Bending Stress and Deflection

This application is related bending stresses and deflection on a uniformly loaded span. The weight of the pipe and product.

If there is more than one loading, superimposing individual solutions will be required. To account for unknow stresses multiply the longitudinal stress by 1.1.

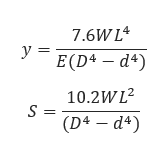

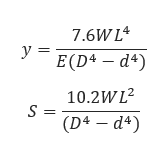

Fixed End Supports:

𝑦 − Maximum Deflection(ft)

𝑆 − Maximum Bending Stress(psi)

𝑊 − Unit Weight(lbf)

𝐿 − Length(ft)

𝐸 − Modulus of Elasticity(psi) (𝑆𝑡𝑒𝑒𝑙=30,000,000, 𝑝𝑙𝑎𝑠𝑡𝑖𝑐,𝑑𝑢𝑝𝑜𝑛𝑡.=100,000, 𝑝𝑙𝑎𝑠𝑡𝑖𝑐,𝑝𝑙𝑒𝑥𝑐𝑜.=125,000, 𝑐𝑎𝑠𝑡 𝑖𝑟𝑜𝑛=15,000,000, 𝑐𝑜𝑝𝑝𝑒𝑟=15,000,000)

𝐷 − Outside Diameter(in)

𝑑 − Inside Diameter(in)

Simple Supports:

𝑦 = 5 times 𝑦 for fixed ends

𝑆 = 1.5 times 𝑆 for fixed ends

Cantilever Support:

𝑦 = 48 times 𝑦 for fixed ends

𝑆 = 6 times 𝑆 for fixed ends

𝑆 and 𝑦 on the schematics indicate the points od MAXIMUM stress deflection.

Fixed End Supports:

𝑦 − Maximum Deflection(ft)

𝑆 − Maximum Bending Stress(psi)

𝑊 − Unit Weight(lbf)

𝐿 − Length(ft)

𝐸 − Modulus of Elasticity(psi) (𝑆𝑡𝑒𝑒𝑙=30,000,000, 𝑝𝑙𝑎𝑠𝑡𝑖𝑐,𝑑𝑢𝑝𝑜𝑛𝑡.=100,000, 𝑝𝑙𝑎𝑠𝑡𝑖𝑐,𝑝𝑙𝑒𝑥𝑐𝑜.=125,000, 𝑐𝑎𝑠𝑡 𝑖𝑟𝑜𝑛=15,000,000, 𝑐𝑜𝑝𝑝𝑒𝑟=15,000,000)

𝐷 − Outside Diameter(in)

𝑑 − Inside Diameter(in)

Simple Supports:

𝑦 = 5 times 𝑦 for fixed ends

𝑆 = 1.5 times 𝑆 for fixed ends

Cantilever Support:

𝑦 = 48 times 𝑦 for fixed ends

𝑆 = 6 times 𝑆 for fixed ends

𝑆 and 𝑦 on the schematics indicate the points od MAXIMUM stress deflection.

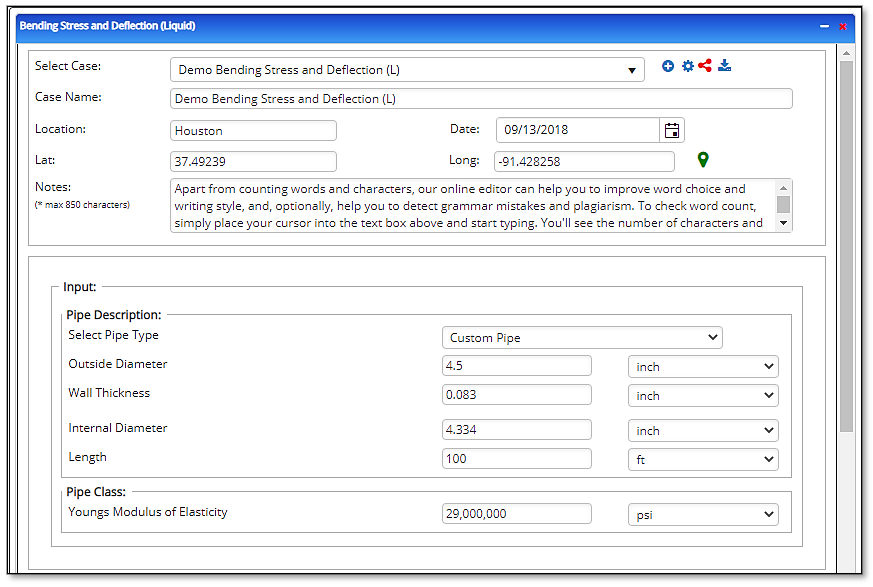

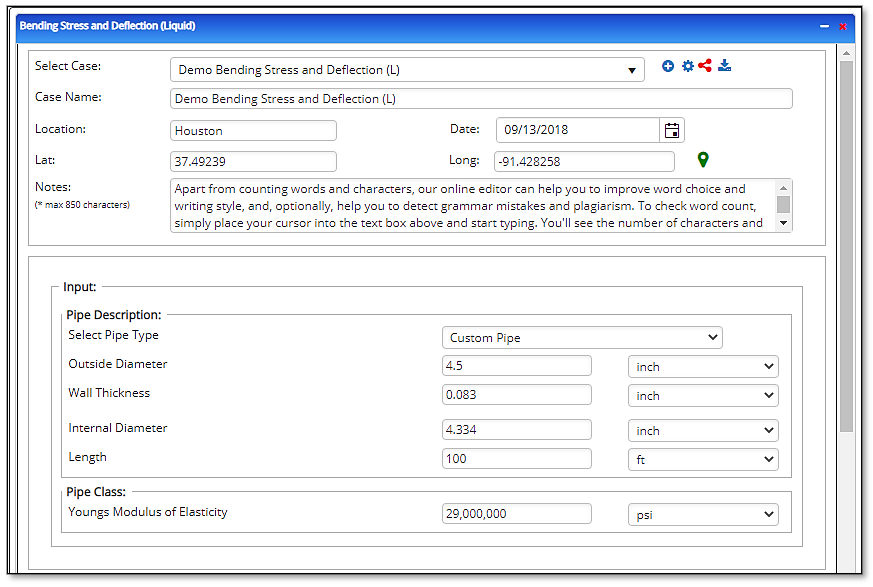

Input Parameters

- To create a new case, click the “Add Case” button

- Select the Bending Stress and Deflection application from the Steel Pipe – Design and Stress Analysis module.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button.

- Nominal Pipe Size(in)

- Wall Thickness(in) and

- Pipe Length(ft)

- Youngs Modulus of Elasticity(psi).

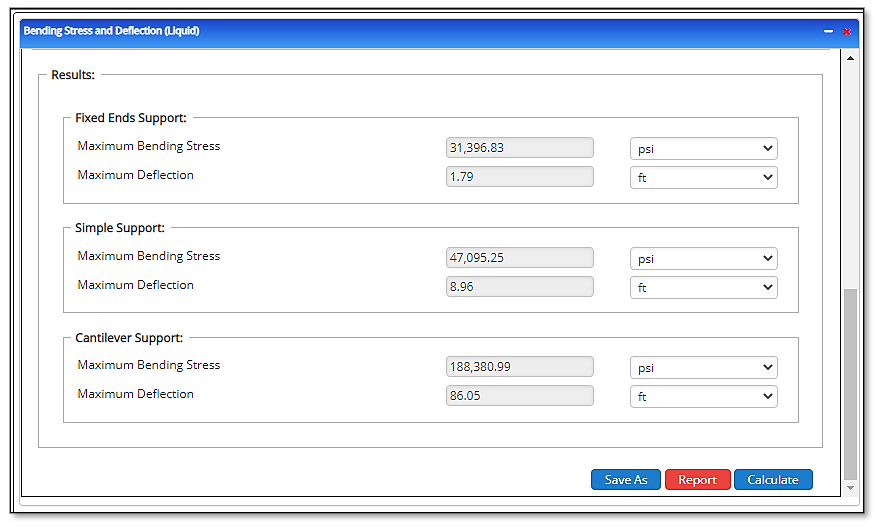

Outputs/Reports

- View the results.

- If an input parameter needs to be edited be sure to hit the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon.

- To delete a case, click the DELETE icon near the top of the widget.

- Produces calculations for these three support types.

- Fixed End Supports/ Simple Supports/Cantilever Supports

- Maximum Bending Stress(psi)

- Maximum Deflection(ft)