Distributed Static Surcharge Load: Not Directly Beneath a Surcharge Load

Similar approach to directly below, the active earth force is calculated due to simultaneous effect of both the soil weight and the surcharge of strip load over the pipe to determine earth pressures.

Dead/Earth LoadA. Prism Load

𝑃𝑝 = 𝑤𝐻

𝑃𝑝 = Vertical Soil Pressure[lb/ft2]

𝑤 = Unit Weight of Soil[lb/ft2]

𝐻 = Height of Soil Above Pipe Crown[ft]

B. Marston Load (ASCE Manual No.60)

𝑃𝑚 = 𝐶𝑑𝑤𝐵𝑑𝑃𝑚 = Vertical Soil Pressure[lb/ft2]

𝑤 = Unit Weight of Soil[lb/ft2]

𝐵𝑑 = Trench Width at Pipe Crown[ft]

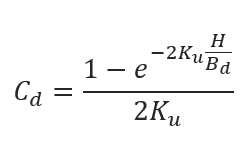

𝐶𝑑 = Load/Trench Coefficient

𝑒 = Base of Natural Logarithm[2.71828]

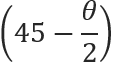

𝐾 = Rankine Earth Pressure Coefficient

𝐾 = 𝑡𝑎𝑛2

𝜃 = Angle of Internal Soil Friction,[°]

𝑢 = Coefficient of Friction between Backfill and Trench Sides

C. Combined Prism and Marston Load

For flexible pipe, a more conservative method is to use a soil pressure load in between prism and Marston load:

𝑃𝑐 = 0.6𝑃𝑚 + 0.4𝑃𝑝 𝑃𝑐 = Combined Load or Modified Arching Soil Pressure[lb/ft2]

Distributed Static Surcharge Load Not Over PE Pipe

This method is using Boussinesq equation for pressure acting on pipe crown.

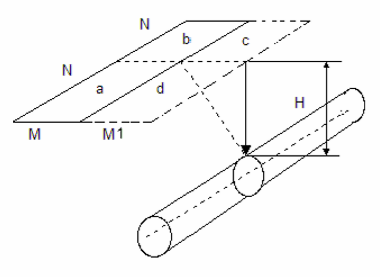

𝑃𝑑𝑝 = 𝑃𝑎+𝑑 + 𝑃𝑏+𝑐 – 𝑃𝑐 − 𝑃𝑑

𝑃𝑖 = 𝐼𝐶𝑤𝑖

𝑃𝑑𝑝 = Subcharge Distributed Load Pressure at Point on Pipe Crown[lb/ft2]

𝑃𝑎+𝑑 = Combined Sub Area a and d Subcharge Load[lb/ft2]

𝑃𝑏+𝑐 = Combined Sub Area b and d Subcharge Load[lb/ft2]

𝑃𝑐 = Sub Area c Subcharge Load[lb/ft2]

𝑃𝑑 = Sub Area d Subcharge Load[lb/ft2]

𝑃𝑖 = Sub Area Subcharge Load at ith Area[a + d, b + c, c or d]

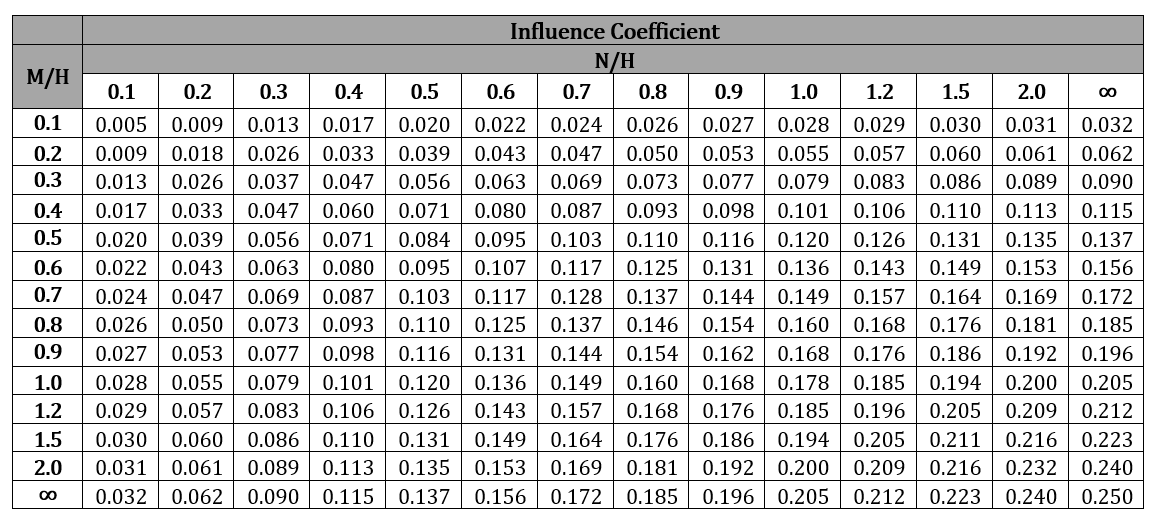

𝐼𝐶 = Influence Coefficient

𝑤𝑖 = Distributed Surcharge Pressure Acting over ith Area[a + d, b + c, c or d]

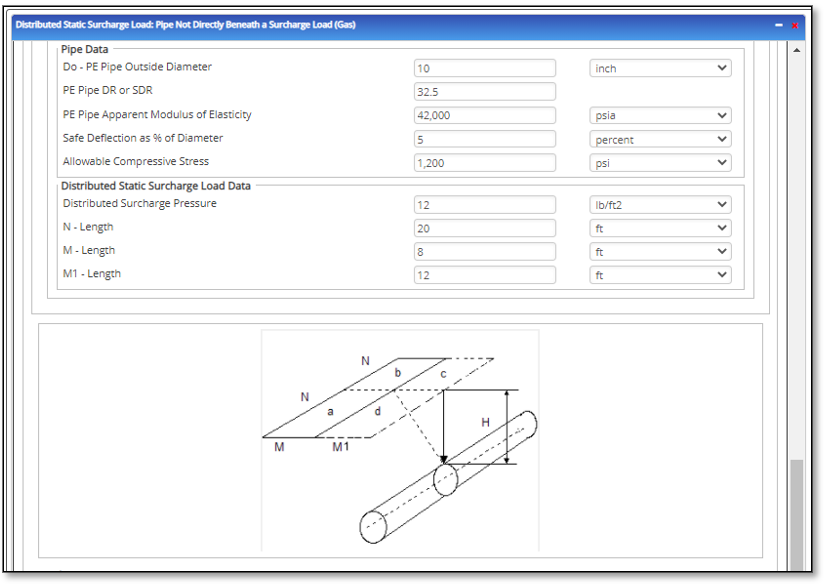

Influence coefficient is selected from the table below:𝐻 = Vertical Distance from Surface to Crown of Pipe,[ft]

𝑀 = Horizontal Distance Normal to Pipe Centerline, from the Center of Load Area,[ft]

𝑁 = Horizontal Distance Parallel to Pipe Centerline, from the Center of Load Area,[ft]

Influence coefficient is selected from the table below:

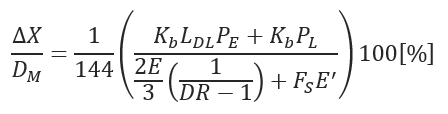

Pipe Deflection is calculated using Spangler’s Modified Iowa Formula:

Pipe Deflection is calculated using Spangler’s Modified Iowa Formula:

∆𝑋 = Horizontal Deflection,in.

𝐷𝑀 = Mean Diameter,in.

𝐾𝑏 = Bedding Factor

𝐿𝐷𝐿 = Deflection Lag Factor

𝑃𝐸 = Vertical Soil Pressure due to Earth Load[lb/ft2]

𝑃𝐿 = Vertical Soil Pressure due to Live Load[lb/ft2]

𝐸 = Apparent Modulus of Elasticity of Pipe Material[psi]

𝐸′ = Modulus of Soil Reaction[psi]

𝐹𝑆 = Soil Support Factor

𝐷𝑅 = Standard Dimension Ratio DR

𝑡 = Minimum Pipe Wall Thickness [in]

- Modulus of Soil Reaction (E’) – Average Values for Iowa Formula (see table in section 2.0)

- Modulus of Soil Reaction (E’) – Values of E’ for Pipe Embedment (see table in section 2.0)

- Values of E’n Native Soil Modules of Soil Reaction (see table in section 2.0)

- Soil Support Factor (see table in section 2.0)

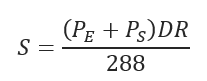

𝑆 = Pipe Wall Compressive Strength [psi]

𝑃𝐸 = Vertical Soil Pressure due to Earth Load,[lb/ft2]

𝑃𝑆 = Vertical Soil Pressure due to Surcharge Load[lb/ft2]

𝐷𝑅 = Standard Dimension Ratio DR

𝐷𝑜 = Pipe Outside Diameter [in]

𝑡 = Minimum Pipe Wall Thickness [in]

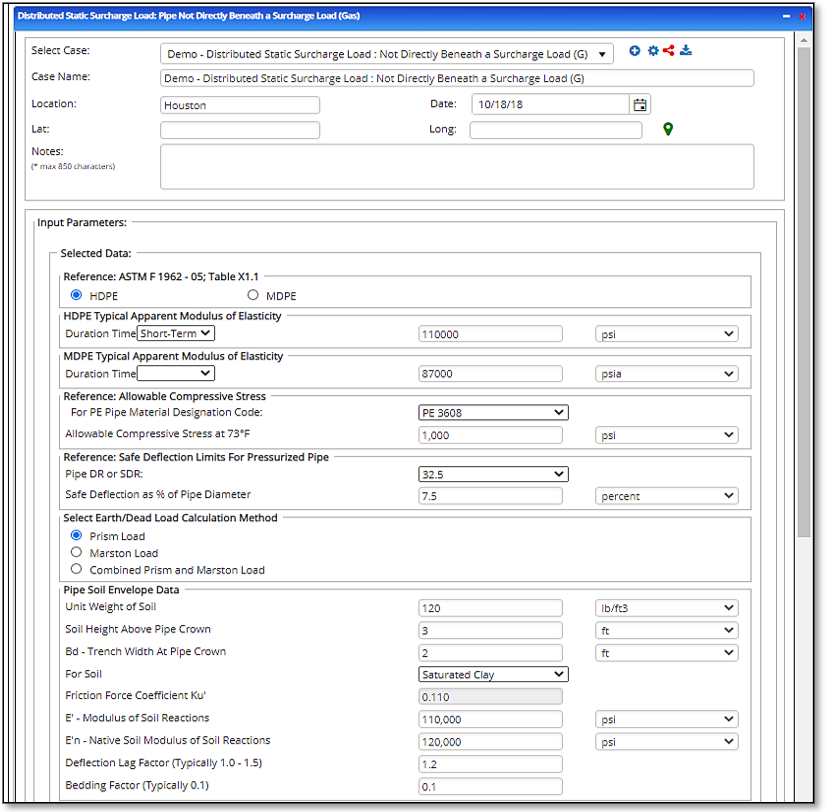

Input Parameters

- To create a new case, click the “Add Case” button

- Select the Distributed Static Surcharge Load: PE Pipe Not Directly Beneath a Surcharge Load application from the Polyethylene Pipe – Design & Stress Analysis module list.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required fields.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button.

-

- Reference: ASTM F 1962

- HDPE Typical Apparent Modulus of Elasticity

- Duration Time

- Reference: Allowable Compressive Strength

- For PE Pipe Material Designation Code:

- Reference: Safe Deflection Limits for Pressurized Pipe

- Pipe DR/SDR

- Select Earth/Dead Load Calculation Method

- Pipe Soil Envelope Data

- Unit Weight of Soil

- Soil Height above Pipe Crown

- Bd – Trench Width at Pipe Crown

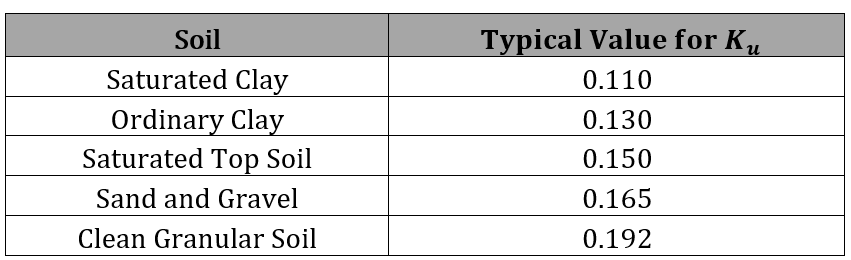

- For Soil:

- Friction Force Coefficient Ku

- E’ – Modulus of Soil Reaction

- E’n- Native Soil Modulus of Soil Reaction

- Deflection Lag Factor (Typically 1.0 – 1.5)

- Bedding Factor (Typically 0.1)

- Pipe Data

- Do – PE Pipe Outside Diameter

- PE Pipe DR or SDR

- PE Pipe Apparent Modulus of Elasticity

- Safe Deflection as % of Diameter

- Allowable Compressive Stress

- Static Load

- Distributed Surcharge Pressure

- N – Length

- M – Length

- M1 – Length

- Reference: ASTM F 1962

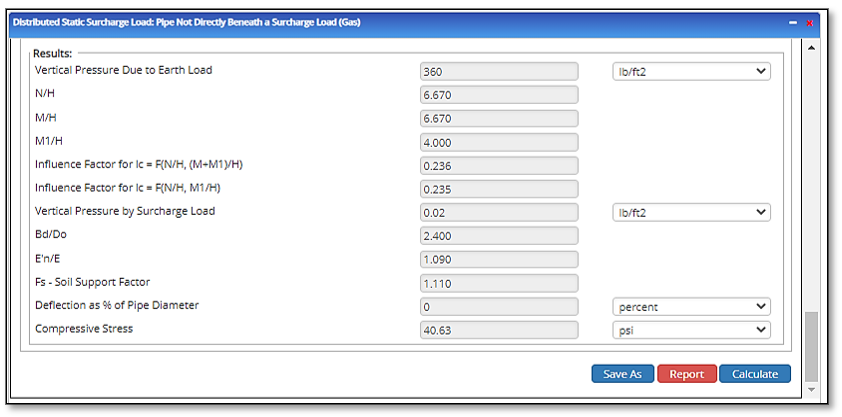

Outputs/Reports

- View the results.

- If an input parameter needs to be edited be sure to hit the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel/PowerPoint icon.

- To delete a case, click the DELETE icon near the top of the widget.

- Vertical Pressure due to Earth Load

- N/H

- M/H

- M1/H

- Influence Factor for Ic = F (N/H, M/H)

- Influence Factor for Ic = F (N/H, M1/H)

- Vertical Pressure by Surcharge Load

- Bd/Do

- E’n/E

- Fs – Soil Support Factor

- Deflection as % of Pipe Diameter

- Compressive Stress