Reciprocating Compressor - Cylinder/Equivalent Capability & Horsepower

This application uses a positive displacement compressor model to deliver gases at high pressures. With piston displacement reciprocating compressors, often final outlet temp could be a concern.

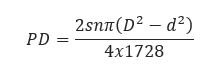

Piston Displacement

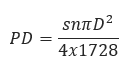

Single-Acting Piston Compression on the Outer End Only:

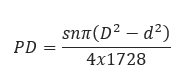

Single-Acting Piston Compression on the Crank End Only:

Double-Acting Piston Compression (Other than Tail Rod Type):

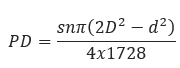

Double-Acting Piston Compression (With a Tail Rod):

𝑃𝐷 − Piston Displacement[ft3/min]

𝑠 – Stroke[𝑖𝑛]

𝑛 − Rotational Speed[rpm]

𝐷 − Cylinder Inside Diameter[in]

𝑑 − Piston Rod Diameter [in]

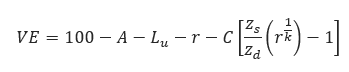

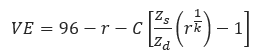

Reciprocating Compressor Volumetric Efficiency

𝑉𝐸−Volumetric Efficiency[%]

𝐴 − Effect of Leakage, Losses, etc.[%]

𝐿𝑢 − Effect due to Lack of Lubrication[%]

𝑟 − Compression Ratio[𝑃2/𝑃1]

𝐶−Cylinder Clearance as a Percent of Cylinder Volume[%]

𝑧𝑠 − Compressibility Factor at Suction Conditions

𝑧𝑑 − Compressibility Factor at Discharge Conditions

𝑘 − Adiabatic/Isentropic Exponent[𝑐𝑝/𝑐𝑣]

In practice for normal operation

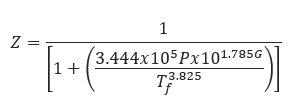

CNGA/GPSA Compressibility Factor Approximation

𝑍 − Compressibility Factor

𝑃 − Pressure(psi)

𝑇𝑓 − Gas Flowing Temperature[°𝑅]

This approximation will produce results sufficiently accurate for preliminary calculations.

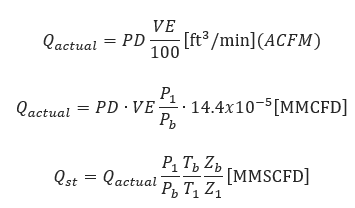

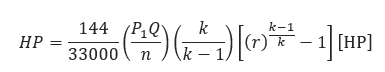

Reciprocating Compressor Horsepower

𝑄 − Suction Capacity[SCFM]

𝑃1 − Gas Suction Pressure(psi)

𝑛 − Compressor Efficiency

𝑘 =  −Specific Heat Ratio

−Specific Heat Ratio

𝑟 − Compression Ratio [𝑃2/𝑃1]

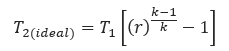

Ideal Discharge Temperature

𝑇2(𝑖𝑑𝑒𝑎𝑙) − Ideal Discharge Temperature[°R]

𝑇1 − Suction Temperature[°R]

𝑟 − Compression Ratio [P2/P1]

𝑘 − 𝐴diabatic/Isentropic Exponent

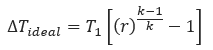

Theoretical Discharge Temperature

𝑇2 = 𝑇1 + ∆𝑇𝑖𝑑𝑒𝑎𝑙

𝑇2 − Theoretical Discharge Temperature[°R]

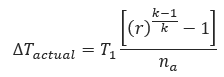

Actual Discharge Temperature

𝑇2 = 𝑇1 + ∆𝑇𝑎𝑐𝑡𝑢𝑎𝑙

𝑇2 − Actual Discharge Temperature[°R]

𝑛𝑎 − Adiabatic (Isentropic)Efficiency

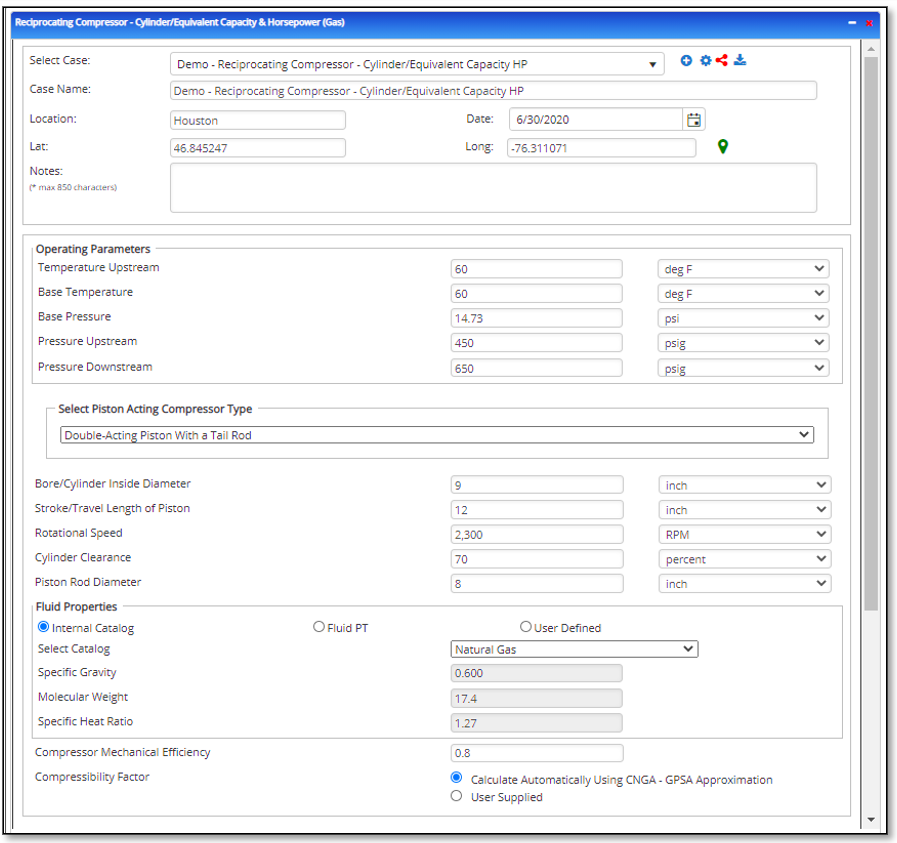

Input Parameters

- To create a new case, click the “Add Case” button

- Select the Reciprocating Compressor – Cylinder/Equivalent Capability & Horsepower application from the Pipeline Compressor module.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button.

- Base Pressure(psi)

- Base Temperature(°F)

- Select Piston Acting Compressor Type

- Bore/Cylinder Inside Diameter(in)

- Stroke/Travel Length of Piston(in)

- Rotational Speed(rpm)

- Cylinder Clearance (%)

- Piston Rod Diameter(in)

- Suction Pressure(psi)

- Suction Temperature(°F)

- Discharge Pressure(psi)

- Gas Specific Heat Ratio

- Gas Specific Gravity (Relative to air)

- Compressor Mechanical Efficiency (0.95 – 0.98)

- Z1 – Compressibility Factor at Suction Conditions

- Z2 – Compressibility Factor at Discharge Conditions

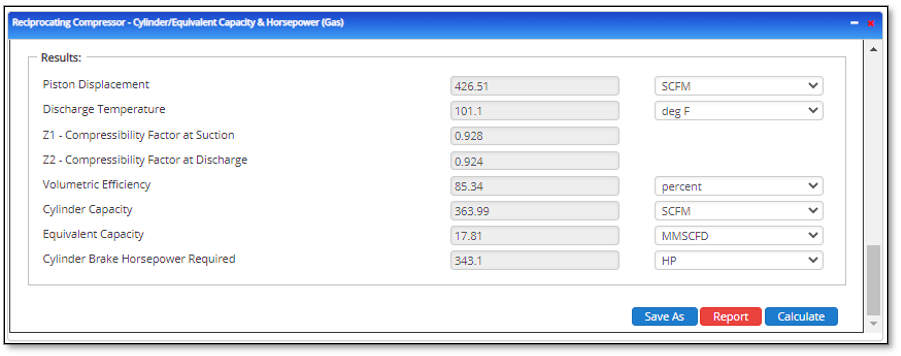

Outputs/Reports

- View the results.

- If an input parameter needs to be edited be sure to hit the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon.

- To delete a case, click the DELETE icon near the top of the widget.

- Piston Displacement(ft³/min)

- Discharge Temperature(°F)

- Z1 – Compressibility Factor at Suction

- Z2 – Compressibility Factor at Discharge

- Volumetric Efficiency (%)

- Cylinder Capacity(ft³/min)

- Equivalent Capacity(MMSCFD)

- Cylinder Brake Horsepower Required(HP)