Basic Equation for Hoop Failure Stress

Understanding Basic Equation for Hoop Failure Stress

- Used to calculate the failure stress level of a pressurized pipe containing a longitudinally oriented crack or defect. The length is taken as L, along the pipe axis, even if the corrosion pits are not lined up along the pipe axis.

- Developed on the basis of rather sharp flaws, whereas corrosion usually produces rather blunt defects. These two factors tend to add conservatism to the analysis.

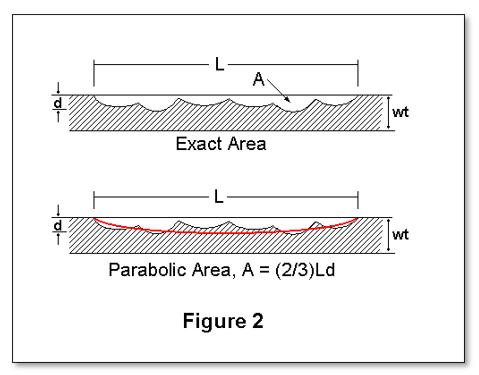

Figure 1 shows an example of how corrosion might occur and the parameters of metal loss used in the RSTRENG analysis.

- L is the axial length of corrosion

- d is the maximum depth of corrosion

- wt is the pipe wall thickness

- A is the corrosion profile area projected into the axial plane

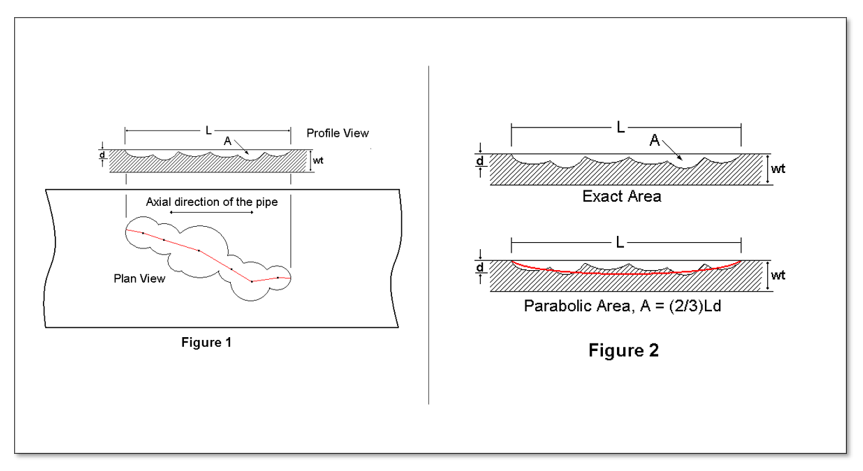

Figure 2 shows how the corrosion area, A, is defined as a parabola for the B31G Criterion.

Values of the Equation Factors were established by Committee Consensus

- “M” was defined as (1 + .8L2/Dt).5

- “S” the flow stress was assumed to be 1.1 x SMYS

- To simplify the analysis of the area of metal loss, “A” was defined to be the area of a parabola that presumed the deepest pit was exactly in the middle of the projected length of corrosion. The metal loss then becomes A = (2/3)Ld

- A0 is the corrosion length times full wall thickness (Lt)

Figure 2 below shows how the area of projected metal loss A, is defined as a parabola for the initial B31G Criterion.