Introduction

Acceleration head is the energy required to change the velocity of the liquid in the system from an at rest, or zero condition, to some non-zero value. Low pressure situations occurring on the inlet side of the pump can have an adverse effect on fluid movement. If the inlet pressure for the pump drops too low, it can cause performance issues, and damage the pump if internal cavitation occurs. : H_a=\frac{Lv_anC}{K_g}

H_a=\frac{Lv_anC}{K_g}Where:

𝐻𝑎 − Acceleration Head (gpm)

𝐿 − Length of Suction Line (ft)

𝑣𝑎 − Average Liquid Velocity in Suction Line (ft/sec)

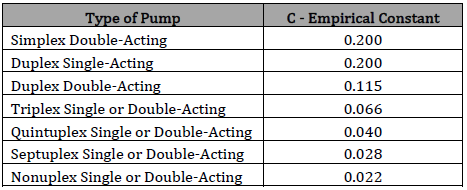

𝐶 − Empirical Constant for Type of Pump

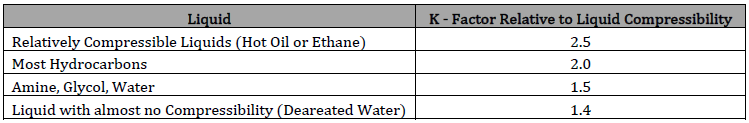

𝐾 − Factor Representing Relative Compressibility

𝑔 − Gravitational Constant (32.2(ft/sec2))

Case Guide

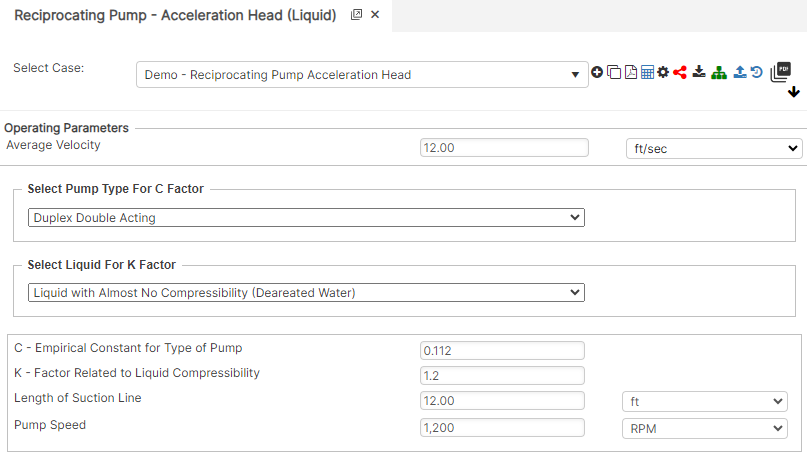

Part 1: Create Case

- Select the Reciprocating Pump – Piston Rod Load application from the Pump Module

- To create a new case, click the “Add Case” button

- Enter Case Name, Location, Date and any necessary notes.

- Fill out all required Parameters.

- Make sure the values you are inputting are in the correct units.

- Click the CALCULATE button to overview results.

Input Parameters

- Pump Type (C – Empirical Constant for Type of Pump)

- Liquid Type (K – Factor Related to Liquid Compressibility)

- Length of Suction Line (ft)

- Average Liquid Velocity (ft/sec)

- Pump Speed (rpm)

Part 2: Outputs/Reports

- If you need to modify an input parameter, click the CALCULATE button after the change.

- To SAVE, fill out all required case details then click the SAVE button.

- To rename an existing file, click the SAVE As button. Provide all case info then click SAVE.

- To generate a REPORT, click the REPORT button.

- The user may export the Case/Report by clicking the Export to Excel icon.

- To delete a case, click the DELETE icon near the top of the widget.

Results

- Acceleration Head (ft)

References

- ASME B31.4 – 1998 Edition “Pipeline Transportation Systems for Liquid Hydrocarbons and other Liquids”, Art. 404.1

- API 1117 – Movement of In-Service Pipelines

- API 5L, API 5LS and API 5LX – Specification of Pipe Grade

- ASTM – Various – Weld Joint Factor

- CFR Code Part 192

- MMS Regulations

- USDA-SCS Modified (Permissible Velocity of Water and Soil Erodibility)

- Pipeline Rules of Thumb Handbook