PRCI RSTRENG Data Input

Definitions

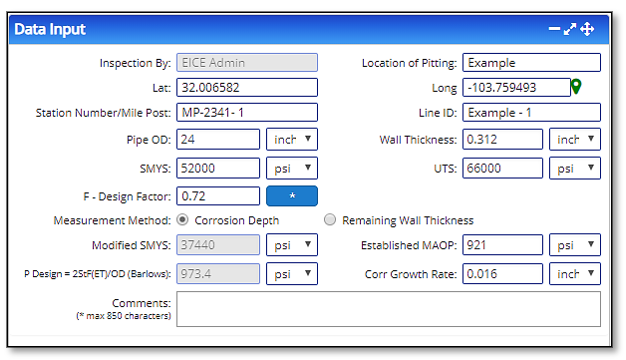

Following pipe configuration, the user records data necessary for RSTRENG calculations in this widget.

Inspection By

The name on the user account is displayed in this field which is a non-editable field.

Location of Pitting

Captures the location of pitting data as entered by the user.

Geographical Location

This location (Latitude/Longitude) can either be of the pipe or the defect itself. The icon beside this input field is used to select a point on the Map.

Station Number/Mile Post

User input data used for identification.

Line ID

User input data used for identification.

Pipe OD

User input data for the outside diameter of the pipe for RSTRENG assessment.

Wall Thickness

User input data for wall thickness of the pipe used for assessment.

SMYS

User input data for Specified Minimum Yield Strength (SMYS) of the pipe used for RSTRENG calculations.

UTS

User-specified data for Ultimate Tensile Stress (UTS) used in additional Maximum safe pressure Calculations.

Factor – Design Factor

User-specified design factor of the pipe to perform RSTRENG calculations.

Measurement Method

The user specifies whether the data provided will be Corrosion depth or the remaining wall thickness which is supported by the RSTRENG application.

Corrosion Depth

User selects corrosion depth (pit depth) data from ILI (in-Line Inspection) as the basis of the calculation.

Remaining Wall Thickness

User selects remaining wall thickness data from ILI as the basis of the RSTRENG calculation.

Modified SMYS

A calculated value that is given by SMYS * F – Design Factor.

P Design (Barlow)

P – Design/Design Pressure/Barlow’s Pressure is calculated using (2*SMYS* thickness*F) / OD.

Established MAOP

User-defined Maximum Allowable Operating Pressure (MAOP).

Corrosion Growth Rate

User-defined parameter used for remaining life and re-assessment interval calculations.

Comments

Section for the user to make notes with a maximum limit set to 850 characteristics