Introduction

The Wheel Load Analysis Program was designed to calculate the overburden and vehicle loads on buried pipe with a Single Layer System (soil only) or a Double Layer Systems (timbers, pavement and soil). The information used to design this program was taken from the Battelle Petroleum Technology Report on “Evaluation of Buried Pipe Encroachments” which considered the theoretical work done by M.G. Spangler on overburden and vehicle loads on buried pipe.

Analysis Requirement

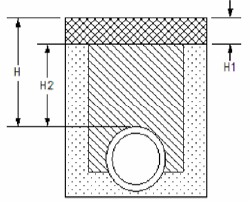

1. Depth of Carrier Pipe

- The depth of the carrier pipe, H, is measured from the top of pavement, rig mats, or soil (if neither pavement nor rig mats exist) to the pipeline crown.

- is used to establish the impact factor, Fi used in the design methodology.

- is calculated by H = H1 + H2

- H1 – Thickness of the pavement layer, if there is a pavement layer

- Rig mats are considered a part of the pavement layer

- Has units of inches (in)

- (see Figure 2)

- H2 – vertical depth from the ground to the top of the pipe

- If there is a surface layer of pavement or rig mats, this measurement begins at the bottom of that pavement layer

- Has units of feet (ft)

Trench Width

- Width of the trench, B, that was excavated during construction

- Has units of feet

Weight per unit Volume of Backfill

- Weight per unit Volume, Ds

- Has units of pounds per cubic foot (lb/ft3)

DIAMETER.

- The diameter, D, is the outside pipe diameter

- has units of inches.

- The range of D is 2.000 to 42.000 in.

- The default value is D = 12.750 in.

WALL THICKNESS.

- The pipe wall thickness, T, has units of inches.

- The wall thickness to diameter ratios must be within the range of wt./D = 0.01 to 0.08.

Concentrated Surface Load

- The concentrated surface load, Lw, is the force applied by the wheel to the ground, vs. the gross weight

- Has units of pounds (lbs)

- see Section 4

SPECIFIED MINIMUM YIELD STRENGTH.

- The specified minimum yield strength, SMYS,

- Has units of pounds per square inch (psi)

- has a range of allowable values covering steel grades A25 (SMYS = 25000 psi) to X-80 (SMYS = 80000 psi).

- The SMYS is also used to establish the girth and longitudinal weld fatigue endurance limits.

P – Pipe Internal Pressure (psi.)

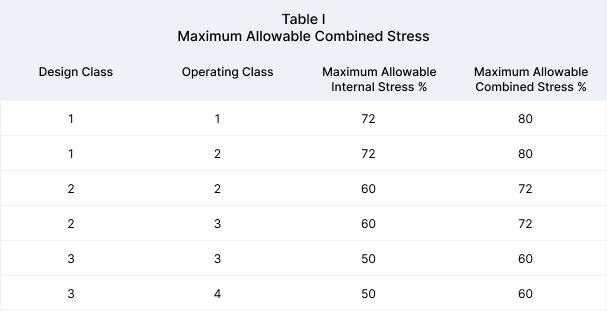

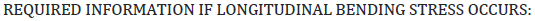

2. Design Class

- Design Class of the pipeline being analyzed is defined by §192.5 Class Locations

- The allowable range is from 1 to 4

- Is used to find the Maximum Allowable Combined Stress (% SMYS), see Table I.

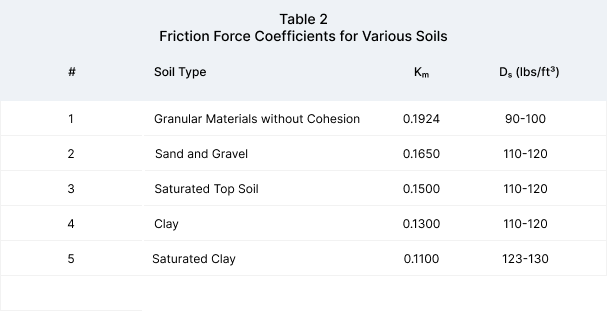

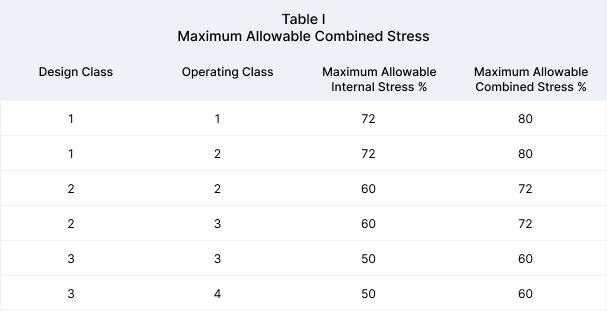

3. Soil Type

Which is used to find the friction force coefficients (Km)

- The soil types and coefficients given in this table represent the range that could normally be expected.

- Saturated clay has little internal friction so that it has the smallest value for Kμ. This implies that almost all of the soil load is carried by the pipe.

- Granular materials have a great deal more internal friction. Their value of Kμ is higher which leads us to the conclusion that the pipe carries less of the backfill load.

- Marsh and bog areas, however, have friction properties more similar to saturated clay such that a value for Km equal to 0.110 should be used in these areas.

- Spangler, in his work, recommends using the value for clay in most instances.

- Higher values may be used when there is adequate evidence that the internal friction is higher and warrants a higher value of Kμ.

- Spangler’s recommendation provides a conservative estimate for common buried pipe situations.

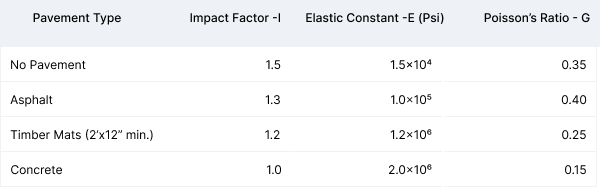

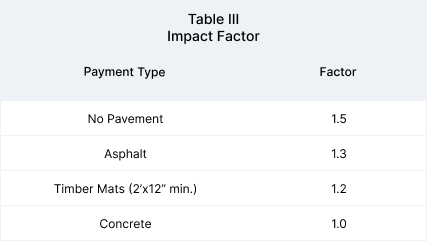

4. Pavement Type

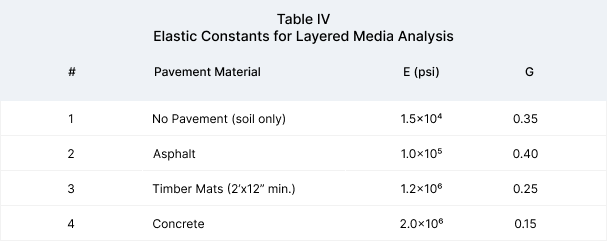

- Is used to find the elastic constants for layered media analysis (E1, E2, G1, & G2) see Table III & Figure 2.

- A Pavement Type must be determined in order to select an Impact Factor (I) to be used in the Wv equation

- The variables E1 & G1 will be used to represent the elastic constants for the top layer and E2 & G2 will be used to represent the elastic constants for the soil.

- See Figure 2 for a visual explanation of the elastic constants for the top layer and the soil.

- These values will also be used in the Wv equation.

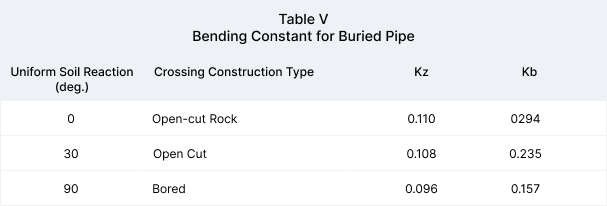

The Pipeline Construction Type which is used to find the bedding constants for buried pipe (Kb & Kz), see Table V & Figure 3.

All the above information, along with values for the following variables:

X – Longitudinal Distance over which Deflection occurs (ft.)

Y – Vertical Deflection (in.)

Calculations Procedure

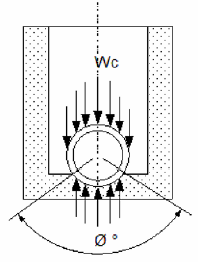

As a first estimate of the soil load on the pipe it could be assumed that the backfill soil slides down the 0trench walls without friction. Additionally, assume that all soil above the pipe is supported by the pipe itself and that the backfill soil on either side of the pipe does not assist in this support.

These assumptions are very conservative, but they help a great deal in initial understanding of the method of solution. The assumptions yield a soil load on the pipe equal to the weight of the backfill soil above the pipe. This analysis provides an estimate of soil loads on the buried pipe if nothing else is known about the system.

The basic analysis developed by M.G. Spangler follows similar arguments to that given above. In this analysis, Spangler includes frictional forces between the trench wall and the backfill. This permits the weight of the overburden to be partially carried by the surrounding soil and reduces the total soil load on the pipe. The resulting equations for calculating the pipe load due to overburden are as follows:

C_d = \frac{1 – e^{(-2K_{\mu}(H_2/B))}}{2K_{\mu}}

C_d = \frac{1 - e^{(-2K_{\mu}(H_2/B))}}{2K_{\mu}}

- 𝐶𝑑 − Trench Coefficient

- 𝐵 − Trench Width(ft)

- 𝐻2 − Cover, vertical depth from the ground surface to top of pipe(ft)

- 𝐾𝜇 − Coefficient of friction force between the backfill soil and the trench wall.

Cd determines how much load is carried by the pipe. If there is no soil friction Cd becomes equal to H/B and the entire backfill load must be supported by the pipeline. The term Km provides a coefficient of friction force between the backfill soil and the trench wall. A high value of Km implies that friction between the backfill and trench wall is high and the weight of the backfill is supported largely by the wall friction. A low value implies that there is little friction encountered and the backfill is allowed to settle more such that the weight must be supported by the pipe. Table II provides values of Km used in the program for five different soil types. Also, in Table II are examples of values for Ds, the density which is the weight per unit of backfill, which may be used if an actual value is not known.

The soil types and coefficients given in this table represent the range that could normally be expected. Saturated clay has little internal friction so that it has the smallest value for Kμ. This implies that almost all of the soil load is carried by the pipe. Granular materials have a great deal more internal friction. Their value of Kμ is higher which leads us to the conclusion that the pipe carries less of the backfill load. Spangler, in his work, recommends using the value for clay in most instances. Higher values may be used when there is adequate evidence that the internal friction is higher and warrants a higher value of Kμ. Spangler’s recommendation provides a conservative estimate for common buried pipe situations. Marsh and bog areas, however, have friction properties more similar to saturated clay such that a value for Km equal to 0.110 should be used in these areas.

W_c = \frac{1 – e^{(-2K_{\mu}(H_2/B))}}{2K_{\mu}} D_s B^2(0.833)

W_c = \frac{1 - e^{(-2K_{\mu}(H_2/B))}}{2K_{\mu}} D_s B^2(0.833)

- 𝑊𝑐 − Load per unit Length of the Pipe due to Overburden(lbs/in)

- 𝐵 − Trench Width(ft)

- 𝐻2 − Cover, Vertical Depth from the Ground Surface to Top of Pipe(ft)

- 𝐷𝑠 − Density which is the Weight per unit of Backfill(lbs/ft3)

- 𝐾𝜇 − Coefficient of Friction Force between the Backfill Soil and the Trench Wall.

A Pavement Type must be determined in order to select an Impact Factor (I) to be used in the Wv equation. Table III provides Impact Factor values for the three different pavement types used in this program. A Pavement Type is also used to select the elastic constants for layered media analysis. The variables E1 & G1 will be used to represent the elastic constants for the top layer and E2 & G2 will be used to represent the elastic constants for the soil. See Figure 2 for a visual explanation of the elastic constants for the top layer and the soil. These values will also be used in the Wv equation. Table IV provides the values for the three different pavement materials used in this program.

W_v = \frac{0.0104L_wDI}{\pi \left( H_1 * \frac{1 [ft]}{12 [in]} + H_2 \right)^2} \left( \frac{E_1 G_1}{E_2 G_2} \right)^{-0.5 \left( \frac{H_1 * \frac{1 [ft]}{12 [in]}}{H_2} \right)^{0.7}}

W_v = \frac{0.0104L_wDI}{\pi \left( H_1 * \frac{1 [ft]}{12 [in]} + H_2 \right)^2} \left( \frac{E_1 G_1}{E_2 G_2} \right)^{-0.5 \left( \frac{H_1 * \frac{1 [ft]}{12 [in]}}{H_2} \right)^{0.7}}

- 𝑊𝑣 − Average Load per unit Length of the Pipe for Vehicular Load(lbs/in)

- 𝐷 − Outside Diameter of the Pipe(in)

- 𝐸1 − Modulus of Elasticity of the Top (timber or pavement)Layer(lbsin2⁄)

- 𝐸2 − Modulus of Elasticity of the Soil Cover(lbsin2⁄)

- 𝐺1 − Poisson′s Ratio of the Top (timber or pavement) Layer

- 𝐺2 − Poisson′s Ratio of Soil Cover

- 𝐷𝑠 − Density which is the Weight per unit of Backfill(lbs/ft3)

- 𝐻1 − Thickness of the Pavement Layer (“0” is used when there is no pavement) (in.)

- 𝐻2 − Cover,Vertical Depth from the Ground Surface to Top of Pipe(ft)

- 𝐷𝑠 − Density which is the Weight per unit of Backfill(lbs/ft3)

- 𝐼 − Impact Factor

- 𝐿𝑤 − Concentrated Surface Load (16000 lbs is recommended when the max.is unknown)(lbs)

Examination of equation Wv shows that this equation also may be used with a Single Layer System because the Pavement Material on the Top Layer chosen is “Soil”, which makes E1 equal to E2, G1 equal to G2, and H1 equal to zero which cancels out the second and third part of the equation. Thus, when there is no pavement layer the revised equation will provide a solution for soil cover only. Table IV provides the values for E1, E2, G1 & G2 that will be used in the program. Table IV

S_c = (W_c + W_v) \left( \frac{3 K_b E D T}{E T^3 + 3 K_z P D^3} \right)

S_c = (W_c + W_v) \left( \frac{3 K_b E D T}{E T^3 + 3 K_z P D^3} \right)

- 𝑆𝑐 − Circumferential Stress due to Pipe Wall Deflection(psi)

- 𝐷 − Outside Diameter of the Pipe(in)

- 𝐸 − Pipe Material Modulus of Elasticity (2.9×107)

- 𝐾𝑏 − Bending Coefficient which is a function of the crossing construction types

- 𝐾𝑧 − Deflection Coefficient which is a function of the crossing construction types

- 𝑃 − Pipe Internal Pressure (psi)

- 𝑇 − Pipe Wall Thickness(in)

- 𝑊𝑐 − Load per unit Length of Pipe due to Overburden(lbs/in)

- 𝑊𝑣 − Average Load per unit Length of Pipe for Vehicular Load (lbs/in)

Equation Sc, as well as equation St, have two constants which depend upon the bedding material upon which the pipe is placed. This bedding material is based on the crossing construction type. When the pipe is placed on a rigid bedding such as an Open Cut-Rock, little soil deformation occurs so that the load application area on the bottom is very small.

However, if the pipe is placed on soil, the support conforms to the pipe somewhat and the load is distributed over a larger area (See Figure 3). The latter case produces less pipe stress and is preferable. Spangler’s formulation includes both of these possibilities in order to provide a conservative estimate for the rigid bedding case without penalizing the soil bedding case. It does so by varying the constants Kb and Kz. Spangler’s recommended values for the constants are provided in Table V.

S_h=\frac{PD}{2T}

S_h=\frac{PD}{2T}- 𝑆ℎ − Hoop Stress due to Internal Pressure(psi)

- 𝐷 − Outside Diameter of the Pipe(in)

- 𝑃 − Pipe Internal Pressure(psi)

- 𝑇 − Pipe Wall Thickness(in)

S_t = \left( \frac{PD}{2T} \right) + \left( W_c + W_v \right) \left( \frac{3K_bEDT}{ET^3 + 3K_zPD^3} \right)

S_t = \left( \frac{PD}{2T} \right) + \left( W_c + W_v \right) \left( \frac{3K_bEDT}{ET^3 + 3K_zPD^3} \right)

The total circumferential stress (St) in a pipe wall is measured in PSI and is due to pressure (hoop) stress and bending stresses resulting from circumferential flexure caused by external loads. The equation for St is composed of two terms. The first term on the right-hand side of the equation is the formula for hoop stress due to internal pressure (Sh), while the second term is the formula for circumferential stress due to pipe wall deflection (Sc).

Longitudinal bending stress (Sb) occurs when the overburden and vehicle load on buried pipelines cause pipe settlement into the soil in the bottom of the trench. The settlement happens because soil is not as stiff as the pipe and will deform easily as the pipe is “pushed” downward. Under uniform soil conditions and overburden loading, the pipe will settle evenly into the trench bottom along its entire length. However, soil is generally not uniform, and regions of “softer” soil will occur adjacent to regions of stiff soil, causing uneven settling and bending of the pipe.

A load applied to only one portion of a pipeline will cause the section of pipe under the load to settle more than the unloaded pipe, resulting in bending. Longitudinal bending stress occurs in tension on the outside of the bend and in compression on the inside of the bend. A positive value for Sb represents tensile stress, while compressive stress takes a negative value. The calculation for longitudinal bending stress is as follows: S_b=\frac{EDY}{48X^2}

S_b=\frac{EDY}{48X^2}- 𝑆𝑏 − Longitudinal Bending Stress(psi)

- 𝐷 − Outside Diameter of the Pipe(in)

- 𝐸 − Pipe Material Modulus of Elasticity(2.9 x 107)

- 𝑋 − Longitudinal Distance over which Deflection occurs(ft)

- 𝑌 − Vertical Deflection(in)

A negative value will be used when calculating the total combined stress (S). This will result in a larger (more conservative) combined stress. Note: If longitudinal bending stress does occur, click onto the designated box next to “Longitudinal Bending Stress”. If the box is not marked, then the program will assume “0” for Sb.

S = \sqrt{(S_t^2 – S_tS_b + S_b^2)}

S = \sqrt{(S_t^2 - S_tS_b + S_b^2)}

- 𝑆 − Total Combined Stress by Von Mises(psi)

- 𝑆𝑏 − Longitudinal Bending Stress(psi)

- 𝑆𝑡 − Total Circumferential Flexure caused by External Loads(psi)

\%SMYS=\frac{S}{SMYS}

\%SMYS=\frac{S}{SMYS}- S – Total Combined Stress by Von Mises(psi)

- SMYS – Specified Minimum Yield Strength(psi)

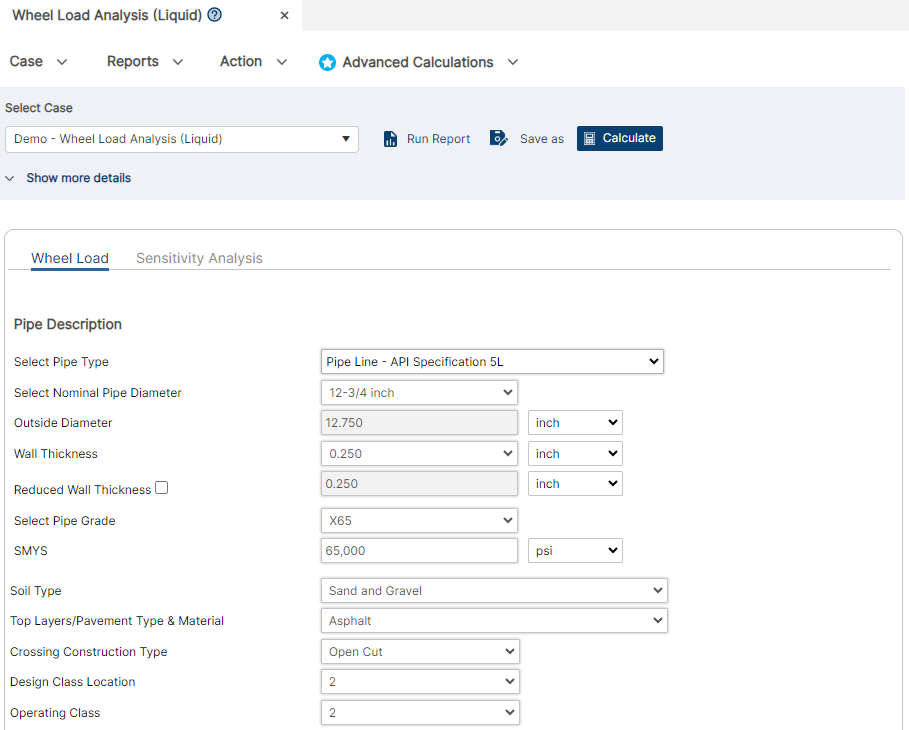

Case Guide

Part 1: Create Case

- Select the Wheel Load Analysis application from the Pipeline Crossing module

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required Parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

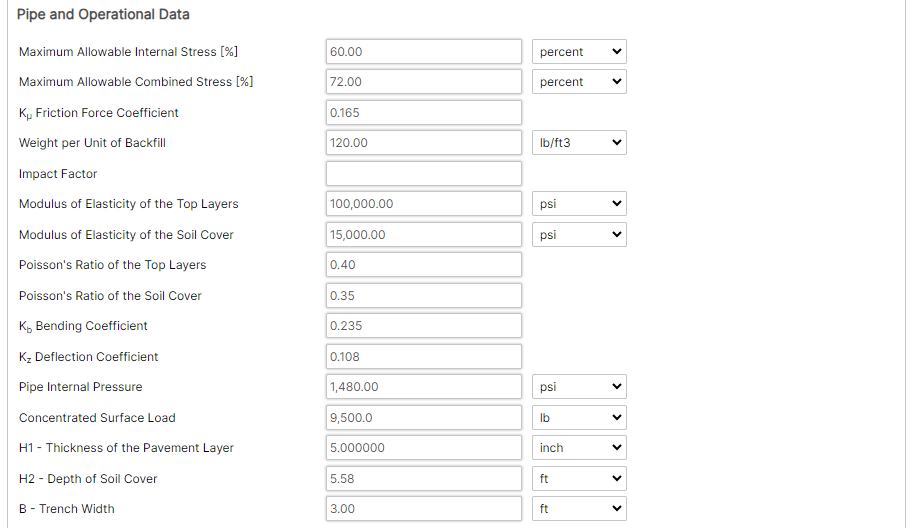

Input Parameters

- Potential Nominal Pipe Size(in):(1/8” – 48”)

- Pipe Outside Diameter(in):(0.625” – 48”)

- Pipe Wall Thickness(in):(0.068”- >2”)

- Design Location

- Operation Class

- Soil Type

- Top Layer/Pavement Type and Material

- Crossing Construction Type

- Maximum Allowable Internal Stress

- Maximum Allowable Combined Stress

- Friction Force Coefficient

- Weight Per Unit of Backfill

- Impact Factor

- Modulus of Elasticity of the Top Layer

- Modulus of Elasticity of the Soil Cover

- Poisson’s Ratio of the Top Cover

- Poisson’s Ratio of the Soil Cover

- Bending Coefficient

- Deflection Coefficient

- Pipe Internal Pressure

- Concentrated Surface Load

- Vertical Depth of the Soil Cover

- Thickness of the Pavement Layer

- Trench Width

- Specified Minimum Yield Stress:(24000psi-80000psi)

- Pipeline Length

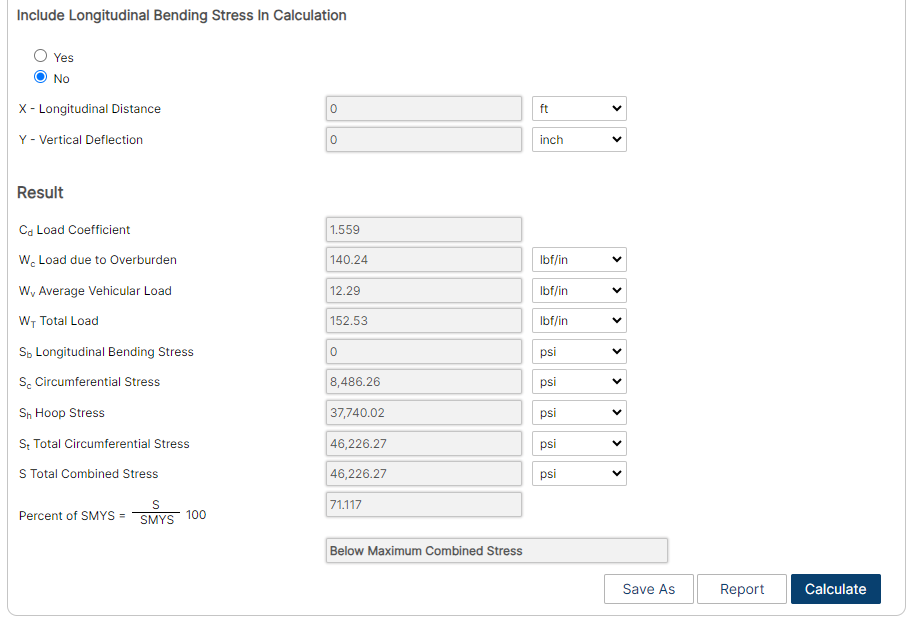

Part 2: Outputs/Report

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

Results

- Load Coefficient

- Load due to Overburden

- Average Vehicular Load

- Total Load

- Longitudinal Bending Stress

- Circumferential Stress

- Hoop Stress

- Total Circumferential Stress

- Total Combined Stress

- Percent Of SMYS

- Status

References

- Battelle Petroleum Technology Report on “Evaluation of Buried Pipe Encroachments” which considered the theoretical work done by M.G. Spangler on overburden and vehicle loads on buried pipe.

- “Technical Summary and Database for Guidelines for Pipelines Crossing Beneath Railroads and Highways” (GRI-91/0285, Final Report)

- Cornell/GRI Guidelines are given in “Guidelines for Pipelines Crossing Beneath Highways” (Stewart, et al., 1991b) and “Guidelines for Pipelines Crossing Beneath Highways”.

- ASME B31.8 “Gas Transmission and Distribution Systems” “Evaluation of Buried Pipe Encroachments”, BATTELLE, Petroleum Technology Center, 1983

- API RP 1102 – Steel Pipelines Crossing Railroads and Highways

FAQ

-

What are crossings – Live Load?

Many questions are asked about API 1102 regarding wheel load cyclic stresses on highways and railroads.

Live highway load, w, the load due to the wheel load at the highway surface. The load from only one wheel set needs to be considered. An axle is considered to have two-wheel sets.

Live rail load, w, pounds per sq inch, is the load applied at the surface of the crossing. It is assumed that the load is evenly distributed over an area that is 8’x 20’.The recommended default is 80,000 pounds (80 Kips) per axle. Check Out

-

Validation checks in place for API 1102 – Pipeline Crossing Railroad?

Below are the list of validation checks we have incorporated in API 1102 – Pipeline Crossing Railroad (Gas and Liquid). Check Out

-

Validation checks in place for API 1102 – Pipeline Crossing Highway?

Below are the list of validation checks we have incorporated in API 1102 – Pipeline Crossing Highway (Gas and Liquid). Check Out

-

Track Load – Interpolation Method (for Influence Coefficient)?

We recently issued an enhancement for Track load calculation by providing an option to use the Interpolation Method to calculate the Influence Coefficient (Ic). The old method calculated the Influence Coefficient using a roundoff method for ‘m-Influence Factor’ and ‘n-Influence Factor’ to get the Influence Coefficient from the table. Check Out

-

API 1102 Uncased Crossing 10 Foot Limit Understanding?

Uncased carrier pipe is subjected to internal loading from pressure and external loading from earth loading (dead load) and live (cyclic) loading from highway or railroad traffic. Other loading due to special or temporary conditions should be evaluated on the specific situation in the field (See Knowledge Base Article for Temporary Conditions). Check Out

-

Surface Load Mitigation Measures – Best Practice?

Method

Reduce the operating pressure of the pipeline.

Advantages

Provides a direct reduction of the hoop stress due to internal pressure. This reduction allows for additional circumferential stress due to equipment loads.

Disadvantages

– Reduces the beneficial effect of internal pressure on the pipe circumferential bending stresses due to fill and traffic loads.

– Could reduce the overall capacity of the pipeline and therefore should not be considered as a long term fix.

-

Difference between “Operating Weight” in Track Load Analysis and “concentrated surface load” in Wheel Load?

The term “Operating Weight” used in the track load analysis is a straight forward analysis as it takes the total weight of the equipment into consideration. We multiply the total weight by 0.5 to reflect the load on each track (see below the equation).

“Concentrated surface load” in the Wheel load calculation requires a more detailed understanding of the vehicle that is crossing. Below schematic will help better understand the requirement for “Concentrated surface load” entry in Wheel Load analysis.

-

Determining Trench Width for Crossings?

The basic analysis developed by M.G. Spangler includes frictional forces between the trench wall and the backfill. This permits the weight of the overburden to be partially carried by the surrounding soil and reduces the total soil load on the pipe. The equations require the following information to determine internal friction. Check Out

-

Combined Stress for Wheel Load and Track Load?

The question comes up from time to time how to address local stresses for wheel and track load calculations. ASME B31.8 833.9 Local Stresses states that the maximum allowable sum of circumferential stress due to internal pressure (Barlow Design Formula) and circumferential through-wall bending stress caused by surface vehicle loads or other local loads is 0.9ST, where S is the specified minimum yield strength, psi (MPA) per para. 841.1 (a), and T is the temperature derating factor per para. 841.1.8. Check Out

-

What Are Timber Mats in Crossing?

Timber mats are used for temporary access roads, work pads, staging areas, and to stabilize the ground beneath heavy equipment, dissipating heavy loads and providing equipment stability.

For short-term water crossings over narrow spans timber mats (also referred to as bridge mats) or crane mats may be an option.

For projects that require moving heavy equipment safely across pipelines, timber mats can be used to create air bridges which will support the weight of heavy equipment while protecting the pipelines below. Air bridges can also be used to cross culverts, ditches, or sensitive ground that needs to be bridged. Check Out

-

Redistributing Wheel and Track Loads (Pavement and Other Materials)?

This knowledge base article is a takeoff from “Pipeline Toolbox (PLTB) and Vehicles over Buried Pipelines – Maximum Allowable Stress”. These predictions through Spangler’s work, Battelle and others who contributed to validation makes PLTB one of most used programs in the industry. It includes temporary wheel and track load crossings that considers a uniformly distributed load at the surface while calculating the load on the pipe. This article will focus on concrete, asphalt and timber mats as well as other materials such as steel plates and composites. The other materials are not part of the Pipeline Toolbox which will be discussed. Check Out

-

Pipeline Crossings – External Loads and Vehicles over Buried Pipelines “Maximum Allowable Combined Stress”?

This article was created due to the number of inquiries regarding the Maximum Allowable Combined Stress for Class 3 Design Areas. The research by M. G. Spangler, Battelle and industry allowed this information to be a standard practice today with Wheel and Track Load analysis today. Check Out

-

Applicability of Class Location for Liquid Lines? What is the design factor used for Liquid Pipeline Operation?

Design factor specification for Liquid Pipelines are governed by ASME B31.4 Table 402.3.1(a)

Excerpts from B31.4: Check Out

-

Loading Requirements for API 1102 E-80 and E-90 Railroad Crossings?

API 1102 for railroad crossing program is based on the design methodology that has been used in analyzing existing uncased pipelines and designing new uncased pipelines that cross beneath railroads. This API design methodology relates to the train engine (E-80) which is the heaviest load: Check Out

-

What are Cased Crossings?

The pipeline industry begins to experience casing problems such as carrier pipe leaks/failures under road crossings.

- Atmospheric corrosion due to condensation (particularly at elevated temperatures and cold soils)

- Metal to metal shorts

- Electrolytic coupling or contact

Can the casing pipe protect the carrier pipe from external loadings? Check Out

-

Understanding Impact Factors in Pipeline Design (CEPA)

What is an Impact Factor?

An impact factor is a multiplier used in pipeline design to account for the additional stress caused by moving vehicles above the pipeline, compared to static loads. Think of it as a “safety buffer” that accounts for the dynamic nature of traffic. Check Out