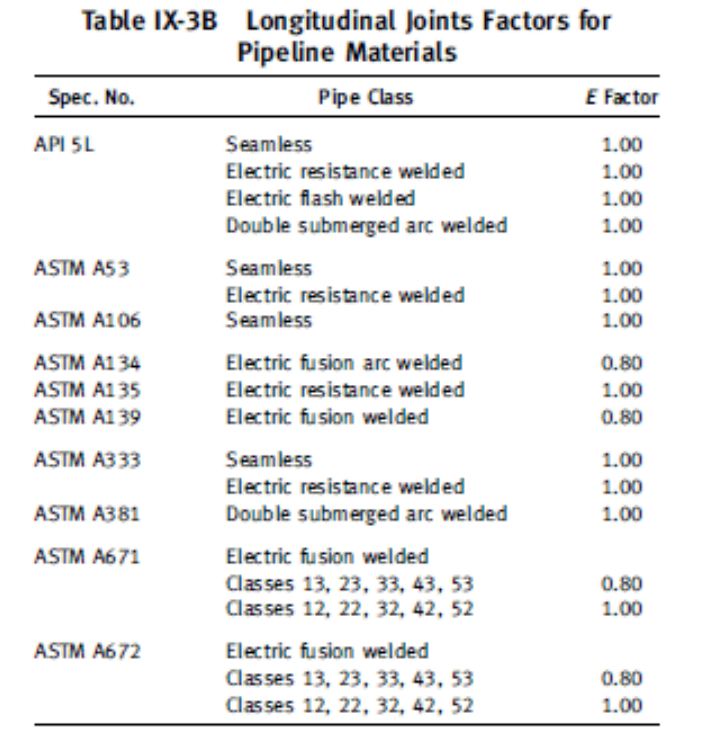

Longitudinal Weld Joint Efficiency Factor, E

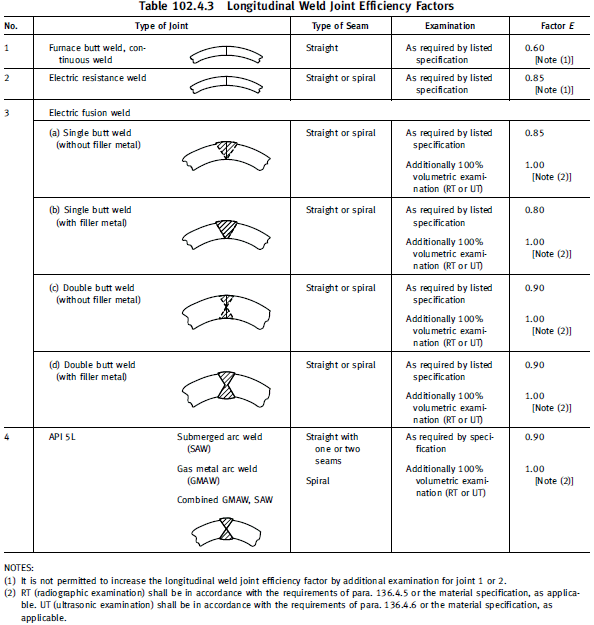

ASME B31.1: Table 102.4.3 (E factor)

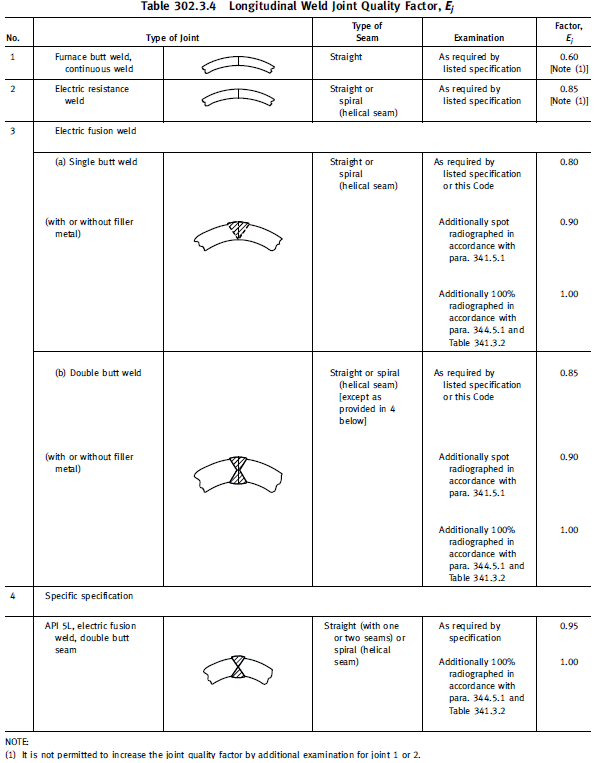

ASME B31.3: Table 302.3.4 (Ej factor)

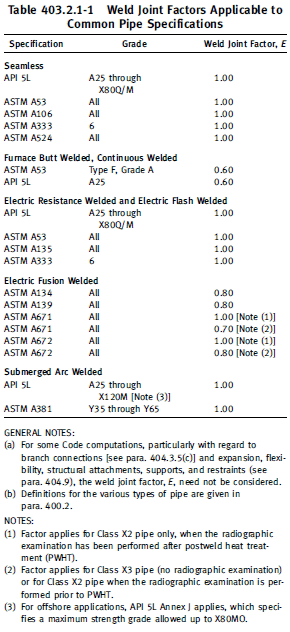

ASME B31.4: Table 403.2.1-1 (E factor)

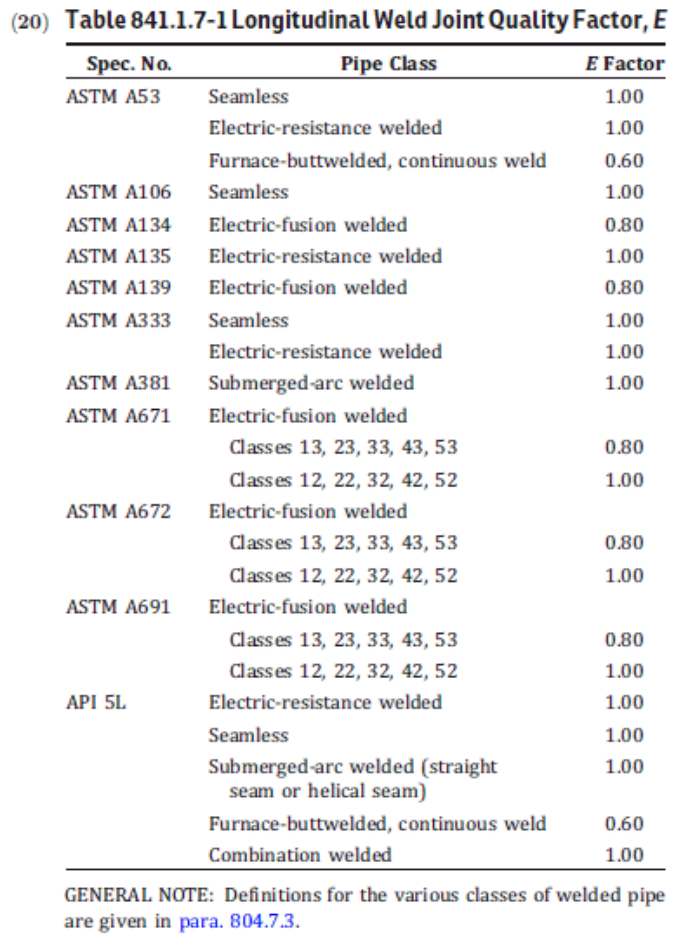

ASME B31.8: Table 841.1.7-1 (E factor)

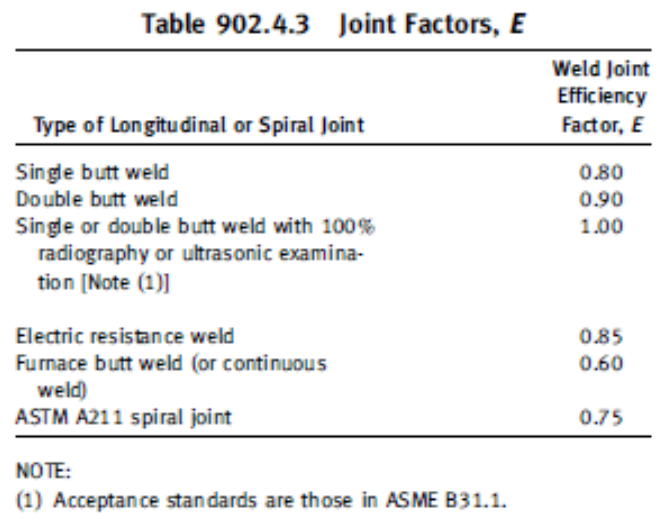

ASME B31.9: Table 902.4.3(E factor)

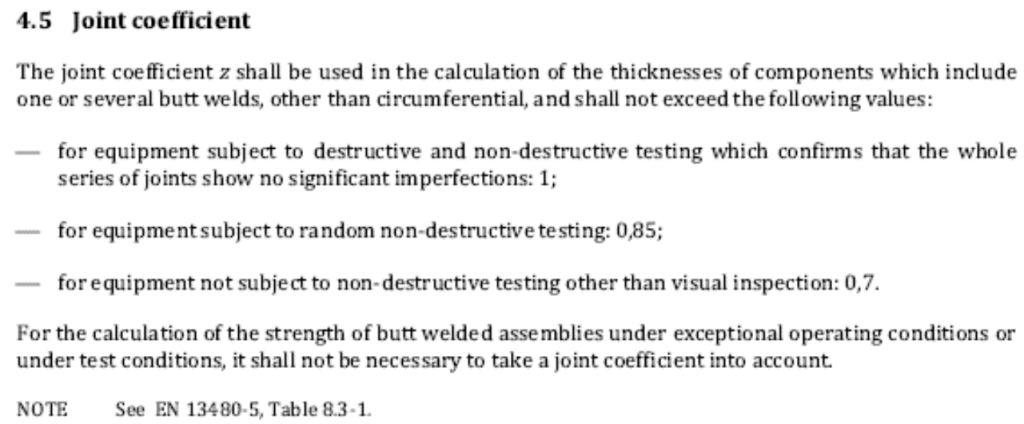

EN 13480, EN 13941: “Joint Coefficient, Z” p. 4.5

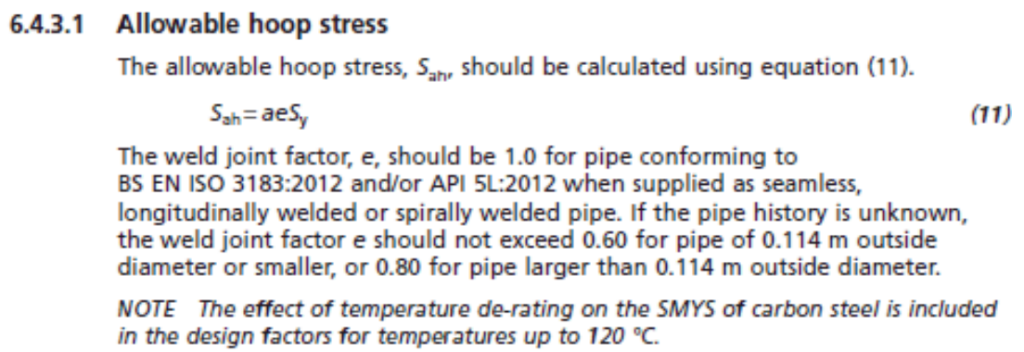

BS PD 8010: “weld joint factor, e”, 6.4.3.1

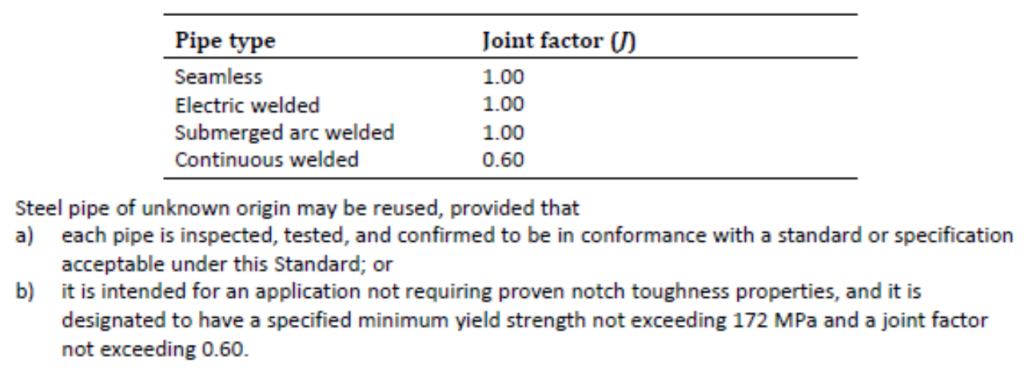

CSA Z662: “Joint Factor, J” 4.3.5.1

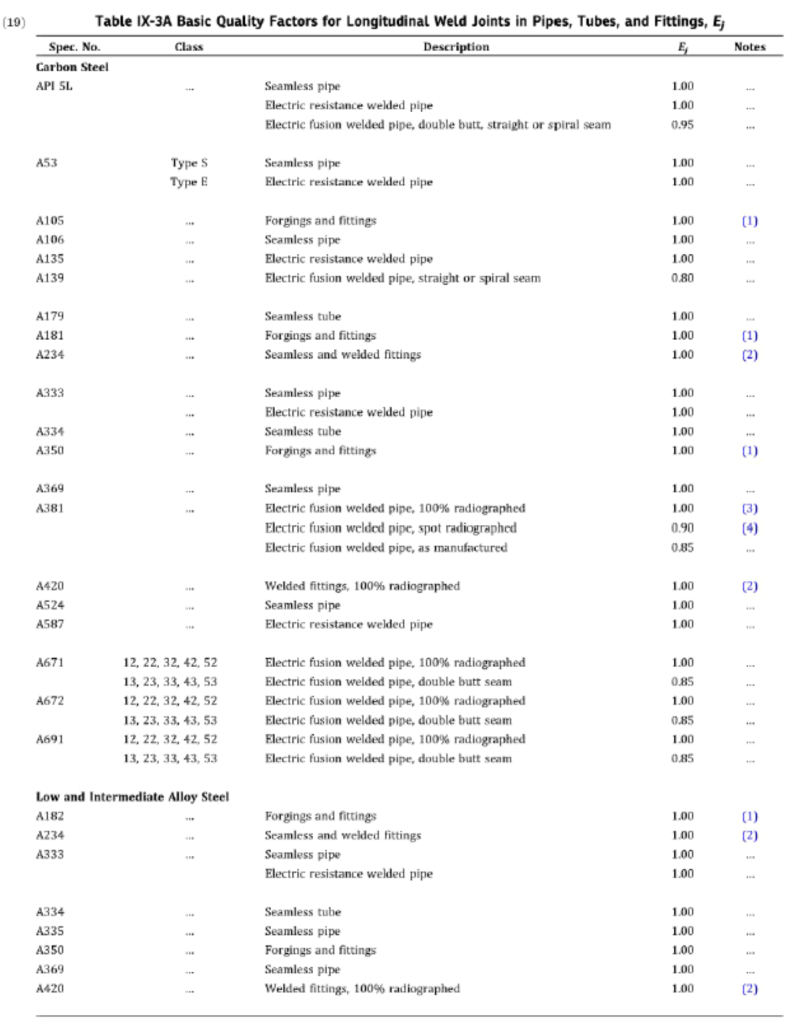

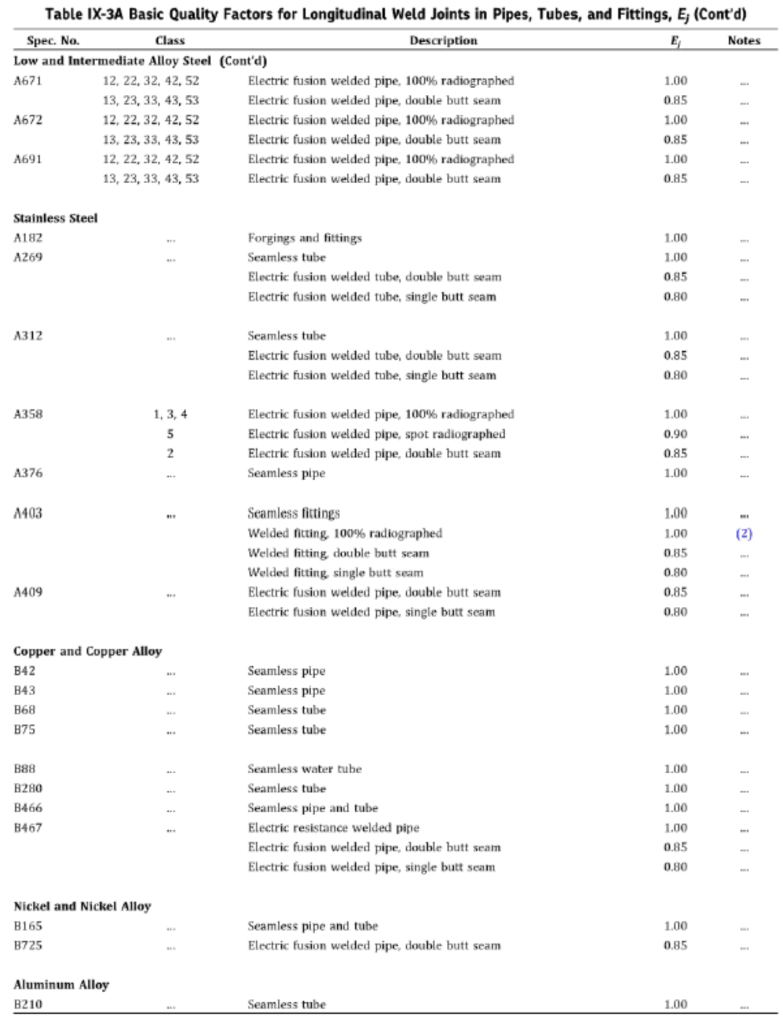

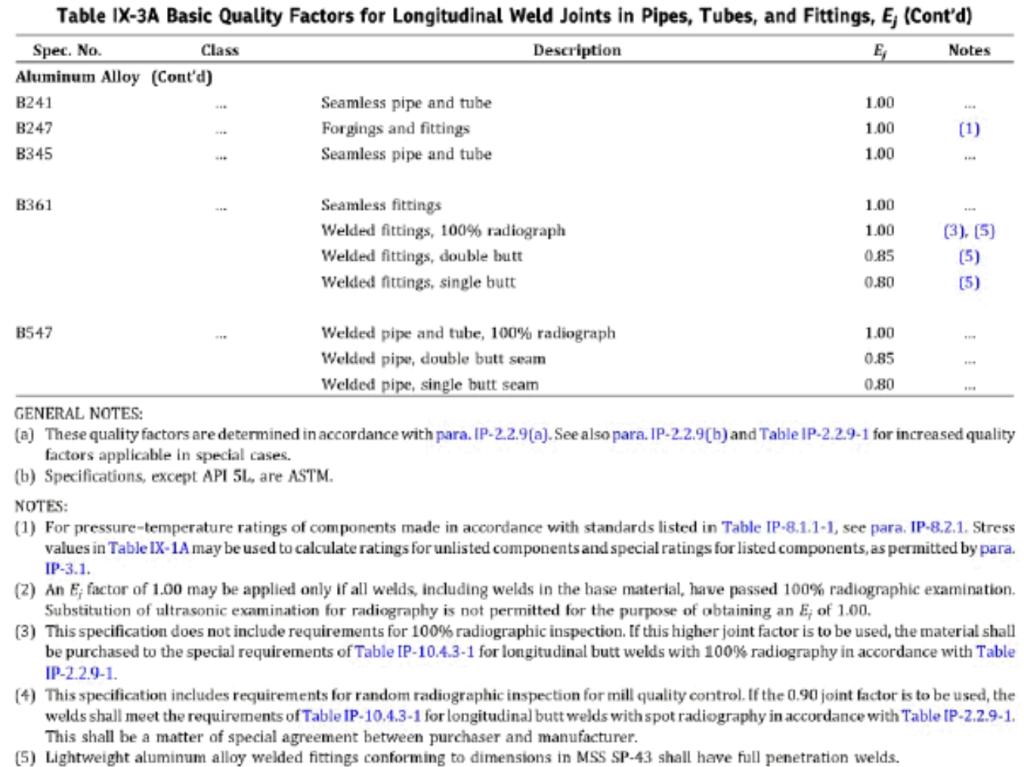

ASME B31.12 IP:

ASME B31.12 PL:

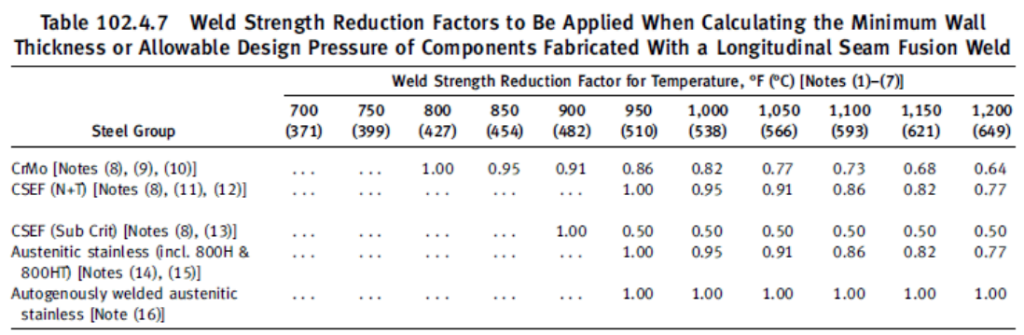

Weld Safety Factor for Pressure (longitudinal), WI

START-PROF use these factors only for checking the wall thicknesses to pressure load in ASME B31.1, ASME B31.3, DL/T 5366.

Wl factors automatically got from material database, you don’t have to specify it in input data.

ASME B31.1:

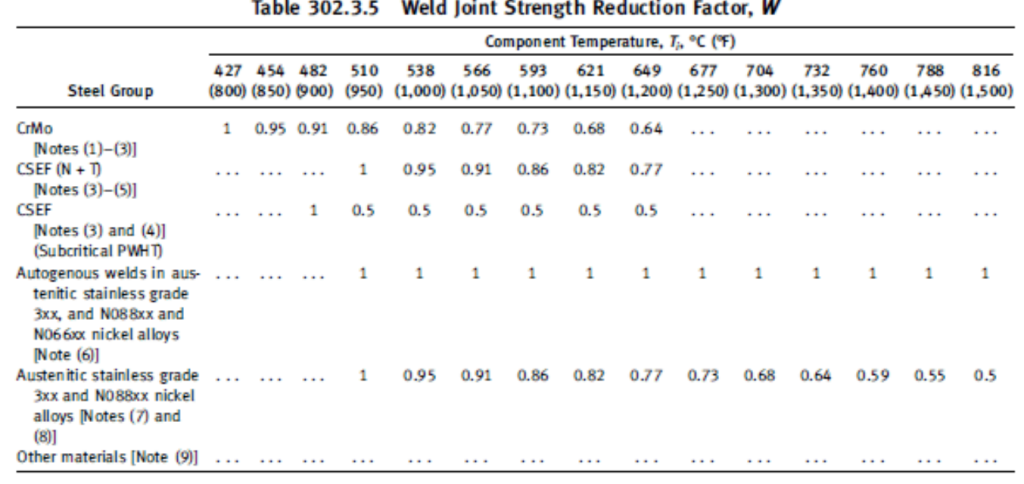

ASME B31.3:

Weld Safety Factor for Bending (circumferential), Wc

ASME B31.1 102.4.7 “The designer is responsible to assess application of weld strength reduction factor requirements for welds other than longitudinal and spiral, as applicable (e.g., circumferential welds).”

ASME B31.3 302.3.5 (e) “The designer is responsible for the application of weld joint strength reduction factors to welds other than longitudinal and spiral (helical seam) (e.g., circumferential)”.

START-PROF multiply sustained allowable stress by Wc factor if option “Use Wc factors” is activated in Project Settings. Allowable stress for occasional and expansion loads are not multiplied by Wc.

Wc factors automatically got from material database and equal to Wl factors.