Wall Thickness - Steel Pipe

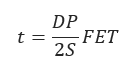

Wall thickness for steel pipe is calculated using an algebraic altered version of Barlow’s Equation. The wall thickness for steel pipe is determined in accordance with the following formula:

P = Design pressure(psi) gage.

S = yield strength(psi) determined in accordance with 192.107.

D = Nominal outside diameter of the pipe(in)

t = Nominal wall thickness of the pipe(in). If this is unknown, it is determined in accordance with 192.109. Additional wall thickness required for concurrent external loads in accordance with 192.103 may not be included in computing design pressure.

F = Design factor determined in accordance with 192.111.

E = Longitudinal joint factor determined in accordance with 192.113.

T = temperature derating factor determined in accordance with 192.115

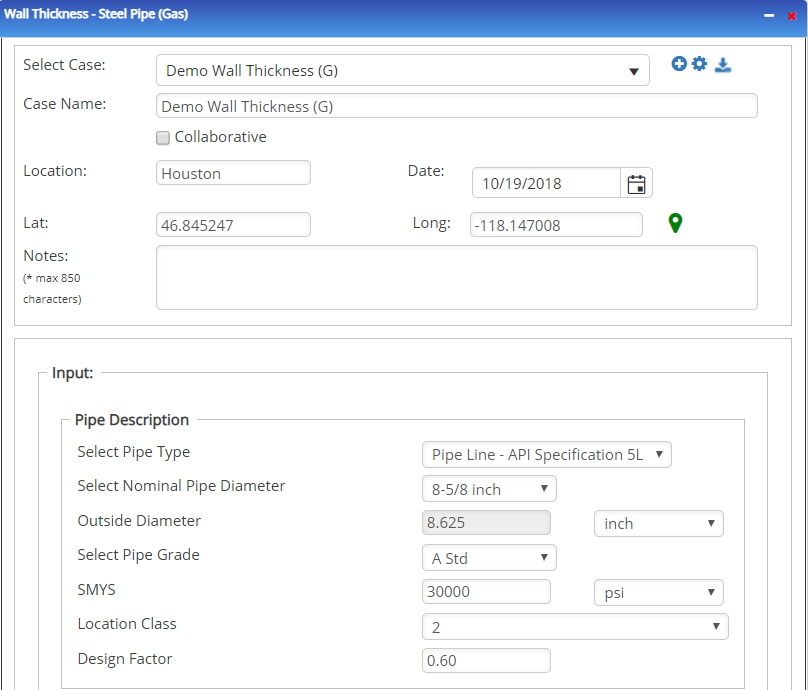

Input Parameters

- Select the Wall Thickness – Steel Pipe application from the Steel Pipe – Design and Stress Analysis module.

- To create a new case, click the “+” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button.

- Nominal Pipe Size(in):(0.625” – 48”)

- Wall Thickness(in):(0.068”- >2”)

- Pipe grade:(24000psi-80000psi) (if unknown use Grade A 24000)

- Design Factor: Reference 49 CFR 192.611

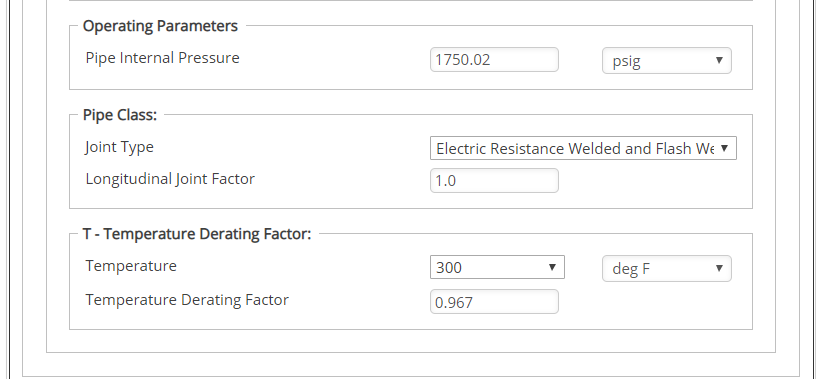

- E – Longitudinal Joint Factor

- T – Temperature Derating Factor(°F).

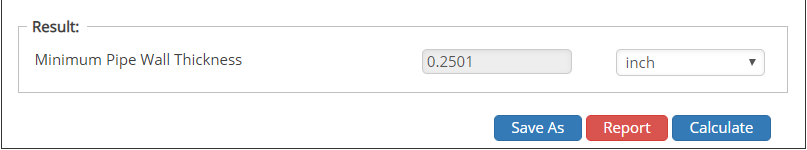

Outputs/Reports

- View the results.

- If an input parameter needs to be edited be sure to hit the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon.

- To delete a case, click the DELETE icon near the top of the widget.

- The single output this calculation provides a Minimum Pipe Wall Thickness(in).