HDD Operating Stress Analysis

A pipeline is subjected to three primary loading conditions during installation by HDD: tension, bending, and external pressure. A thorough design process requires examination of the stresses that result from each individual loading condition as well as an examination of the combined stresses that result from the interaction of these loads.

Hence, the stresses imposed on steel pipe during both the HDD installation process and subsequent operation should be carefully evaluated.

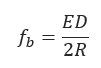

Bending Stress (fb)

Bending stress resulting from a rigid steel pipe

being forced to conform to the drilled radius of curvature

E =modulus of elasticity for steel (psi)

D = outside diameter of the pipe (inch)

R = Shortest Radius of Curvature (ft)

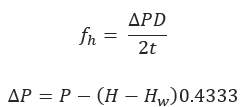

Hoop Stress (fh)

Steel pipe will fail by buckling or collapse when under the influence of hoop stress. It’s important to calculate the wall thickness required to prevent collapse of round steel pipe under the influence of hoop stress.

P = Operating Pressure (psig)

H = Depth of the Pipe at Horizontal Section (ft)

Hw = Groundwater Table below Datum (ft)

Thermal Stress (fe)

Thermal stress resulting from changes in pipe temperature from the point in time at which the pipe is restrained by the surrounding soil to typical operating conditions.

𝑓𝑒 = 𝐸𝛼 (𝑇1 − 𝑇2)

𝐸 − Young′s Modulus of Elasticity 𝐸 = 29 x 106

𝛼 − Coefficient of Thermal Expansion for steel α = 6.5 x 106 [in/in℉]

T1 = Installation Temperature (°F)

T2 = Operating Temperature (°F)

Total Longitudinal Compressive Stress

𝑓𝑙 = -𝑓𝑏 + 𝑓ℎ * 𝜗+ 𝑓𝑒

fl = Total Longitudinal Compressive Stress

𝜗 = Poisson′s Ratio = 0.3

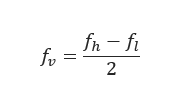

Maximum Shear Stress (fv)

Maximum Allowable Shear Stress (fva)

𝑓𝑣𝑎 = 0.45𝑆𝑀𝑌𝑆

SMYS – Specified minimum Yield Stress for Steel Pipe (psi)

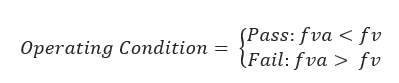

Operating Conditions

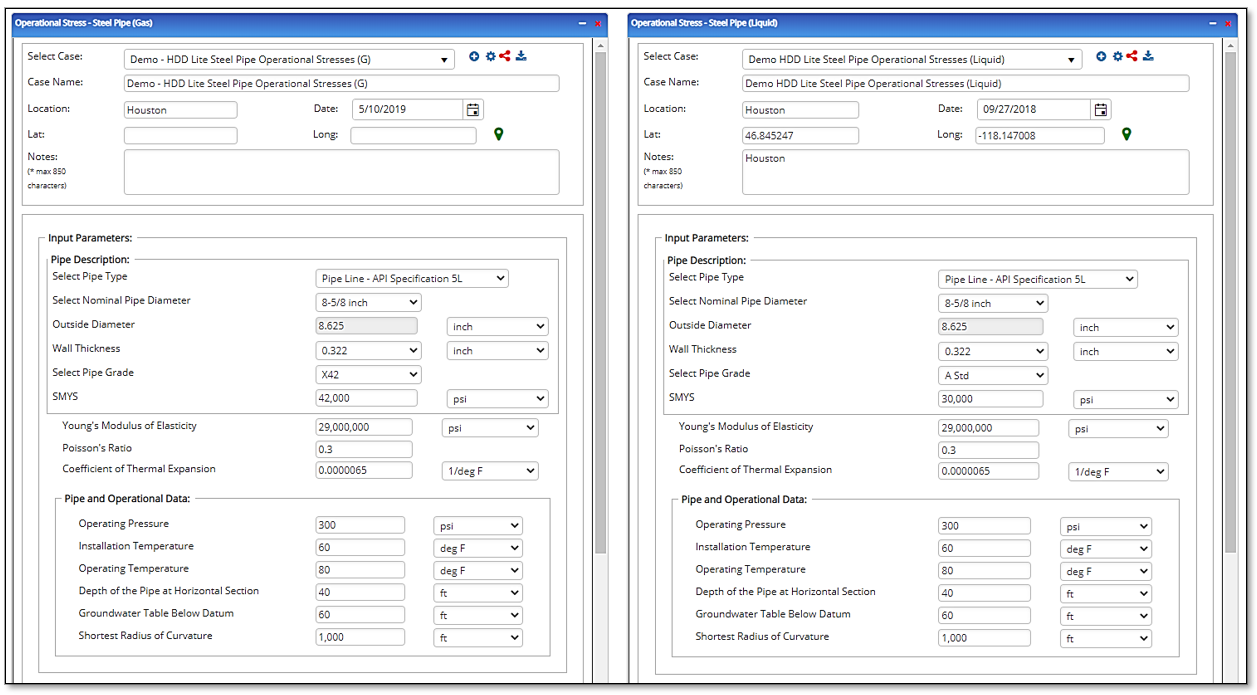

Input Parameters

- To create a new case, click the “Add Case” button

- Select the Operational Stresses – Steel Pipe application in the HDD Steel Pipe module

- Enter Case Name, Location, Date, and any necessary notes

- Fill out all required fields

- Make sure the values you are inputting are in the correct units

- Click the CALCULATE button

Poisson’s Ratio

Poisson’s Ratio- Young’s Modulus of Elasticity [psi]

- Thermal Expansion Coefficient [in./in.°F]

- Operating Pressure [psig]

- Pipe Outside Diameter [in.]

- Pipe Wall Thickness [in.]

- Specified Minimum Yield Strength [psi]

- Installation Temperature [°F]

- Operating Temperature [°F]

- Depth of the Pipe at Horizontal Section [ft]

- Groundwater Table below Datum [ft]

- Shortest Radius of Curvature [ft]

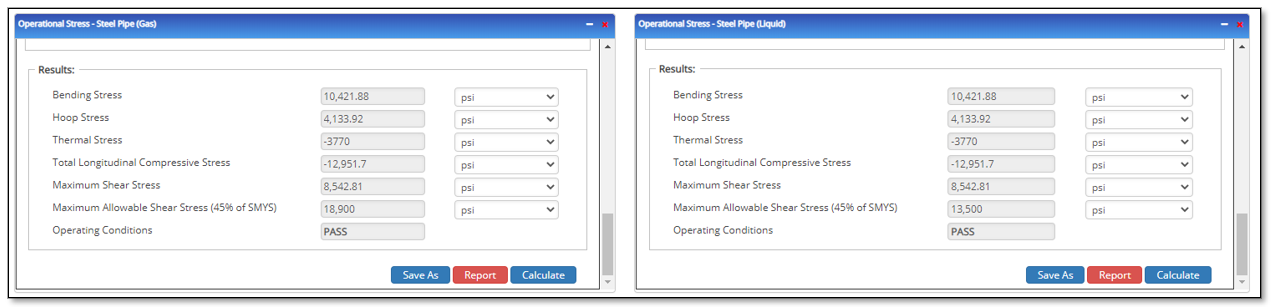

Outputs/Reports

View the results

View the results- If an input parameter needs to be edited be sure to hit the CALCULATE button after the change

- To SAVE, fill out all required case details then click the SAVE button

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE

- To generate a REPORT, click the REPORT button

- The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon

- To delete a case, click the DELETE icon near the top of the widget

- Bending Stress [psi]

- Hoop Stress [psi]

- Thermal Stress [psi]

- Total Longitudinal Compressive Stress [psi]

- Maximum Shear Stress [psi]

- Maximum Allowable Shear Stress (45% of SMYS)

- Operating Conditions