Hydrostatic testing is a method to determine strength, expose defects, expose leak & validate integrity of the vessel. Typically, tests are conducted at 125% of MAOP.

These tests are limited to defects that are ready for failure such as cracks. The test pressure must be adjusted for the related allowable stress at the design temperature. This requires adjustments during the testing phase due to ambient temperature conditions.

Formulas

Volume of Water Required to Fill Test Section

![]()

𝑉 − Volume of Water to Fill Test Section[gal]

𝑑 − Inside Pipe Diameter[in]

𝐿 − Length of the Test Section[ft]

Volume of Water Required at Test Pressure

![]()

𝑉𝑡𝑝 − Volume of Water at Test Pressure and Test Temperature[gal]

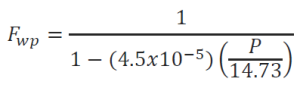

𝐹𝑤𝑝 − Correction Factor for the Compressibility of Water due to Inc of Pressure from 0 psi to Test Pressure

𝐹𝑝𝑝 − Correction Factor for Volume Change in Pipeline due to Increase of Pressure

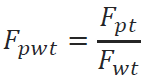

𝐹𝑝𝑤𝑡 − Correction Factor for the Change of Pipe and Water Volume due to Temperature Change from Base to Test Temperature

𝑃 − Test Pressure[psi]

![]()

𝐷 − Pipe Diameter[in]

𝑊𝑡 − Pipe Wall Thickness[in]

𝑃 − Test Pressure[psi]

𝑇1 − Test Temperature[°F]

![]()

𝐹𝑤𝑡 − Correction Factor for Thermal Change in Specific Water Volume from 60℉ to Test Water Temperature

Where:

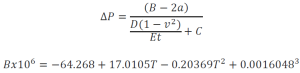

∆𝑃 − Pressure Change [psi/℃]

𝐵 − Coefficient of Expansion of Water

𝐷 − Pipe Outside Diameter [in]

𝐸 − Modulus of Elasticity for Steel 30×106[psi]

𝑣 − Poisson′s Ratio

𝐶 − Compressibility Factor for Water

𝑎 − Coefficient of Expansion for Steel 1.116×10−5/℃

𝑡 − Pipe Wall Thickness [in]

𝑇 − Temperature [℃]

Input Parameters

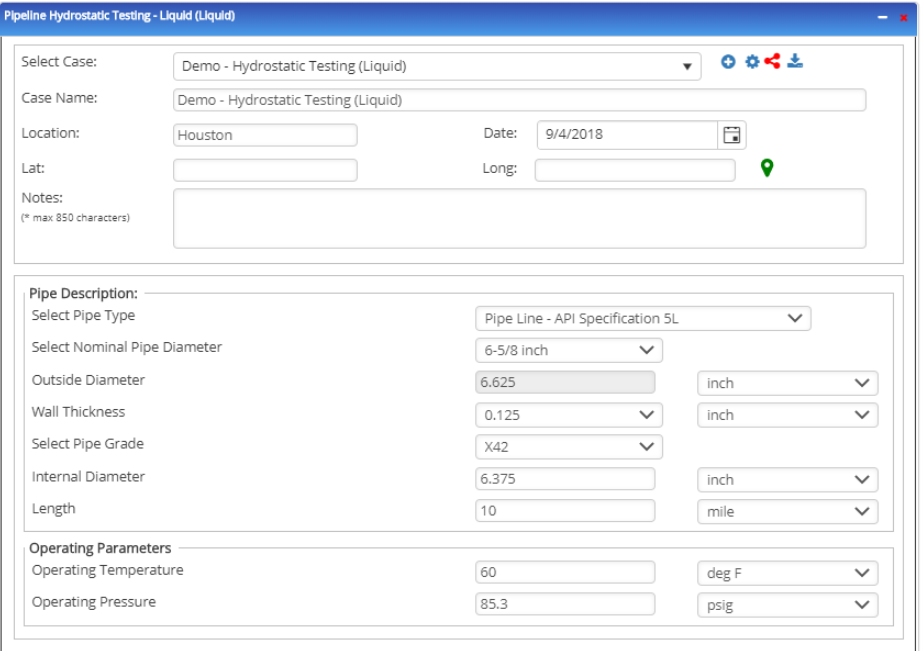

- To create a new case, click the “Add Case” button

- Select the Pipeline Hydrostatic Testing application from the Pipeline Testing module.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button.

- Nominal Pipe Size(in)

- Wall Thickness(in)

- Outside Diameter(in)

- Internal Diameter(in)

- Test Pressure(psi)

- Test Temperature (°F)

- Pipeline Length (miles)

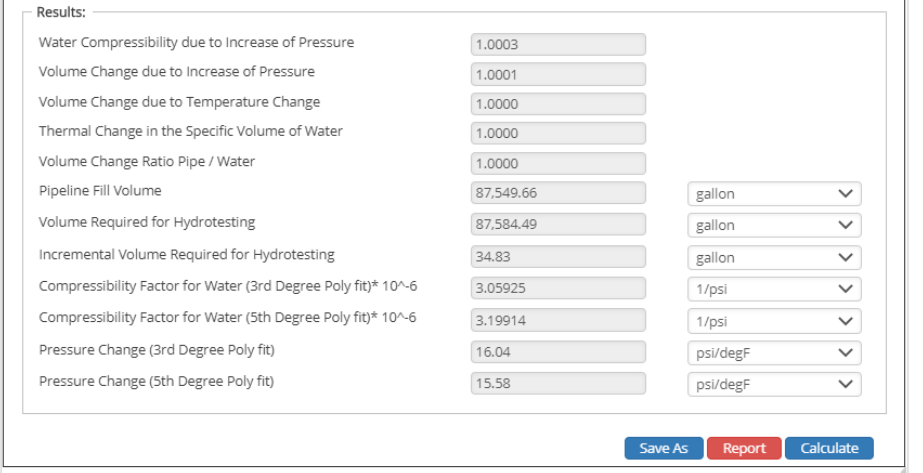

Outputs/Reports

- View the results.

- If an input parameter needs to be edited be sure to hit the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon.

- To delete a case, click the DELETE icon near the top of the widget.

- Water Compressibility due to Increase of Pressure

- Volume Change due to Increase of Pressure

- Volume Change due to Temperature Change

- Volume Change Ratio Pipe/Water, Pipeline Fill Volume(gal.)

- Volume Required for Hydrotesting (gal.)

- Incremental Volume Required for Hydrotesting (gal.)

- Compressibility Factor for Water (3rd Degree Poly fit) (in³/in³/psig) x10-6

- Compressibility Factor for Water (5th Degree Poly fit) (in³/in³/psig) x10-6

- Pressure Change (3rd Degree Poly fit) (psi/°F)

- Pressure Change (5th Degree Poly fit) (psi/°F).

Related Links