Relief Valve: Reactive Force

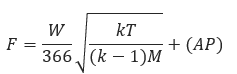

This calculation determines the force at the point of discharge of a pressure relieving device. API 520 indicates that the equation is for elbow and vertical exhaust pipe.

where

𝐹 − Reactive force at the point of discharge to the atmosphere(lbf)

𝑊 − Flow of gas(lbm/hr)

𝑀 − Molecular Weight of Gas

𝐴 = Area of outlet at the point of discharge(in2)

𝑇 − Temperature at outlet(°R)

𝑘 − Specific Heat Ratio (𝐶𝑃/𝐶𝑣) at the outlet conditions

P − Static pressure within the outlet at the pint of discharge(psig)

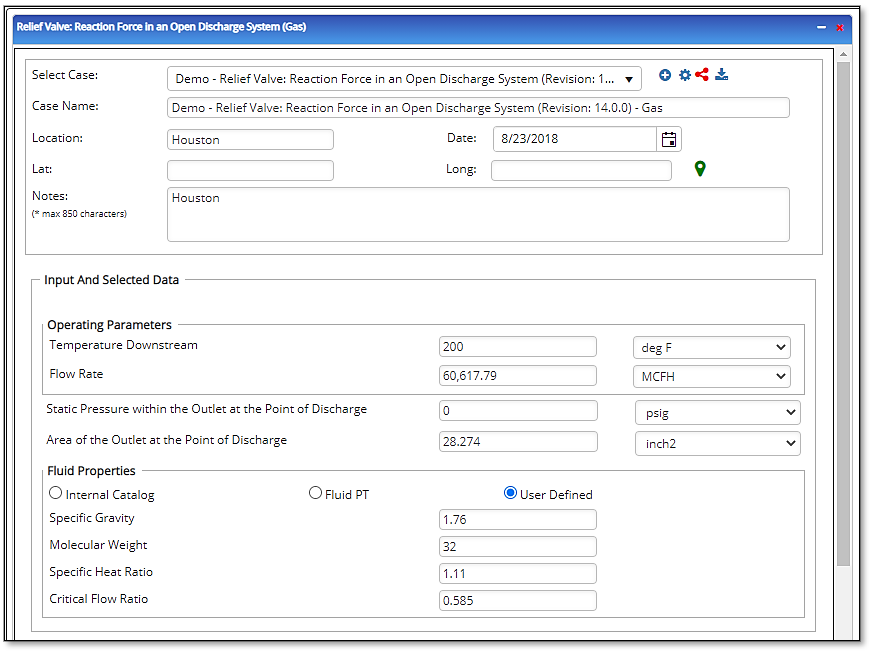

Input Parameters

- To create a new case, click the “Add Case” button

- Select the Relief Valve Reactive Force application from the Pipeline Facilities section.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button.

- Relief Valve Set Pressure (psig)

- Gas or Vapor Flowing Temperature (F)

- Back Pressure (psig)

- Required Flow through Valve (MSCFH)

- Kd – Effective Coefficient of Discharge

- Kb – Capacity Correction Factor

- Compressibility Factor of Gas or Vapor

- Molecular Weight of Gas or Vapor

- Specific Heat Ratio

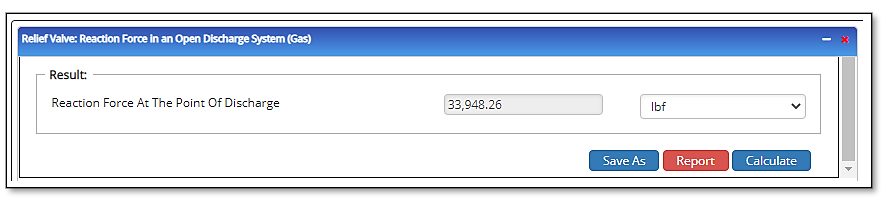

Outputs/Reports

- View the results.

- If an input parameter needs to be edited be sure to hit the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon.

- To delete a case, click the DELETE icon near the top of the widget.

- t – Required Wall Thickness of the Header

- (H – t) – Excess Thickness in the Header Wall

- tb – Required Wall Thickness of the Branch

- (B – tb) – Excess Thickness in the Branch Wall

- AR – Reinforcement Required

- A1 – Reinforcement Provided

- L – Height

- A2 – Effective Area in Branch/Outlet

- A2 – Corrected Effective Area

- A3 – REQUIRED AREA

- AP – PROVIDED AREA

- Reinforcement of Welded Branch Connection is: