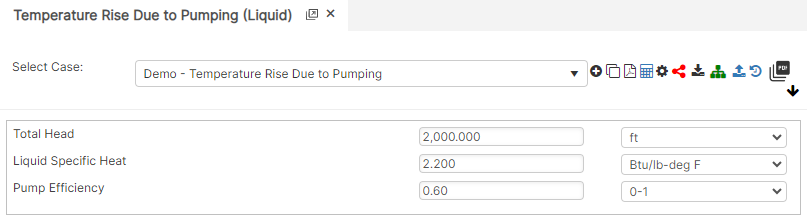

Part 1: Create Case

- Select the Temperature Rise Due to Pumping application from the Pump Module

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required Parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

Input Parameters

- Total Head (ft)

- Liquid Specific Heat (Btu/lb ˚F)

- Pump Efficiency (0-1)

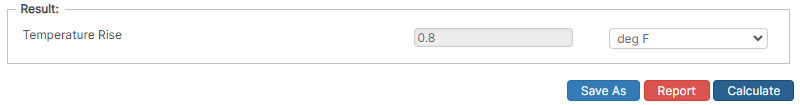

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

Results

- Temperature Rise (˚F)

References

- ASME B31.4 – 1998 Edition “Pipeline Transportation Systems for Liquid Hydrocarbons and other Liquids”, Art. 404.1

- API 1117 – Movement of In-Service Pipelines

- API 5L, API 5LS and API 5LX – Specification of Pipe Grade

- ASTM – Various – Weld Joint Factor

- CFR Code Part 192

- MMS Regulations

- USDA-SCS Modified (Permissible Velocity of Water and Soil Erodibility)

- Pipeline Rules of Thumb Handbook