Introduction

As early as 1934, The American Petroleum Institute (API) recognized the need to develop a recommended practice for installation of pipelines crossing under railroads. This first effort was API Code 26.

In 1952, as the result of several years of effort and modifications to API Code 26, the API released the first edition of Recommended Practice 1102. This first edition, titled Steel Pipelines Crossing Railroads and Highways, included design criteria for pipelines crossing both railroads and highways.

In 1968, the API released an updated version of API 1102 which then contained the most recent data available on both uncased carrier pipe and casing design. This release considered the effects of dead (earth) and live (cyclic) loading and internal pressure.

M.G. Spangler’s work was used extensively to support the criteria in this 1968 edition of the API 1102. Spangler’s Iowa Formula was used to calculate the stress in un-cased carrier pipe and to determine wall thickness for casing pipe.

As time passed, it became apparent that the API 1102 (1968) criteria was conservative and in 1985 the Gas Research Institute (GRI) began a project at Cornell University to update the design methodology.

Casing Problems

The pipeline industry begins to experience casing problems such as carrier pipe leaks/failures under road crossings.

- Atmospheric corrosion due to condensation (particularly at elevated temperatures and cold soils)

- Metal to metal shorts

- Electrolytic coupling or contact

- Shielding by casing wall particularly if by coatings or spacers

- Difficulty of inspection to find and fix problems

- Lower Grade Pipe was used such as Grades A & B

- Fabrication was done by welders’ helpers to practice welding skills

- No consistent specifications

- Unknown condition of the metal loss on cased pipe

Assessments

Can the casing pipe protect the carrier pipe from external loadings?

- If casing pipe specification is available? Yes with heavy wall casing pipe and No with the above caveats

- Many assumptions would have to be made to use Wheel or Track Load calculations

- If the cased pipe ovalized to a degree of not returning to original condition, a permanent metallic short would occur

- If case pipe specification is not available? Yes and No with unknown carrier pipe, a 24,000 SMYS default with above caveats

- Many assumptions would have to be made to use Wheel or Track Load calculations

- If the cased pipe ovalized to a degree of not returning to original condition a permanent metallic short would occur

It should be noted that Wheel and Track Load, API 1102 Road/Rail programs cannot determine the percentage of ovalization due to the many unknowns as discussed. The carrier pipe could be assessed; however, electrical tests as per AMPP Standard Practice “Steel-Cased Pipeline Practices” should be used to test for metallic shorted conditions if heavy equipment crosses these structures.

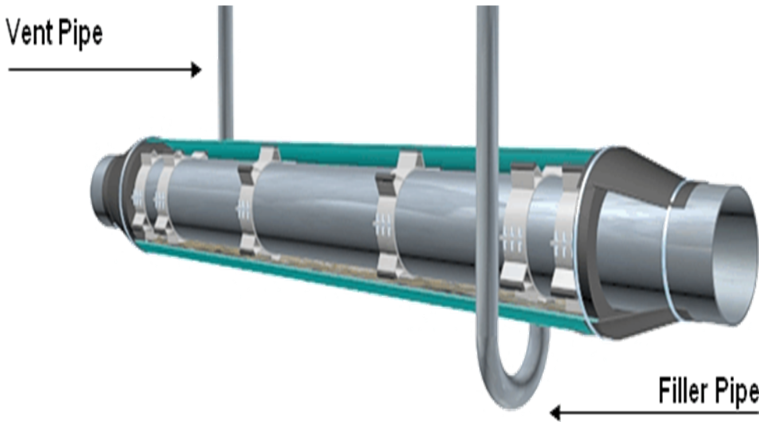

Below is a diagram of Casing and Carrier Pipe with two vents at a road crossing. One vent pipe is used to fill the annulus of the casing/carrier pipe with a high dielectric fill material such as a wax to prevent water or moisture build up.

Casing/Carrier Pipe