ASME B31G

Introduction

Texas Eastern Transmission Corporation and the AGA Pipeline Research Committee conducted research in the late 1960’s and early 1970’s that resulted in the development of a criterion to evaluate the serviceability of corroded pipe. This research was performed at the Columbus laboratories of Battelle Memorial Institute. This criterion has been included in both the B31.4 and B31.8 design codes and is described in detail in the document, “ANSI/ASME B31G -1984 Manual for Determining the Remaining Strength of Corroded Pipelines”.

Research Objective:

- To examine fracture initiation behavior as a function of corrosion defect size and internal pressure that would cause a leak or rupture.

- To search with an understanding that a corrosion defect:

- Is caused by an electrochemical process by which the iron in refined steel returns to a more stable state

- Results in metal loss at anodic areas

- Is not uniform and homogenous

Does not involve mechanical stress - Was formed by a ‘stress free’ process

- It is for these reasons that ASME B31G and the Modified Criterion, RSTRENG, are not recommended for application to dents, dings or gouges.

The Making of ANSI/ASME B31G

In response to the increasing need for methodology that would predict the lowest pressure that would cause a corroded pipe area to fail, Texas Eastern Transmission Corporation and the AGA Pipeline Research Committee conducted research performed at the Columbus laboratories of Battelle Memorial Institute in the late 1960’s and 1970’s.

In response to the increasing need for methodology that would predict the lowest pressure that would cause a corroded pipe area to fail, Texas Eastern Transmission Corporation and the AGA Pipeline Research Committee conducted research performed at the Columbus laboratories of Battelle Memorial Institute in the late 1960’s and 1970’s.- The research resulted in the development of early criterion described in the initial 1984 Edition.

- The 84 edition pictured right:

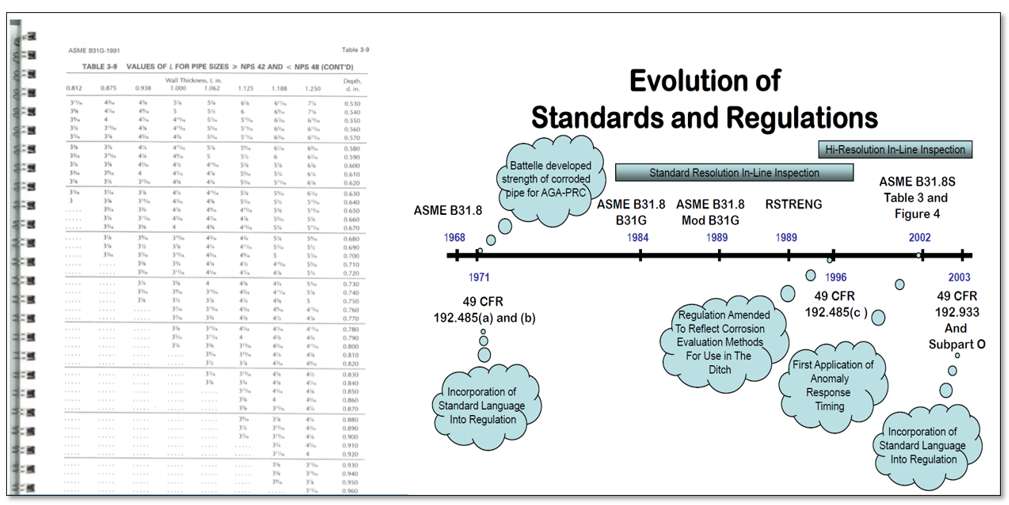

Evolution of Standards & Regulations