Introduction

The Pittsburgh equation is used in low pressure pipelines as in distribution systems. It was implemented to determine a pressure drop in a pipe segment under various flowrates in a like fashion to the other equations in this manual.

This equation has similar accuracy issues as with other distribution system equations. It can be used within the following ranges: D<6″.P_1>1.5psi\~\ Q=C_Q\sqrt{\bigg[ \frac{(P_1(P_1-P_2)P_2)}{0.0806L}D^{4.5} \bigg]}

D<6".P_1>1.5psi\\~\\ Q=C_Q\sqrt{\bigg[ \frac{(P_1(P_1-P_2)P_2)}{0.0806L}D^{4.5} \bigg]}𝐷 − Internal Pipe Diameter (in)

𝑄 − Flow Rate (ft/day)

𝐶𝑄 – 1000

𝐿 − Length of Pipeline(mi)

𝑃1 − Upstream Pressure (psig)

𝑃2 − Downstream Pressure (psig)

Case Guide

Part 1: Create Case

- Select the Pittsburgh application in the Hydraulics module.

- To create a new case, click the “Add Case” button.

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results

Input Parameters

- Temperature base(°F)

- Pressure base(psia)

- Gas Flowing Temperature(°F)

- Gas Specific Gravity

- Compressibility Factor

- Pipeline Efficiency Factor

- Upstream Pressure(psig)

- Downstream Pressure(psig)

- Flow Rate(MSCFH)

- Internal Pipe Diameter(in)

- Length of Pipeline(mi)

- Upstream Elevation(ft)

- Downstream Elevation(ft)

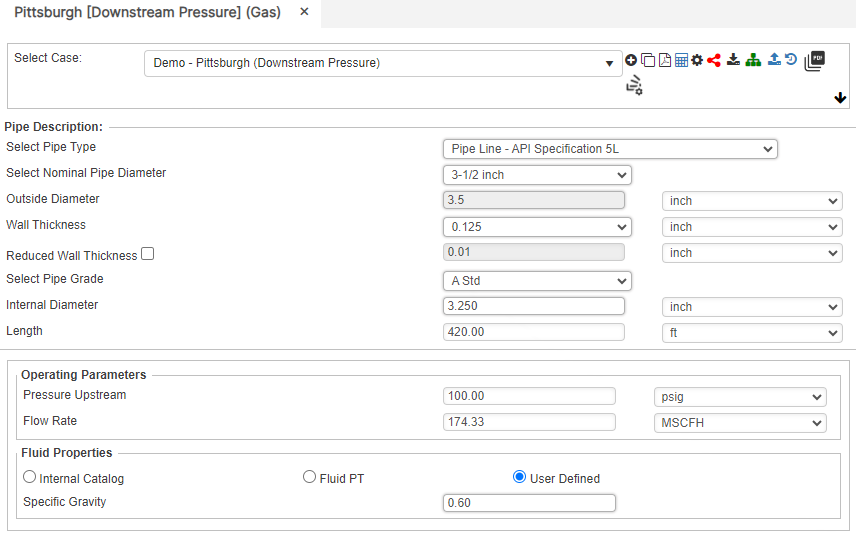

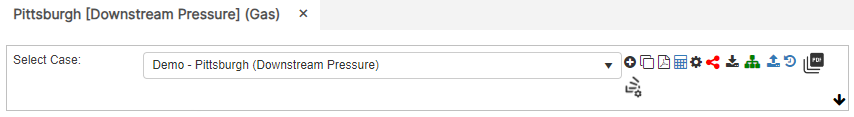

Downstream Pressure

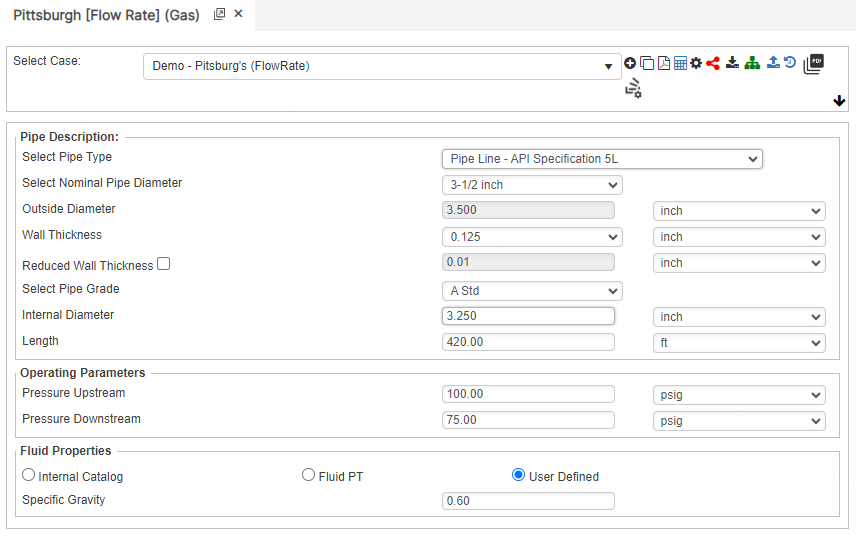

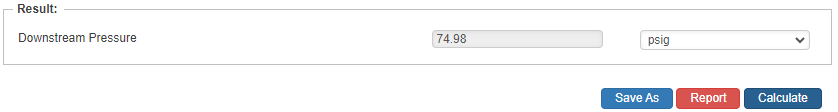

Flow Rate

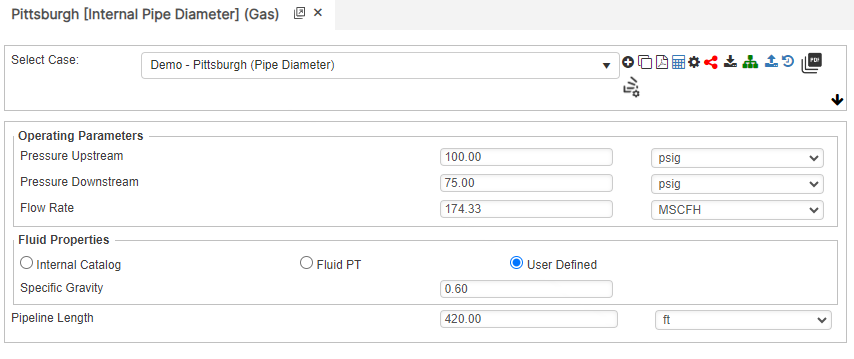

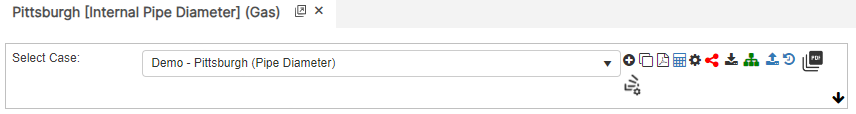

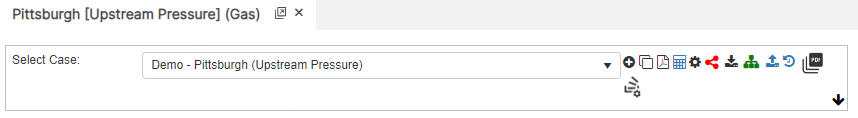

Internal Pipe Diameter

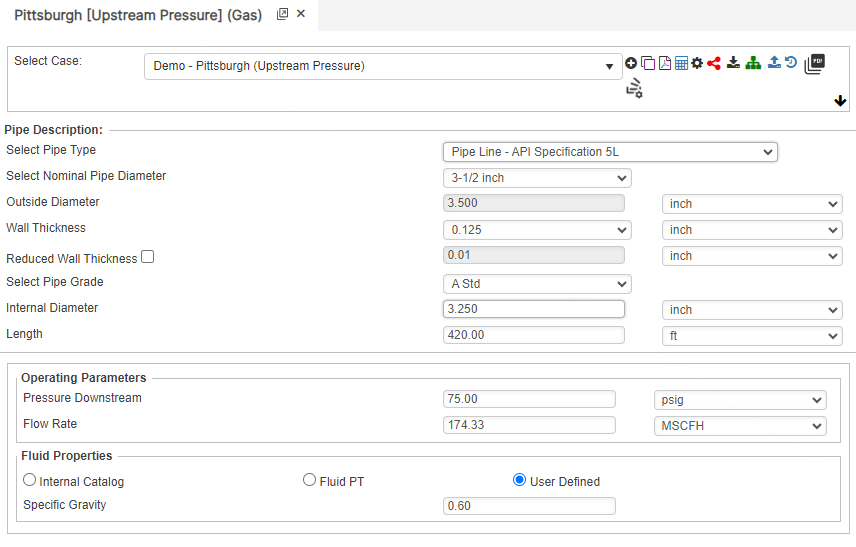

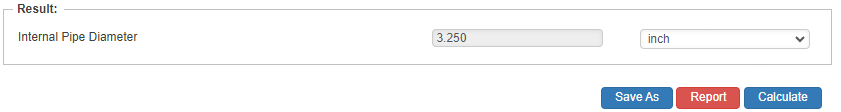

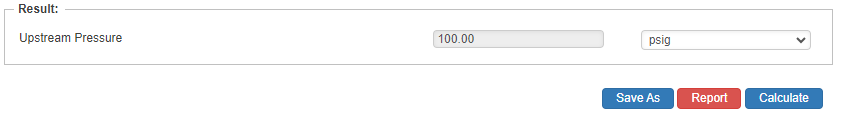

Upstream Pressure

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

Results

- Downstream Pressure(psig)

- Flow Rate(ft/sec.)

- Internal Pipe Diameter(in)

- Upstream Pressure(psig)

Downstream Pressure

Flow Rate

Internal Pipe Diameter

Upstream Pressure

References

- McAllister, E. W., “Pipeline Rules of Thumb” Gulf Professional Publishing, Seventh Edition

- Menon, Shahi E., “Gas Pipeline Hydraulics”, Systek Technologies, Inc.

- Carroll, Landon and Hudkins, Weston R., “Advanced Pipeline Design”

- American Gas Association (AGA), “Reference: Eq-17-18, Section 17, GPSA”, Engineering Data Book, Eleventh Edition

FAQ

-

Gas Purging Calculations?

Purging is a process of removing gas from the pipeline. Controlled purging of gases from pipelines by direct displacement with other gases that have been safely practiced for many years with the recognition that some flammable mixture is present. Purging of gases from pipelines by direct displacement with another gas also has been similarly practiced. It works both ways; however, there will always be an atmosphere of type of a mixture. This is due to the densities of the gases. Check Out

-

What is Erosional Velocity?

Pipe erosion begins when velocity exceeds the value of C/SQRT(ρ) in ft/s, where ρ = gas density (in lb./ft3) and C = empirical constant (in lb./s/ft2) (starting erosional velocity). We used C=100 as API RP 14E (1984). However, this value can be changed based on the internal conditions of the pipeline. Check Out

-

What is Sonic Velocity?

The maximum possible velocity of a compressible fluid in a pipe is called sonic velocity. Oilfield liquids are semi-compressible, due to dissolved gases. Check Out