HDDPT Drilling Fluids/Mud Management

Drilling Fluid Quantity Requirements

Calculating drilling-fluid quantity estimates that will be used during an HDD installation are important in determining the impact of drilling activities. Calculation of quantities consumed is performed by considering each phase of the HDD while Drilling Fluid Consumed making certain assumptions. Equations for calculating estimated drilling fluid/slurry quantities are provided below.

Pit Hole – Drilling Fluid Consumed:

Qp = Drilling Fluid Flow Rate (bbl/min)

L = Total Drill Length (ft)

Prate = Pilot Hole Production Rate (ft/hr)

fpump = Pumping Factor (min/hr)

fpilot = Circulation Loss Factor

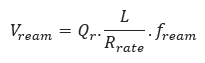

Prereaming – Drilling Fluid Consumed:

Qr = Drilling Fluid Flow Rate (bbl/min)

Rrate =Prereaming Penetration Rate (ft/min)

fream = Circulation Loss Factor

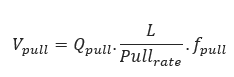

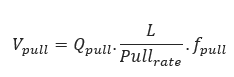

Pulling Back – Drilling Fluid Consumed:

Qpull = Drilling Fluid Flow Rate (bbl/min)

Pullrate = Prereaming Penetration Rate (ft/min)

fpull = Circulation Loss Factor

Total Drilling Fluid Consumed:

𝑓𝑙𝑢𝑖𝑑𝑐𝑜𝑛𝑠𝑢𝑚𝑒𝑑 = (𝑉𝑝𝑖𝑙𝑜𝑡 + 𝑉𝑟𝑒𝑎𝑚 + 𝑉𝑝𝑢𝑙𝑙)

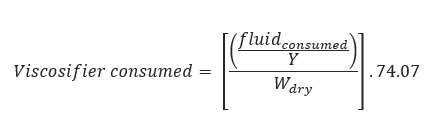

Viscosifier Consumed:

Y = Viscosifier Yield (bbl/ton)

Wdry = Viscosifier Dry Weight (lb/ft3)

Water Consumed:

Water Consumed = Total Drilling Fluid Consumed

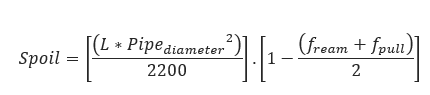

Drilled Spoil:

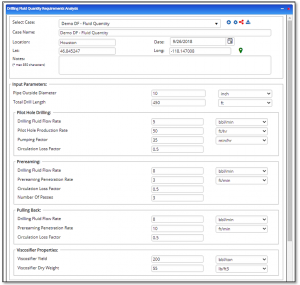

Input Parameters

- Pipe Outside Diameter (inch)

- Total Drill Length (ft)

Pilot Hole Drilling:

- Drilling Fluid Flow Rate (bbl/min)

- Pilot Hole Production Rate (ft/hr)

- Pumping Factor (min/hr)

- Circulation Loss Factor

Prereaming:

- Drilling Fluid Flow Rate (bbl/min)

- Prereaming Penetration Rate (ft/min)

- Circulation Loss Factor

- Number of Passes

Pulling Back:

- Drilling Fluid Flow Rate (bbl/min)

- Prereaming Penetration Rate (ft/min)

- Circulation Loss Factor

Viscosifier Properties:

- Viscosifier Yield (bbl/ton)

- Viscosifier Dry Weight (lb/ft3)

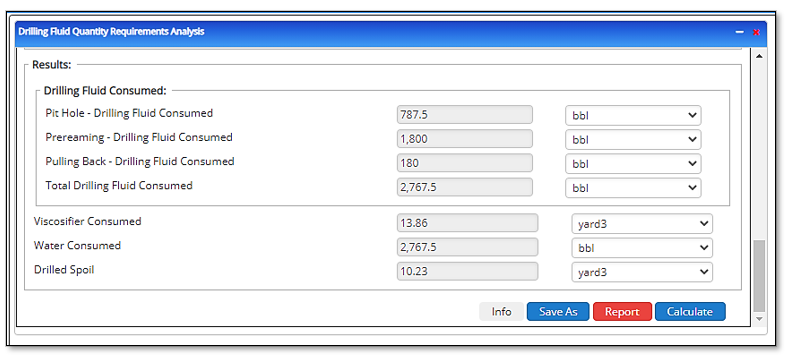

Outputs/Reports

Drilling Fluid Consumed:

- Pit Hole – Drilling Fluid Consumed (bbl)

- Prereaming – Drilling Fluid Consumed (bbl)

- Pulling Back – Drilling Fluid Consumed (bbl)

- Total Drilling Fluid Consumed (bbl)

- Viscosifier Consumed (yard3)

- Water Consumed (bbl)

- Drilled Spoil (yard3)

References

- AGA/PRCI Report PR-227-9321 (Catalog Number L51725)

- Willoughby, David (2005). Horizontal Directional Drilling, McGraw-Hill, New York, ISBN 0-87814-395-5. v

Appendix: Definitions

AUGER BORING – Casing is jacked into the ground as a rotating auger works simultaneously to remove the excavated soil. It is commonly used in applications where settlement is a concern: under highways, railways and levies. Also known as a dry bore.

BENTONITE – A natural clay material used as a basic ingredient for drilling muds and lubricants to facilitate ease of installation.

BORE OR BOREHOLE – drilling term – The elongated cavity created by the drilling process. Often the borehole is not a void, but rather a hole filled with drilling mud and cuttings. Well casing is pulled or pushed into the borehole to complete a well.

CASING – drilling term – The non-perforated or non-slotted pipe that comprises the entry and exit sections of a horizontal well, as opposed to the well screen. Surface casing is a pipe that is set through loose surficial deposits to stabilize the bore, so the deeper sections can be drilled without difficulty from caving or collapse in the upper section of the borehole.

CROSSING – A pipeline installation designed to pass beneath a surface obstruction. Examples of crossings include roads, railway tracks, water bodies, pipeline corridors, and utilities.

DRILLING MUD – drilling material – aqueous slurry that is used during drilling to transport drill cuttings from the borehole, prevent borehole collapse and provide lubrication for the drill string. Most horizontal drilling uses drilling mud of some sort, although in some conditions it is possible or preferable to drill using air or water. Drilling mud made be made using the mineral bentonite, synthetic or natural polymers, or some combination of the two.

DRILL RIG – A trenchless machine that installs pipes and cables by drilling a pilot hole that can be enlarged (if necessary), and then pulling the product line.

ENTRY POINT – The starting location of the crossing where the drill enters the ground.

EXIT POINT – The end location of the crossing.

FORWARD REAMER – drilling tool – A type of reamer used to enlarge the diameter of the borehole in a blind or single-entry well.

HORIZONTAL DIRECTIONAL DRILLING (HDD) – A surface-based trenchless technology that involves a horizontal bore under the surface along a planned pathway. Once the HDD creates a bore of a suitable size – which may require one or multiple passes by the drilling apparatus – the conduit or pipe is pulled into the bore and connections are made to the appropriate utilities.

OPEN CUT – Underground construction method involving excavation from ground level to the level required for the installation, maintenance, or inspection of a pipe, conduit, or cable. Upon completion of the work, the trench is backfilled and the surface restored. Backhoe excavation is an example of open-cut construction.

PILOT BORE – drilling term – The initial boring made in a horizontal well installation. The pilot bore is steered, using any of several technologies, from a designated entry point, along a predetermined bore path, to a designated endpoint, either at the ground surface or at depth. The pilot bore subsequently may be reamed to a larger diameter to accommodate the desired size well screen and casing.

PIPE PULLING – Method used to replace small diameter pipes by attaching new product pipe to the existing pipe, which is then pulled out of the ground.

POTHOLE – drilling term – a small hole excavated from the surface to a buried utility in order to provide positive verification of its location.

REAMER – drilling tool – a cutting tool used to enlarge the diameter of a borehole after the pilot bore has been drilled.

VISCOSIFIER – thickener -is a type of rheology modifier that can be used to increase the viscosity of a system. Additional benefits of increasing viscosity are improved suspension of solids and emulsion stability.