Gas Pipeline Pressure Testing - Maximum Pressure Drop

Maximum pressure drop is performed by balancing changes in the measured pressure in the test section against the theoretical pressure changes calculated from changes in the measured temperature of the test section.

Ambient temperature swings can cause challenges regarding pressure changes. Temperature gauges must far enough away from exposed piping to avoid erroneous readings.

Ambient temperature swings can cause challenges regarding pressure changes. Temperature gauges must far enough away from exposed piping to avoid erroneous readings.

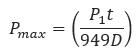

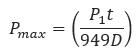

𝑃𝑚𝑎𝑥 − Maximum Pressure Drop[psi]

𝐷 − Internal Pipe Diameter[in]

𝑡 − Shut in Time[hr]

𝑃1 − Initial Test Pressure[psi]

Input Parameters

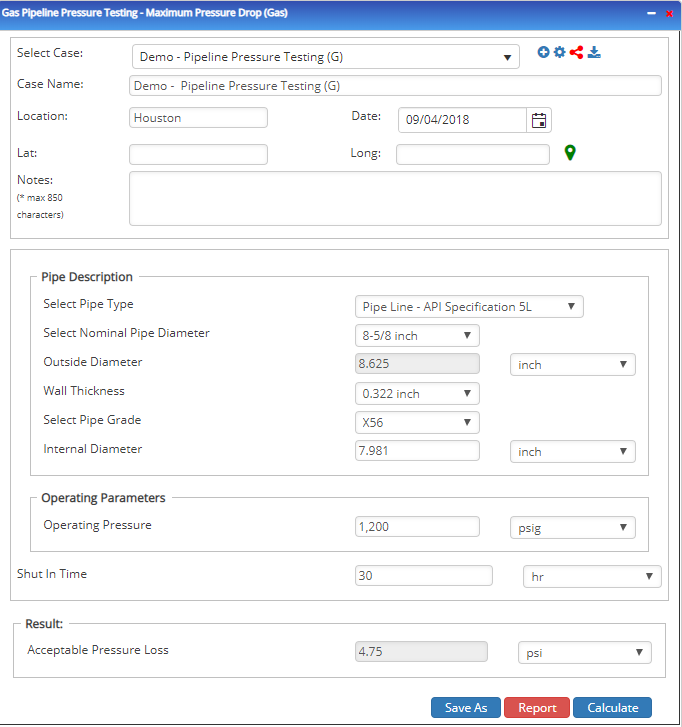

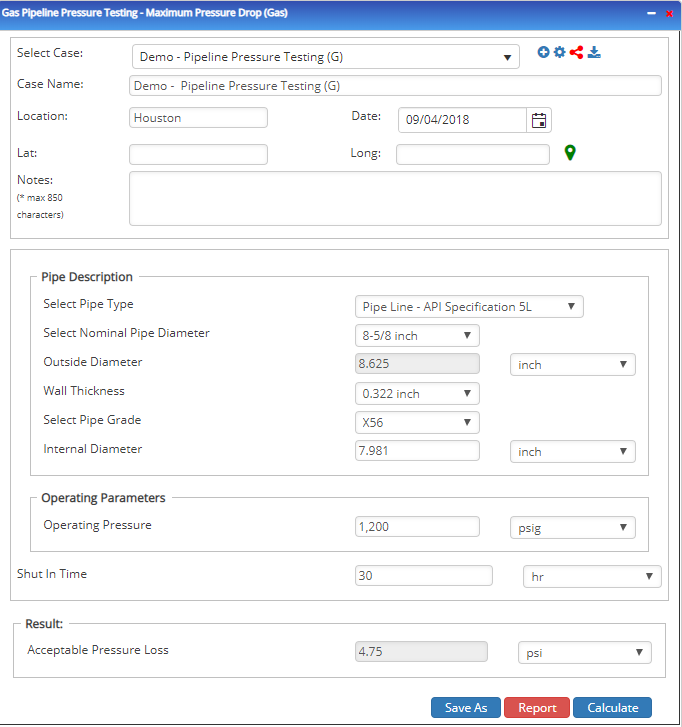

- To create a new case, click the “Add Case” button

- Select the Gas Pipeline Pressure Testing – Maximum Pressure Drop application from the Pipeline Testing module.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button.

- Initial Pressure(psi)

- Shut-in time(hr.)

- Internal pipe diameter(in)