Pump Station Piping - Pipe Diameter and Average Flow Velocity

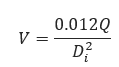

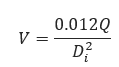

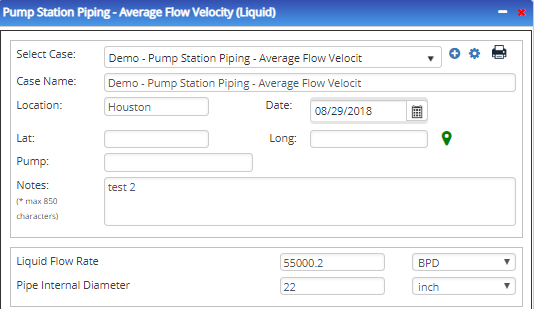

Calculating the average liquid flow using the internal diameter the average liquid velocity ft./sec can be calculated using flowrate and diameter. Significant changes in the liquid flow due to operational changes can be a limiting factor.

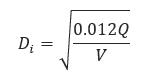

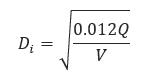

Pipe diameter is based on flow rate (barrels/day) and velocity (ft./sec) in accordance with API recommended practices. Change in inlet pressure can cause cavitation of the pump and create occurrences outside the limits this calculation.

𝑉 − Average Liquid Flow Velocity [ft/sec]

𝑄 − Liquid Flow Rate [bbl/day]

𝐷𝑖 − Internal Pipe Diameter [in]

Pipe diameter is based on flow rate (barrels/day) and velocity (ft./sec) in accordance with API recommended practices. Change in inlet pressure can cause cavitation of the pump and create occurrences outside the limits this calculation.

𝑉 − Average Liquid Flow Velocity [ft/sec]

𝑄 − Liquid Flow Rate [bbl/day]

𝐷𝑖 − Internal Pipe Diameter [in]

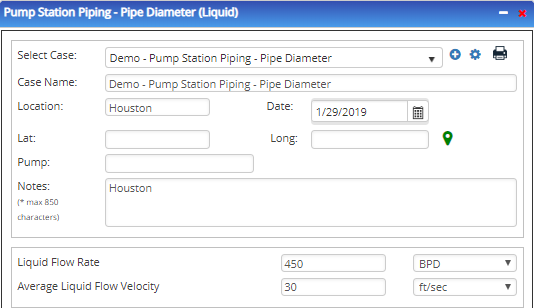

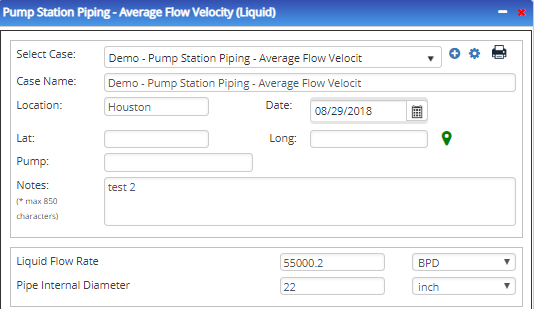

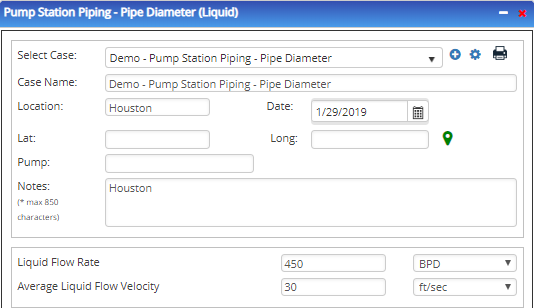

Input Parameters

- To create a new case, click the “Add Case” button

- Select the Pump Specific Speed application from the Pipeline Pumps module.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button

- Liquid Flow Rate [bbl/day]

- Average Liquid Flow Velocity

- Pipe Internal Diameter [in]

- Liquid Flow Rate [bbl/day]

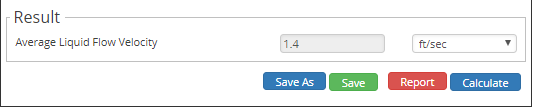

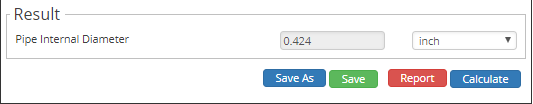

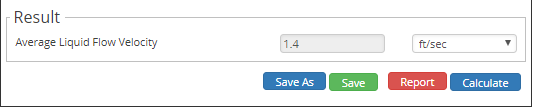

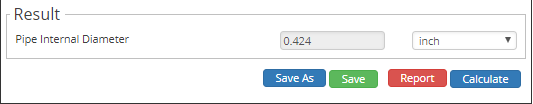

Outputs/Reports

- View the results.

- If an input parameter needs to be edited be sure to hit the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon.

- To delete a case, click the DELETE icon near the top of the widget.

- Pipe Internal Diameter

- Average Liquid Flow Velocity