Centrifugal Pump - Affinity Laws

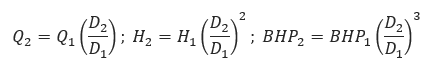

Impeller trimming (change) refers to the reduction of the impeller diameter, and thus a reduction of the circumferential speed at the impeller outlet of a centrifugal pump. The effect of this measure thus depends on the type of impeller. Single-vane and diagonal impellers can only be trimmed within narrow limits.

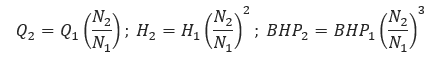

B. Speed Change Only:

In reciprocating pumps, the flow is not true steady-state flow, but is continually accelerating and decelerating due to the continual change in fluid velocity requires more energy, or acceleration head. Due to continual change in fluid velocity requires more energy, or acceleration head, so friction loss models may not be completely accurate when performing flow analysis.

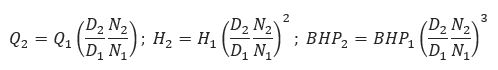

C. Diameter and Speed Change:

The relationship between variables involved in pump or fan performance (such as head, volumetric flow rate, shaft speed) and power. Specific speed is a term used to describe the geometry (shape) of a pump impeller. The selection of the proper pump can use this Specific Speed information to : Select the shape of the pump curve.

𝐷 − Impeller Diameter [in]

𝑄 − Capacity[gpm]

𝐻 − Head [ft]

𝐵𝐻𝑃 − Brake Horsepower

𝑁 − Speed [rpm]

Subscript1 for Original Conditions

Subscript2 for new Design Conditions

Input Parameters

- To create a new case, click the “Add Case” button

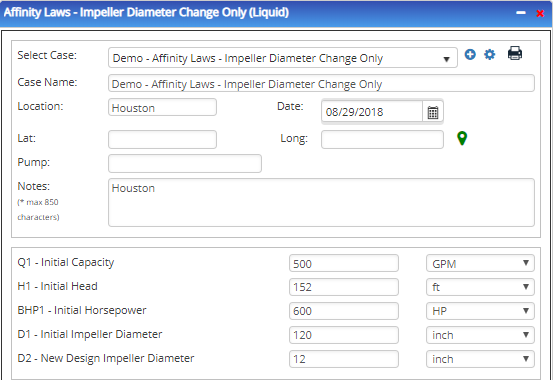

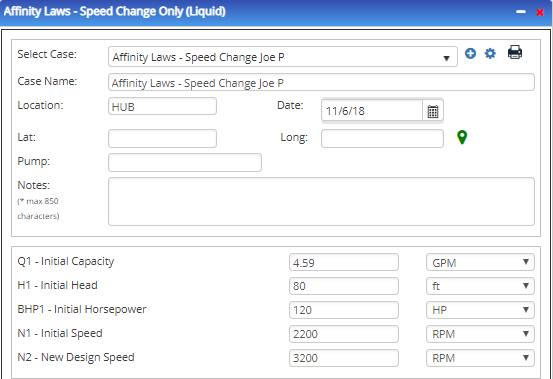

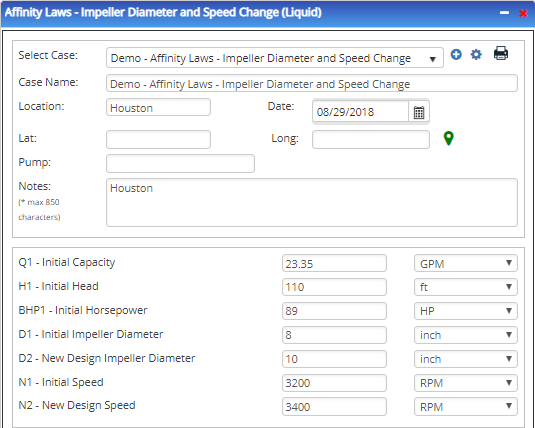

- Select the one of the three following applications in the Pipeline Pumps module: Affinity Laws – Impeller Diameter Change Only, Affinity Laws – Speed Change Only, Affinity Laws – Impeller Diameter and Speed Change.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button.

- Initial Capacity [gpm]

- Initial Head [ft]

- Initial Horsepower [HP]

- Initial Impeller Diameter [in]

- New Design Impeller Diameter [in]

- Initial Capacity [gpm]

- Initial Head [ft]

- Initial Horsepower [HP]

- Initial Speed [rpm]

- New Design Speed [rpm]

- Initial Capacity [gpm]

- Initial Head [ft]

- Initial Horsepower [HP]

- Initial Impeller Diameter [in]

- New Design Impeller Diameter [in]

- Initial Speed [rpm]

- New Design Speed [rpm]

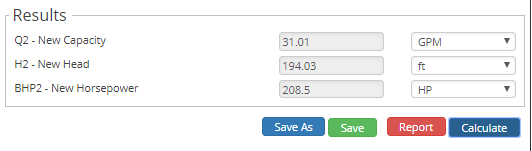

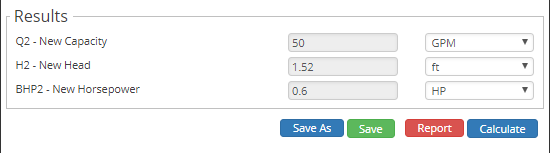

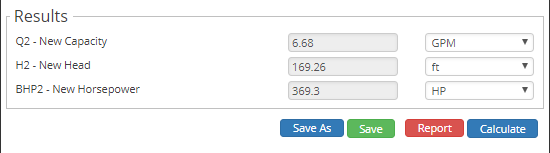

Outputs/Reports

- View the results.

- If an input parameter needs to be edited be sure to hit the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon.

- To delete a case, click the DELETE icon near the top of the widget.

- New Capacity [gpm]

- New Head [ft]

- New Horsepower [HP]

- New Capacity [gpm]

- New Head [ft]

- New Horsepower [HP]

- New Capacity [gpm]

- New Head [ft]

- New Horsepower [HP]