ASME B31G Evaluation of MAOP in Corroded Areas

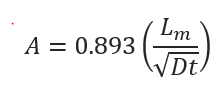

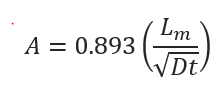

Computation of A

If the measured maximum depth of the corroded area is greater than 10 % of the nominal wall thickness, and the measured longitudinal extent of the corroded area is greater than the value determined by Equation (2), calculate:

where

𝐴 − intermediate factor A

𝐿𝑚 − measured longitudinal extent of the corroded area(in)

𝐷 − nominal outside diameter of the pipe(in)

𝑡 − nominal wall thickness of the pipe(in)

Additional wall thickness required for concurrent external loads shall not be included in calculation.

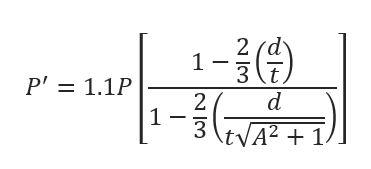

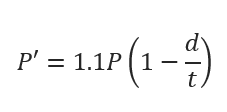

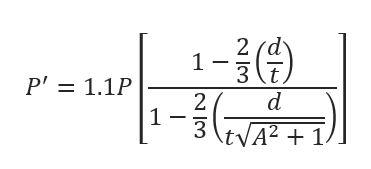

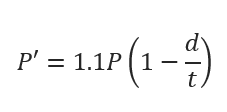

Computation of P’

(a) For values of Less Than or Equal to 4.0.

Where

𝑃’− the safe maximum pressure for the corroded area

𝑑− measured maximum depth of corroded area(in)

𝐷− nominal outside diameter of the pipe(in). May not exceed P.

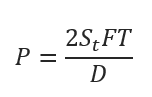

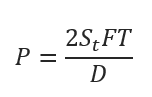

Ρ – the greater of either the established MAOP or

Where

𝑆− specified minimum yield strength ,SMYS.(𝑝𝑠𝑖)

𝐹− appropriate design factor from ASME B31.4, ASMEB31.8, or ASME B31.11

𝑇− temperature derating factor from the appropriate B31 Code ,if not listed, T = 1.

𝐷− nominal outside diamerter of pipe(in)

𝑡 − nominal wall thickness of the pipe(in)

Additional wall thickness required for concurrent external loads shall not be included in the calculations.

MAOP and P’

If the established MAOP is equal to or less than, the corroded region may be used for service at that MAOP. If the established MAOP is greater than, then a lower MAOP should be established not to exceed, or the corroded region should be repaired or replaced.

where

𝐴 − intermediate factor A

𝐿𝑚 − measured longitudinal extent of the corroded area(in)

𝐷 − nominal outside diameter of the pipe(in)

𝑡 − nominal wall thickness of the pipe(in)

Additional wall thickness required for concurrent external loads shall not be included in calculation.

Computation of P’

(a) For values of Less Than or Equal to 4.0.

Where

𝑃’− the safe maximum pressure for the corroded area

𝑑− measured maximum depth of corroded area(in)

𝐷− nominal outside diameter of the pipe(in). May not exceed P.

Ρ – the greater of either the established MAOP or

Where

𝑆− specified minimum yield strength ,SMYS.(𝑝𝑠𝑖)

𝐹− appropriate design factor from ASME B31.4, ASMEB31.8, or ASME B31.11

𝑇− temperature derating factor from the appropriate B31 Code ,if not listed, T = 1.

𝐷− nominal outside diamerter of pipe(in)

𝑡 − nominal wall thickness of the pipe(in)

Additional wall thickness required for concurrent external loads shall not be included in the calculations.

(b) For Value of a Than 4.0.

MAOP and P’

If the established MAOP is equal to or less than, the corroded region may be used for service at that MAOP. If the established MAOP is greater than, then a lower MAOP should be established not to exceed, or the corroded region should be repaired or replaced.

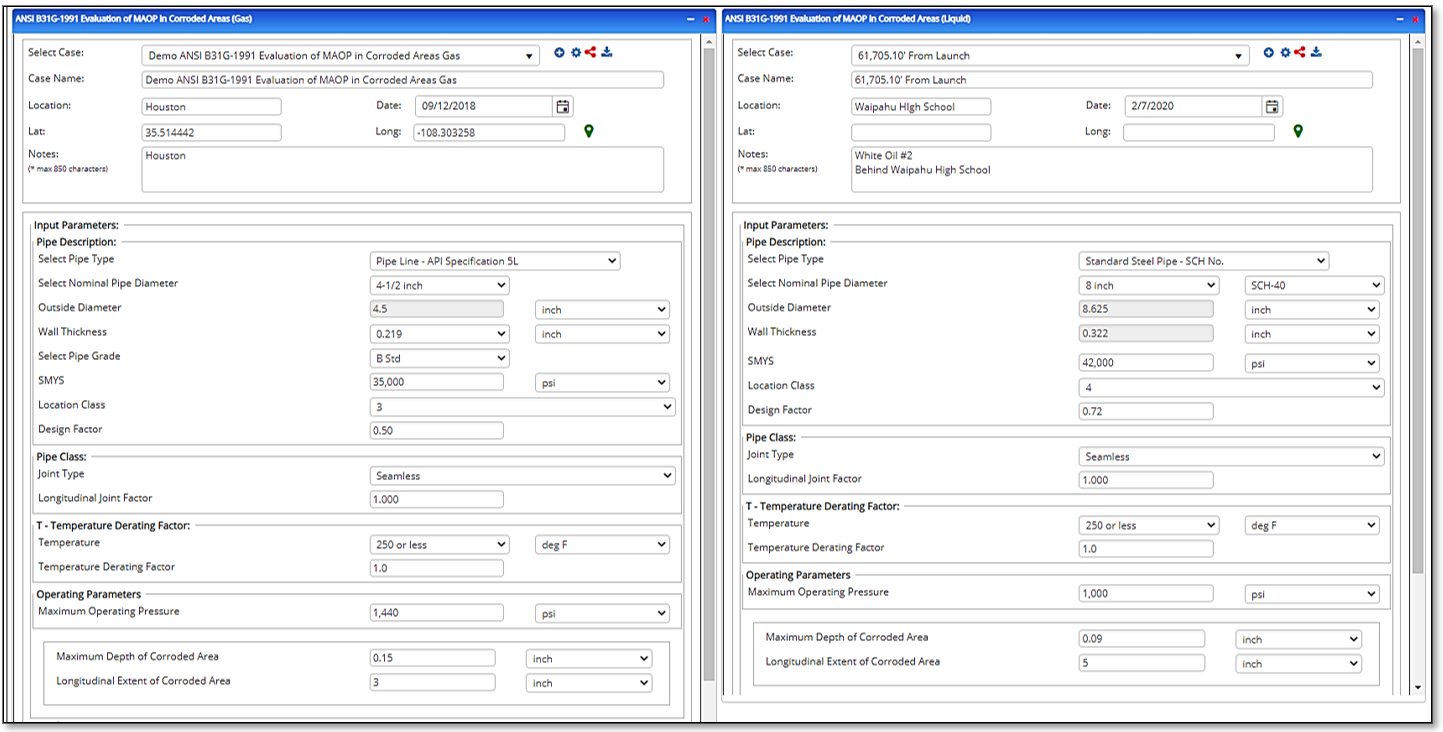

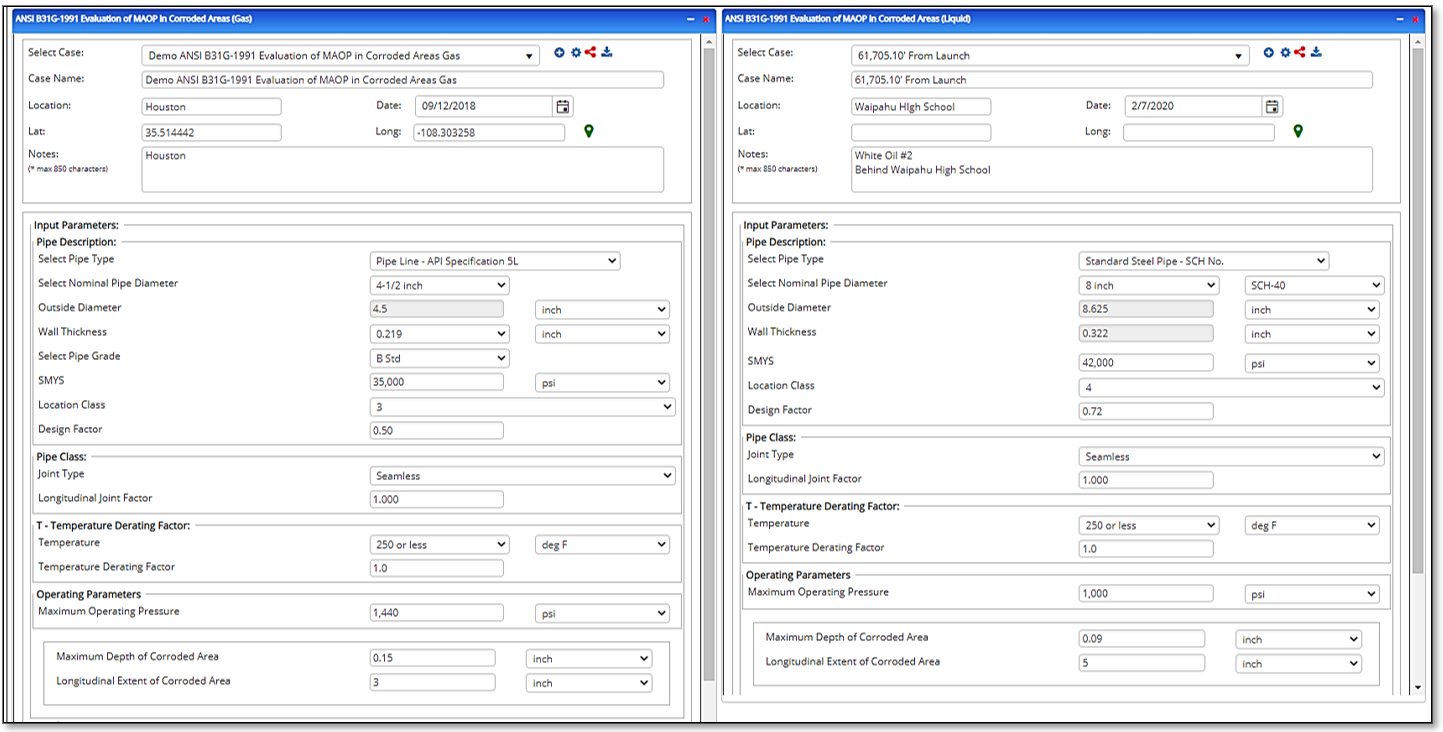

Input Parameters

- To create a new case, click the “Add Case” button

- Select the ANSI B31G-1991 Evaluation of MAOP in Corroded Areas application from the Pipeline Corrosion list.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button.

- Wall Thickness(in)

- Pipe Grade

- Design Factor – F

- Longitudinal Joint Factor – E

- Temperature Derating Factor – T

- Maximum Depth of Corroded Area

- Longitudinal Extent of Corroded Area

- Pipe Outside Diameter(in)

- Specified Minimum Yield Strength – SMYS

- Maximum Operating Pressure – MOP (psi)

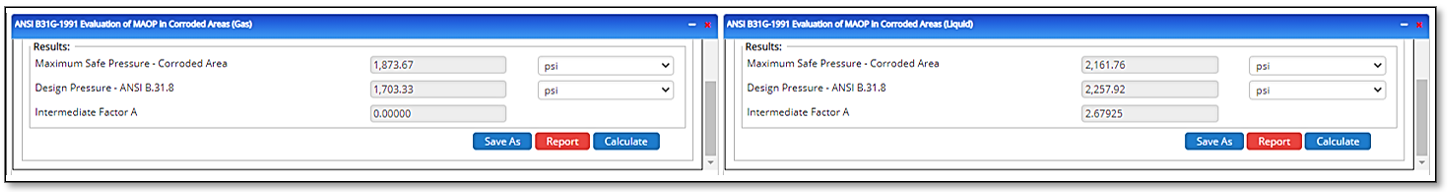

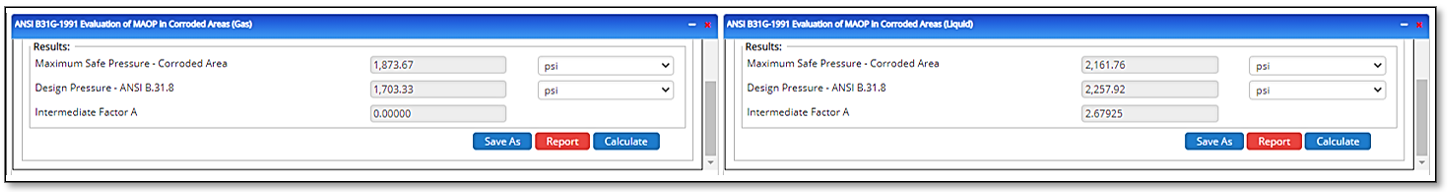

Outputs/Reports

- View the results.

- If an input parameter needs to be edited be sure to hit the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon.

- To delete a case, click the DELETE icon near the top of the widget.

- Maximum Safe Pressure(psi)

- Design Pressure – ANSI B.31.8(psi)

- Intermediate Factor A