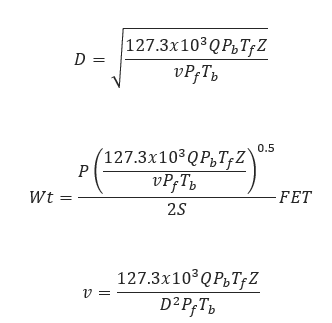

Compressor Station Piping - Pipe Diameter, Wall Thickness and Gas Velocity

This application uses gas velocity and flow rates to determine the minimum required pipe diameter for station piping.

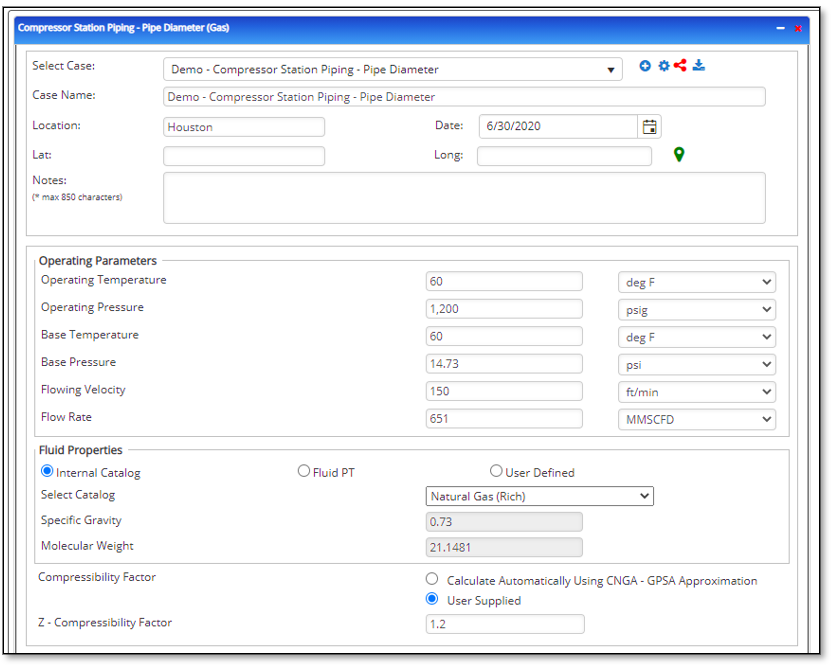

𝑣 − Gas Velocity[ft/min]

𝑄 − Flow Rate[MMCFD]

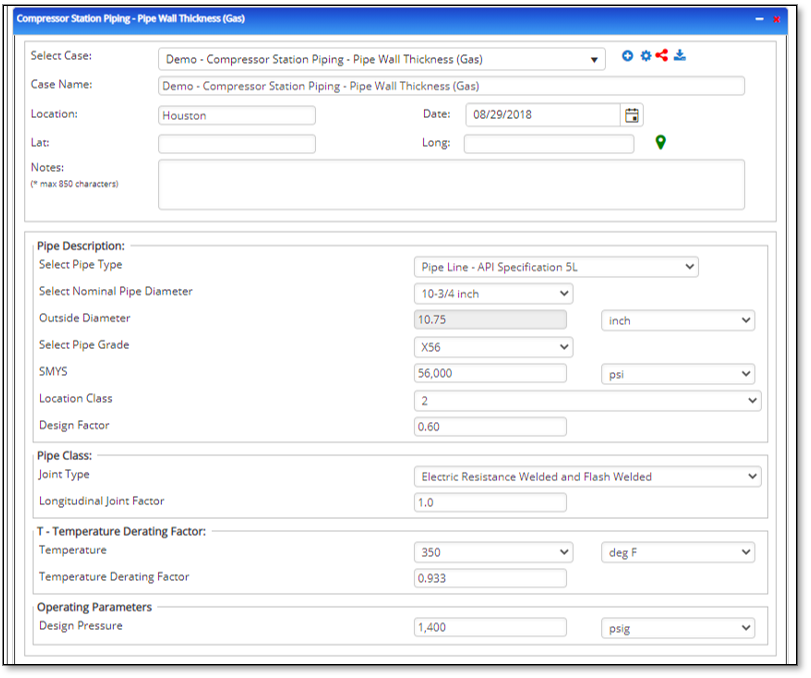

𝑊𝑡 − Wall Thickness[in]

𝑃 − Design Pressure[psi]

𝐹 − Design Factor

𝐸 − Longitudinal Joint Factor

𝑇 −Temperature Derating Factor

𝑃𝑏 − Base Pressure[psia]

𝑇𝑓 − Flowing Temperature[°R]

𝑍 − Compressibility Factor

𝐷 − Internal Pipe Diameter[in]

𝑃𝑓− Flowing Pressure[psia]

𝑇𝑏 − Base Temperature[°R]

Note: Gas velocity in piping should not exceed 2000(ft/min)

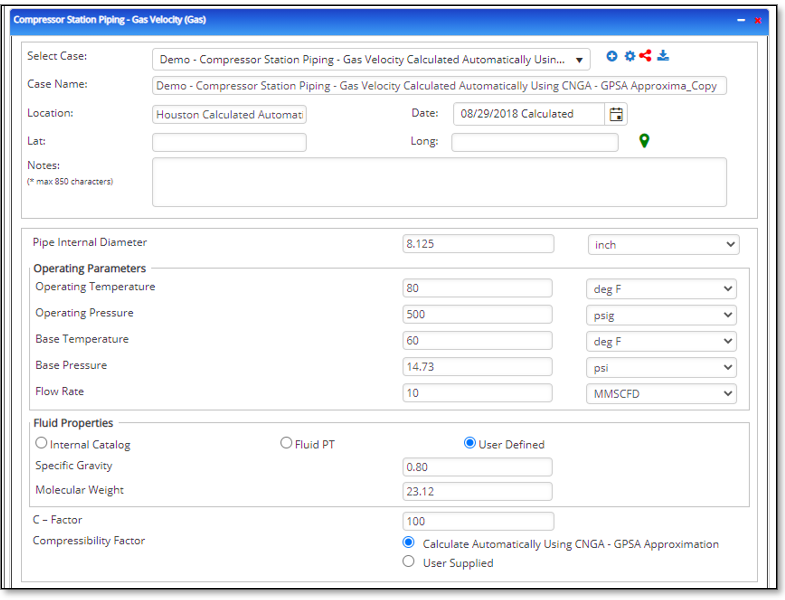

Input Parameters

- To create a new case, click the “Add Case” button

- Select the Compressor Station Piping – Pipe Diameter, Wall Thickness and Gas Velocity application from the Pipeline Compressor module.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button.

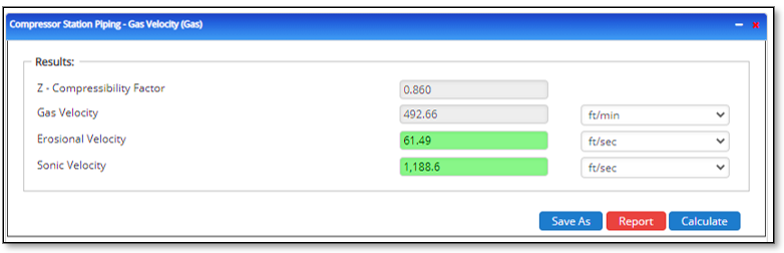

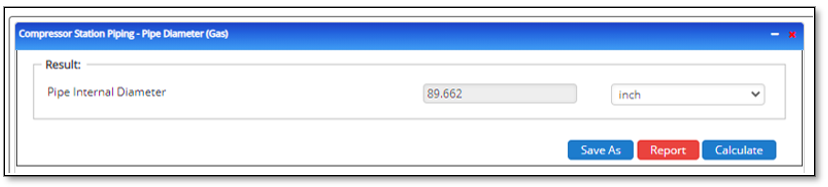

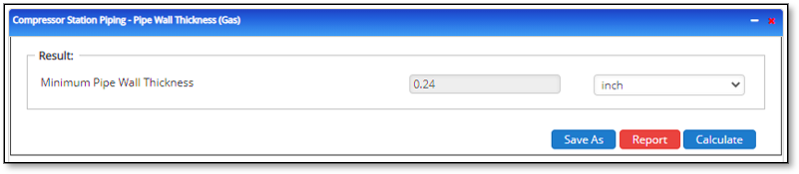

Outputs/Reports

- View the results.

- If an input parameter needs to be edited be sure to hit the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon.

- To delete a case, click the DELETE icon near the top of the widget.

Pipe Diameter

Pipe Wall Thickness

Gas Velocity