Buoyancy analysis for concrete coating and weight spacing are two common methods used in pipeline construction to control buoyancy in water environments.

Buoyancy analysis and Concrete Coating Requirements –

This application is for the design of new pipe where the concrete coating is applied around each joint of pipe except for the cut back areas around the girth welds. These areas could be left open with corrosion coating or fitted with for concrete or other coating for mechanical protection to make up height difference if is used for an offshore using lay barge. It can be done either in plant for offshore or on the job site onshore manually by using forms around the pipe and having concrete trucks fill the area between the forms and corrosion coating.

Buoyancy Analysis and Concrete Weight Spacing –

This application is usually done onshore where there are wet land areas such a swamp, wetlands, etc. These calculations are set up for the separate weights, spaced at specific distances to keep the pipeline from floating to the surface. Example is a bolt on concrete weight as shown in the photo below. There are companies that have these concrete weights designed for each pipe size with quick installation. Note the wood lathes to protection the corrosion coating.

Calculations

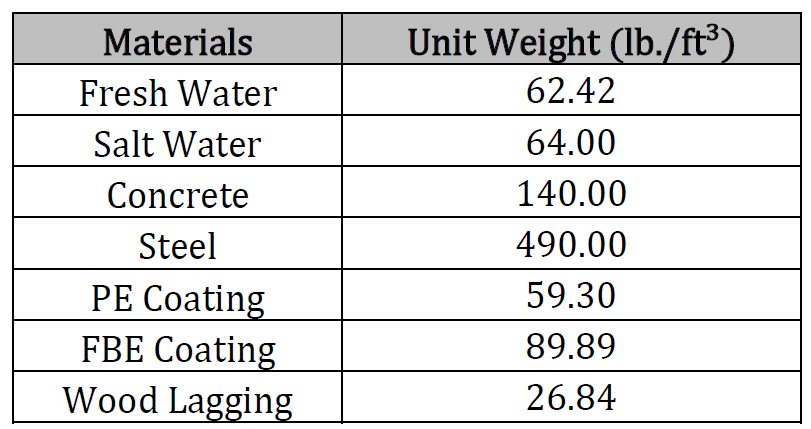

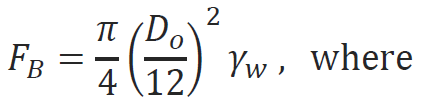

Buoyancy Force

𝐹𝐵 − Buoyancy Force (lbf)

𝐷𝑜 − Pipe outside diameter including coating (in)

𝛾𝑤 − Unit weight of fluid/water (lb/ft3)

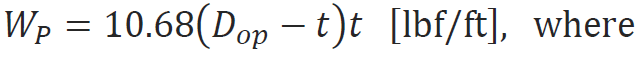

Weight of Steel Pipe in the Air

𝑊𝑃 − Weight of bare pipe in air (lbf)

𝐷𝑜𝑝 − Pipe outside diameter (in)

𝑡 − Pipe wall thickness (in)

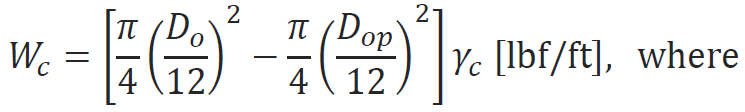

Weight of Pipe Coating in the Air

𝑊𝑐 − Weight of coating in air (lbf)

𝛾𝑐 − Unit weight of coating (lb/ft3)

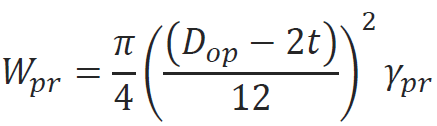

Weight of Product in the Pipe

𝑊𝑝𝑟 − Weight of product in pipe (lbf)

𝛾𝑝𝑟 − Unit weight of product in pipe (lb/ft3)

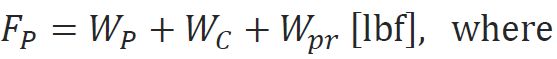

Downward Force of the Pipe

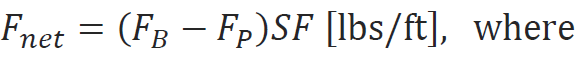

Net Controlling Force

𝐹𝑛𝑒𝑡 − Net controlling force (lbf)

𝑆𝐹 = Safety Factor

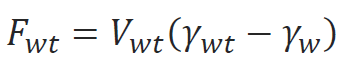

Downward Force of the Concrete Weight

𝑉𝑤𝑡 − Weight of concrete (ft3)

𝛾𝑤𝑡 − Unit weight of concrete (lb/ft3)

𝛾𝑤 − Unit weight of fluid/water (lb/ft3)

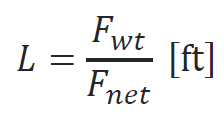

Concrete Weight Spacing