Introduction

This calculation applies to 180,000 lb. dual tandem gear assembly with 26 in spacing between tires and 66 in center to center with 12″ rigid pavement. This calculation may be limited for heavier or larger aircraft such as military type.

Dead/Earth Load

A. Prism Load

P_p=wH

P_p=wH

𝑃𝑝 = Vertical Soil Pressure, [lb/ft2]

𝑤 = Unit Weight of Soil, [lb/,ft2]

𝐻 = Height of Soil Above Pipe Crown, [ft]

B. Marston Load (ASCE Manual No.60)

P_m=C_dwB_d

P_m=C_dwB_d

𝑃𝑚 = Vertical Soil Pressure, [lb/,ft2]

𝑤 = Unit Weight of Soil, [lb/,ft2]

𝐵𝑑 = Trench Width at Pipe Crown, [ft]

𝐶𝑑 = Load/Trench Coefficient

C_d = \frac{1 – e^{-2K_u\frac{H}{B_d}}}{2K_u}

C_d = \frac{1 - e^{-2K_u\frac{H}{B_d}}}{2K_u}𝑒 = Base of Natural Logarithm, [2.71828]

𝐾 = Rankine Earth Pressure Coefficient

𝐾 = 𝑡𝑎𝑛2 (45-θ/2)

𝜃 = Angle of Internal Soil Friction, [°]

𝑢 = Coefficient of Friction between Backfill and Trench Sides

C. Combined Prism and Marston Load

For flexible pipe, a more conservative method is to use a soil pressure load in between prism and Marston load:

𝑃𝑐 = 0.6𝑃𝑚 + 0.4𝑃𝑝

𝑃𝑐 = Combined Load or Modified Arching Soil Pressure, [lb/ft2]

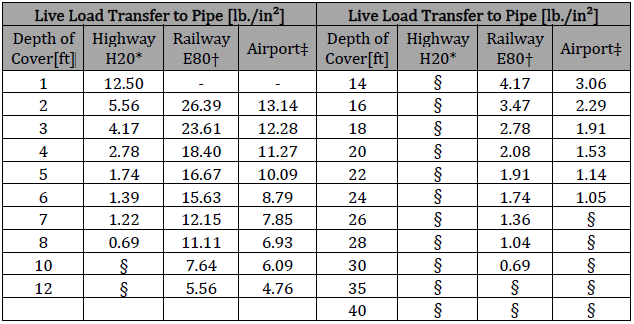

Live Load: Aircraft Load on Buried PE Pipe

* Simulates a 20-ton truck traffic load, with impact factor

† Simulates an 80,000 lb./ft railway load, with impact factor

‡ Applies to 180,000 lb. dual-tandem gear assembly, with 26 in. spacing between tires and 66 in. center to center spacing between fore and aft tire under a rigid 12 in. pavement, with impact factor

§ Negligible influence of live load on buried pipe

Pipe Deflection is calculated using Spangler’s Modified Iowa Formula:

\frac{\Delta X}{D_M} = \frac{1}{144} \left( \frac{K_bL_{DL}P_E + K_bP_L}{\frac{2E}{3}(\frac{1}{DR-1} )+F_SE’} \right) \times 100\%

\frac{\Delta X}{D_M} = \frac{1}{144} \left( \frac{K_bL_{DL}P_E + K_bP_L}{\frac{2E}{3}(\frac{1}{DR-1} )+F_SE'} \right) \times 100\%

∆𝑋 = Horizontal Deflection,in.

𝐷𝑀 = Mean Diameter,in.

𝐾𝑏 = Bedding Factor

𝐿𝐷𝐿 = Deflection Lag Factor

𝑃𝐸 = Vertical Soil Pressure due to Earth Load[lb/ft2]

𝑃𝐿 = Vertical Soil Pressure due to Live Load[lb/ft2]

𝐸 = Apparent Modulus of Elasticity of Pipe Material[psi]

𝐸′ = Modulus of Soil Reaction[psi]

𝐹𝑆 = Soil Support Factor

𝐷𝑅 = Standard Dimension Ratio DR = Do /t

𝐷𝑜 = Pipe Outside Diameter [in]

𝑡 = Minimum Pipe Wall Thickness [in]

Parameter Reference Table:

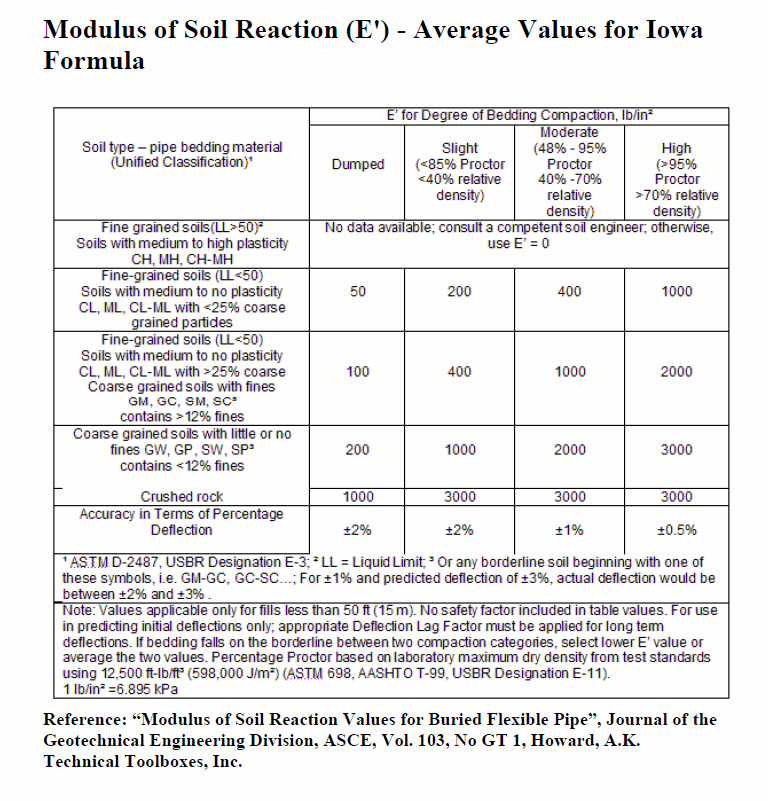

Modulus of Soil Reaction (E’) – Average Values for Iowa Formula

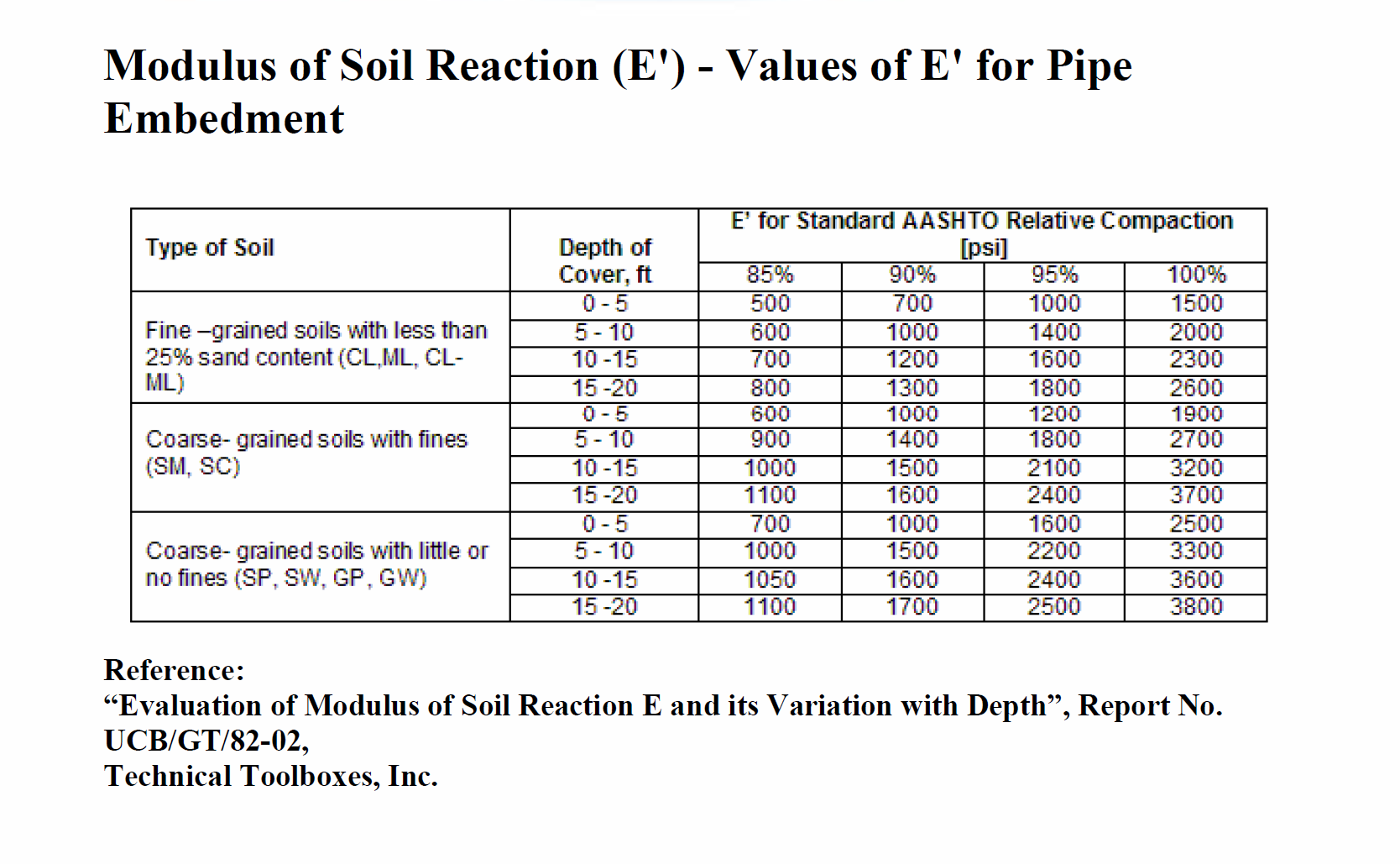

Modulus of Soil Reaction (E’) – Values of E’ for Pipe Embedment

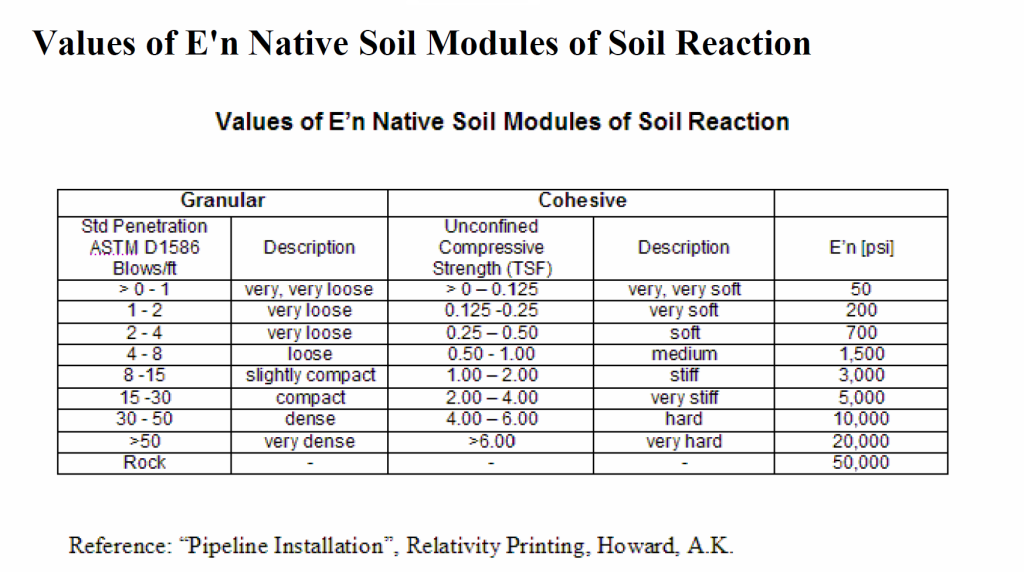

Values of E’n Native Soil Modules of Soil Reaction

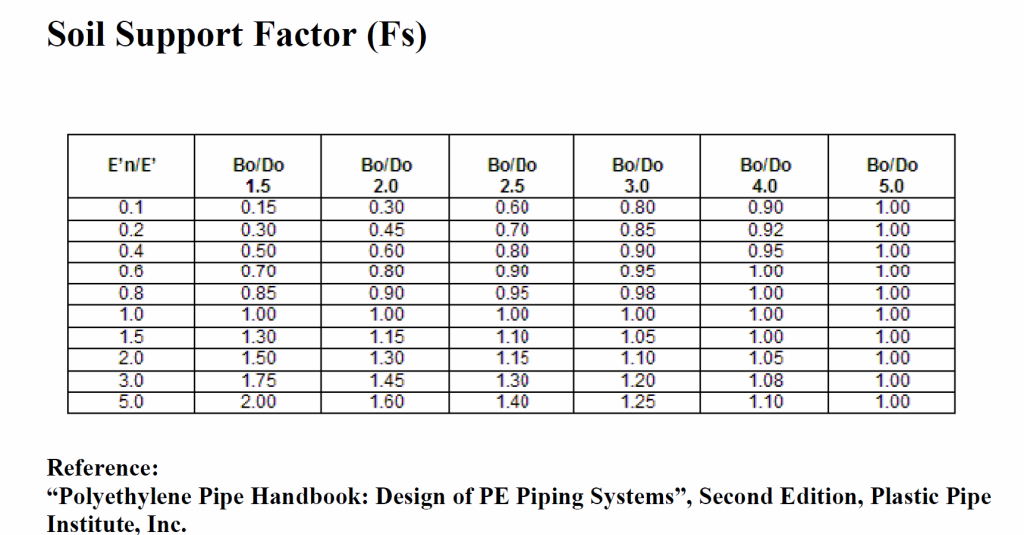

Soil Support Factor (Fs)

Pipe Wall Compressive Stress (PE Pipe Crushing):

S=\frac{(P_E+P_S)DR}{288}

S=\frac{(P_E+P_S)DR}{288}𝑆 = Pipe Wall Compressive Strength [psi]

𝑃𝐸 = Vertical Soil Pressure due to Earth Load, [lb/ft2]

𝑃𝑆 = Vertical Soil Pressure due to Surcharge Load, [lb/ft2]

𝐷𝑅 = Standard Dimension Ratio DR = Do /t

𝐷𝑜 = Pipe Outside Diameter [in]

𝑡 = Minimum Pipe Wall Thickness [in]

Case Guide

Part 1: Create Case

- Select the Live Load: Aircraft Load on Buried PE Pipe application from the Polyethylene Pipe Module

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

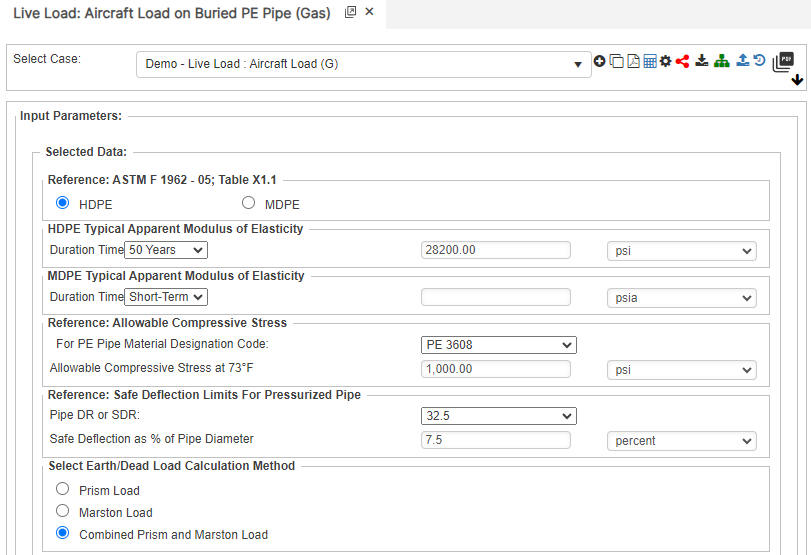

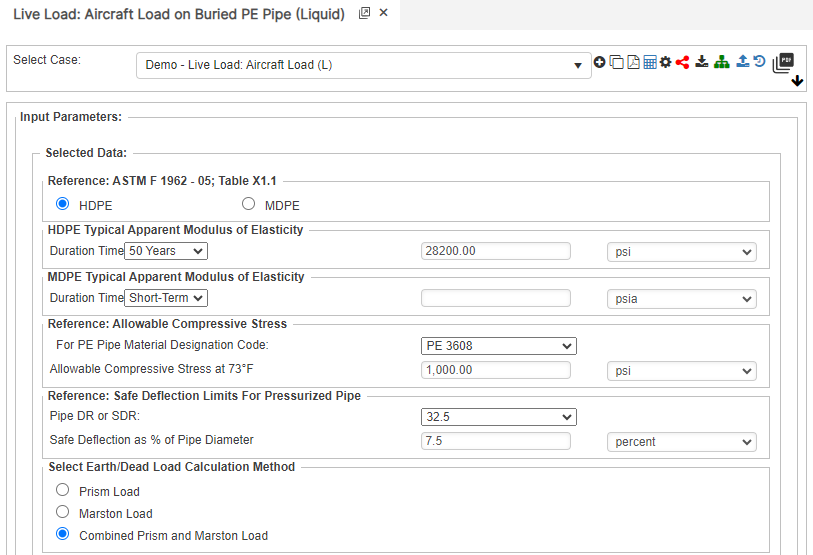

Input Parameters

- Reference: ASTM F 1962

- HDPE Typical Apparent Modulus of Elasticity

- Duration Time

- Reference: Allowable Compressive Strength

- For PE Pipe Material Designation Code:

- Reference: Safe Deflection Limits for Pressurized Pipe

- Pipe DR/SDR

- Select Earth/Dead Load Calculation Method

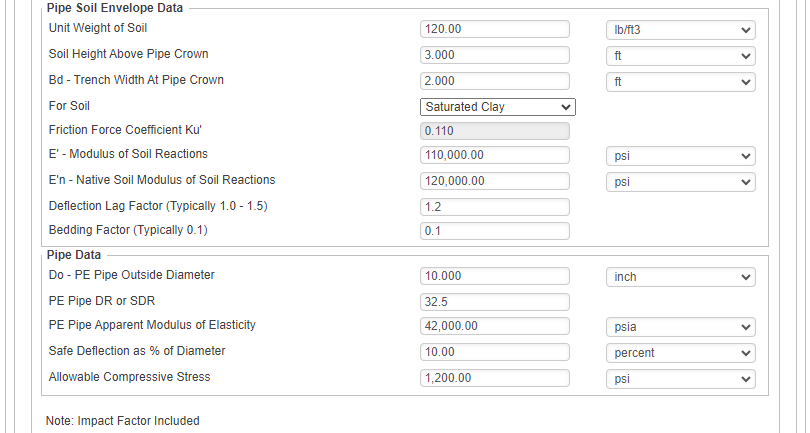

- Pipe Soil Envelope Data

- Unit Weight of Soil

- Soil Height above Pipe Crown

- Bd – Trench Width at Pipe Crown

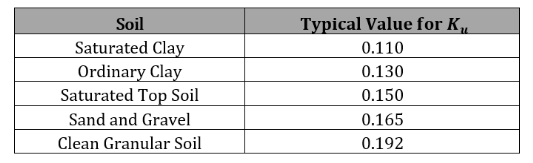

- For Soil:

- Friction Force Coefficient Ku

- E’ – Modulus of Soil Reaction

- E’n- Native Soil Modulus of Soil Reaction

- Deflection Lag Factor (Typically 1.0 – 1.5)

- Bedding Factor (Typically 0.1)

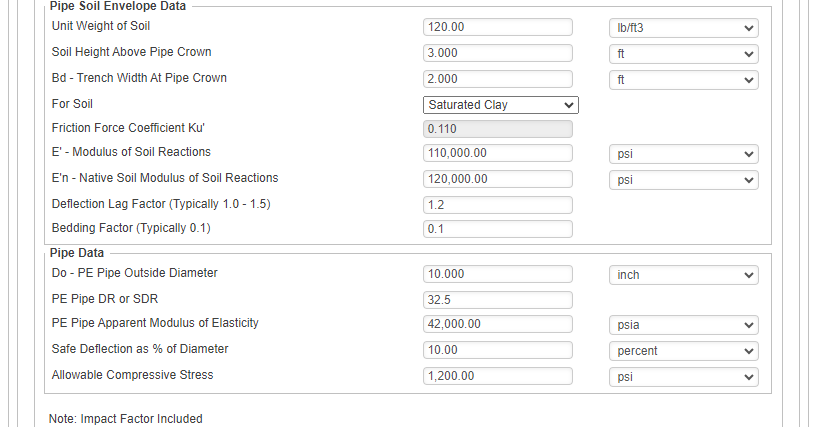

- Pipe Data

- Do – PE Pipe Outside Diameter

- PE Pipe DR or SDR

- PE Pipe Apparent Modulus of Elasticity

- Safe Deflection as % of Diameter

- Allowable Compressive Stress

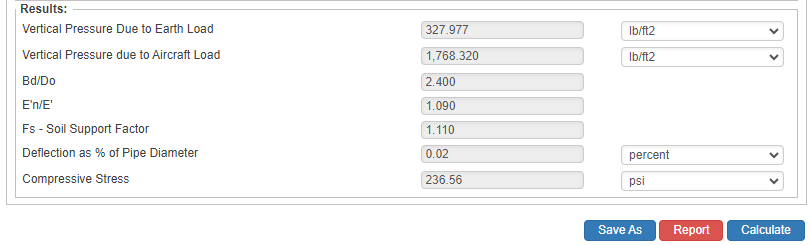

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

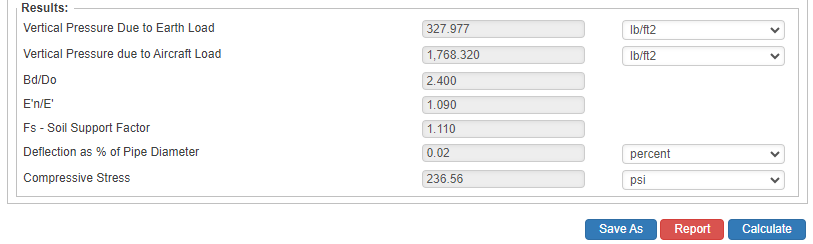

Results

- Vertical Pressure due to Earth Load (lb/ft2)

- Vertical Pressure by Aircraft Load (lb/ft2)

- Bd/Do

- E’n/E

- Fs – Soil Support Factor

- Deflection as % of Pipe Diameter

- Compressive Stress (psi)

References

- “Modulus of Soil Reaction Values for Buried Flexible Pipe”, Journal of the Geotechnical Engineering Division, ASCE, Vol. 103, No GT 1, Howard, A.K. Technical Toolboxes, Inc.

- “Evaluation of Modulus of Soil Reaction E and its Variation with Depth”, Report No. UCB/GT/82-02,

- “Soil Engineering”, Third Edition, Spangler, M.G. and Handy, R.L., Intext Educational Press

- “Structural Mechanics of Buried Pipes”, Watkins, R.K, and Loren, R, A,

- “Polyethylene Pipe Handbook: Design of PE Piping Systems”, Second Edition, Plastic Pipe Institute, Inc.

- API 15LE – Specification for Polyethylene Line Pipe

FAQ

-

Properties of Polyethylene Pipes?

This property data is a summary of similar materials in the MatWeb database for the category “High Density Polyethylene (HDPE), Injection Molded”.

Each property range of values reported is minimum and maximum values of appropriate MatWeb entries. The comments report the average value, and number of data points used to calculate the average.

The values are not necessarily typical of any specific grade, especially less common values and those that can be most affected by additives or processing methods. Check Out